Industrial Suppliers Guide to Premium Double Welding Hose Solutions

For industrial operations requiring reliable gas delivery systems, Double Welding Hose solutions offer unmatched efficiency and safety. Hebei Kebing Import And Export Trade Co., LTD specializes in providing premium-grade Oxy Acetylene Hose configurations designed for demanding welding and cutting applications. Our Hose Oxygen Acetylene products combine advanced materials engineering with practical design features to meet rigorous industrial standards. Whether you require traditional separate hoses or integrated Double Welding Hose assemblies, our solutions deliver optimal performance across temperature extremes and challenging work environments. The carefully engineered Oxy Acetylene Hose systems feature reinforced construction while maintaining flexibility, and our color-coded Hose Oxygen Acetylene options ensure proper gas identification. Trust Hebei Kebing Import And Export Trade Co., LTD for durable, safety-compliant hose solutions that enhance productivity in industrial gas applications.

Understanding the Critical Role of Oxy Acetylene Hose in Industrial Applications

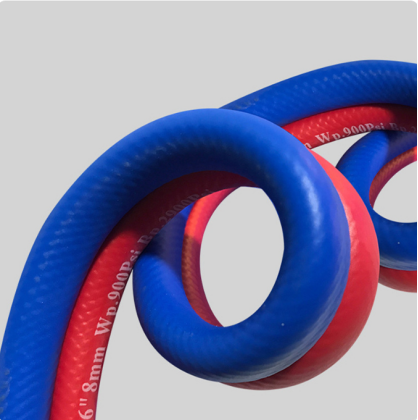

The Oxy Acetylene Hose serves as the backbone of welding and cutting operations across industries. Designed with precision, these hoses feature a flame-resistant outer layer and high-tensile reinforcement to ensure safe transportation of combustible gases. At Hebei Kebing Import And Export Trade Co., LTD, we emphasize the importance of using properly color-coded Oxy Acetylene Hose systems - red for fuel gases and blue for oxygen - to prevent dangerous mix-ups during high-temperature operations. The synthetic rubber construction provides exceptional flexibility while maintaining structural integrity under pressure, making these hoses ideal for demanding industrial environments where reliability cannot be compromised.

Hose Oxygen Acetylene Systems Engineering for Safety and Performance

Modern Hose Oxygen Acetylene configurations represent significant advancements in gas delivery technology. These specialized hoses incorporate multiple protective layers, including an abrasion-resistant cover and reinforced textile braiding, to withstand the rigors of continuous industrial use. What sets premium Hose Oxygen Acetylene products apart is their ability to minimize gas permeability while remaining remarkably flexible. Hebei Kebing Import And Export Trade Co., LTD supplies these critical components with enhanced ozone and weather resistance properties, ensuring consistent performance whether in sweltering workshop conditions or freezing outdoor job sites. The smooth inner bore design reduces turbulence, allowing for optimal gas flow during precision welding operations.

For wholesale buyers, understanding the construction of these hoses is vital. A Double Welding Hose often features:

|

Component |

Material/Feature |

Application |

|

Tube |

ยางสังเคราะห์สีดำเรียบ |

Inner layer for gas containment |

|

Reinforcement |

High-strength synthetic yarn braiding |

Enhances durability and pressure resistance |

|

Cover |

สีฟ้า/เขียว/แดง ผิวเรียบ ยางสังเคราะห์ |

Color-coded for gas identification (blue for oxygen, red for acetylene) |

These hoses are designed for welding, cutting, and allied processes, catering to gases like oxygen, carbon dioxide, nitrogen, and fuel gases such as acetylene and propane. Key characteristics include anti-abrasion covers, weather resistance, and flexibility, making them ideal for demanding industrial environments.

Double Welding Hose The Efficient Solution for Professional Workshops

The innovative Double Welding Hose design revolutionizes gas management by combining oxygen and fuel gas delivery into a single, integrated unit. This configuration offers numerous advantages for bulk purchasers, including reduced tripping hazards and simplified inventory management. The Double Welding Hose from Hebei Kebing Import And Export Trade Co., LTD features parallel tubes with distinct color coding, maintaining strict separation between gases while providing the convenience of a unified assembly. Particularly valuable in high-volume operations, these hoses demonstrate exceptional resistance to kinking and abrasion, significantly extending service life compared to conventional single hoses. Their lightweight construction reduces operator fatigue during extended use, a crucial consideration for industrial-scale operations.

Selecting Between Oxy Acetylene Hose and Double Welding Hose Systems

Choosing between traditional Oxy Acetylene Hose setups and modern Double Welding Hose solutions depends on specific operational requirements. While separate Oxy Acetylene Hose assemblies offer maximum flexibility for custom configurations, the integrated Double Welding Hose provides streamlined efficiency for standardized applications. Hebei Kebing Import And Export Trade Co., LTD advises bulk buyers to consider workspace layout, frequency of equipment movement, and gas compatibility requirements when making this critical decision. Both options maintain the essential safety features of flame-resistant materials and pressure-rated construction, but the Double Welding Hose often proves more economical for operations requiring frequent hose repositioning or limited storage space.

FAQS about Oxy Acetylene Hose

What maintenance does an oxy acetylene hose require?

Proper care for your Oxy Acetylene Hose includes regular inspections for cracks or abrasions, keeping the hose away from sharp edges, and storing it properly coiled without kinks. Always check connections for leaks before use and replace the hose at first signs of wear to maintain safety standards in welding operations.

How does hose oxygen acetylene differ from regular air hoses?

The Hose Oxygen Acetylene features specialized construction with multiple reinforcement layers and gas-specific materials that resist combustion, unlike standard air hoses. These hoses undergo rigorous testing to prevent gas permeation and maintain integrity under the unique pressures and temperatures of welding applications.

When should I choose a double welding hose over separate hoses?

A Double Welding Hose becomes advantageous when workspace organization and efficiency are priorities. The integrated design reduces clutter, minimizes trip hazards, and simplifies setup - particularly beneficial for operations requiring frequent equipment movement or working in confined spaces.

What safety certifications should quality oxy acetylene hose possess?

Reputable Oxy Acetylene Hose products should carry certifications confirming flame resistance, pressure ratings, and material compatibility. Hebei Kebing Import And Export Trade Co., LTD supplies hoses meeting international standards for welding equipment, with documentation available for bulk purchasers' compliance records.

Can double welding hose be repaired if damaged?

While minor damage to a Double Welding Hose might seem repairable, industry standards typically recommend complete replacement. The integrated gas channels and critical safety requirements make repairs potentially hazardous, and compromised hoses should be immediately taken out of service to prevent accidents.

-

Advanced Corrugated Pvc Hose Technology for Modern Industrial Needsข่าวAug.22,2025

-

Premium Fire Water Hose Solutions for Global Industriesข่าวAug.22,2025

-

Industrial Suppliers Guide to Premium Double Welding Hose Solutionsข่าวAug.22,2025

-

Premium PU Pneumatic Hose Solutions for Industrial Applicationsข่าวAug.22,2025

-

Wholesale PVC Garden Hose China Solutions for Global Buyersข่าวAug.22,2025

-

Wire Reinforced PVC Tubing Solutions for Global Industrial Applicationsข่าวAug.20,2025