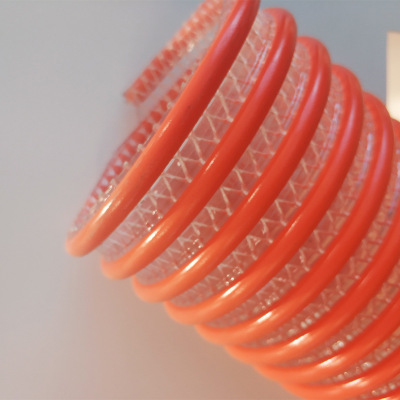

PVC Fibre Reinforced Suction Hose

PRODUCT DETAILS

A PVC fiber-reinforced hose production line is a collection of specialized equipment used to manufacture PVC fiber-reinforced hose (also known as PVC mesh pipe or snake skin pipe).

Non-toxic, transparent, pressure-resistant, tensile-resistant, acid-and-alkali-resistant, corrosion-resistant, beautiful, light, and durable, PVC fiber-reinforced hose is ideal for transporting pressurized or corrosive gases and liquids.

This line is ideal for producing PVC fiber-reinforced hose. PVC mesh hose, also known as plastic snake hose, is another name for PVC fiber-reinforced hose.

The hose is made of three layers. PVC soft plastic is used for the inner and outer layers, and polyester fiber-reinforced mesh, which has good mechanical and chemical properties, is used for the middle layer.

It is widely used in machinery, coal, petroleum, chemistry, irrigation, construction, and civil fields (solar water heaters, gas tanks), and it is also frequently used in garden and lawn irrigation, among other things.

The ext-ruder, cooling water tank, tractor, winding machine, coiled, and other components comprise the PVC fiber-reinforced hose production line. Most users welcome and trust it due to its reasonable support, unique structure, reliable performance, simple operation, convenient maintenance, and continuous solid production capacity.

Application:

This hose is widely used for fish suction,irrigation lines,pumps,rental and construction dewatering.

Also for trash suction and discharge; heavy duty water suction etc

Working temperature range:

-10 °C to +65 °C

Features:

Designed with high tensile strength polyester fibre to handle both suction and higher pressure discharge applications.

Transparent construction allows to see the flow of the materials inside the hose

Rigid pvc helix design protects hose from external abrasion

Easy-to-handle

Material:

Tube:double-ply PVC

Reinforcement: polyester fibre

Helix: rigid PVC

|

size |

ID |

OD |

Bending Radius |

Working Pressure |

Weight |

Length |

|

|

inch |

mm |

mm |

mm |

psi |

bar |

Kg/m |

m/roll |

|

2 |

51 |

66 |

250 |

90 |

6 |

1.1 |

30 |

|

2-1/2 |

64 |

71 |

300 |

75 |

5 |

1.6 |

30 |

|

3 |

76 |

92 |

300 |

60 |

4 |

2.2 |

30 |

|

4 |

102 |

121 |

400 |

60 |

4 |

3 |

30 |

|

5 |

127 |

152 |

600 |

60 |

4 |

4 |

20 |

|

6 |

152 |

180 |

750 |

45 |

3 |

5.7 |

20 |

|

8 |

203 |

232 |

920 |

40 |

3 |

8.4 |

10 |

|

10 |

254 |

282 |

|

40 |

3 |

14 |

10 |

|

12 |

304 |

345 |

|

30 |

2 |

19 |

10 |

PRODUCT DISPLAY

Product production and packaging: