lut . 03, 2025 02:05

Back to list

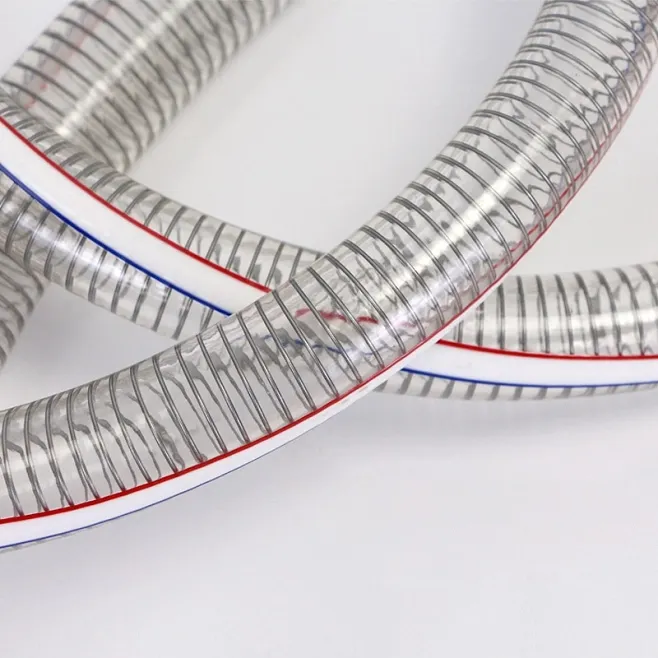

pvc vs rubber vs polyurethane air hose

Choosing the right air hose for your industrial or domestic needs can greatly impact the performance and durability of air tools and compressor systems. Three of the most popular materials for air hoses are PVC, rubber, and polyurethane, each with unique properties that cater to different applications. Drawing from extensive experience in the industry, this article delves into the comparative analysis of PVC, rubber, and polyurethane air hoses, emphasizing their advantages, disadvantages, and best-use scenarios to guide you in making an informed decision.

Polyurethane Air Hoses Lightweight and Versatile Polyurethane hoses strike a balance between the lightweight properties of PVC and the flexibility of rubber. These hoses are highly flexible, retaining their shape and performance even in varying temperatures, which makes them suitable for both indoor and outdoor use. Polyurethane air hoses also resist abrasion and are less prone to dragging wear, ensuring a longer lifespan in environments with frequent hose movement. One of the notable drawbacks of polyurethane hoses is their potentially higher cost relative to PVC options. However, for those who require a light, durable, and flexible hose, polyurethane presents a worthwhile investment. Additionally, polyurethane hoses are less susceptible to kinking, which enhances their utility in precision-driven applications. Expert Recommendations and Applications For budget-conscious consumers or light-duty tasks, PVC air hoses offer an affordable and adequate solution. They excel in environments where visibility is important and weight should be minimized. Yet, for professional workshops or industrial environments, rubber hoses are renowned for their durability and ability to withstand rigorous use and challenging conditions, making them the preferred choice for users who prioritize robustness. In scenarios demanding a balance of flexibility and material strength without the heavier weight of rubber, polyurethane hoses emerge as the optimal choice. They are particularly beneficial in dynamic work situations, such as construction sites or automotive repair shops, where tool precision and mobility are key. In conclusion, the selection between PVC, rubber, and polyurethane air hoses should be guided by a clear understanding of specific work requirements, weighing factors such as cost, flexibility, durability, and environmental conditions. By focusing on these criteria, users can optimize the operational efficiency and lifespan of their air systems, ensuring they meet their needs in the most effective manner possible. Whether for industrial applications or household tasks, choosing the right air hose is pivotal to achieving reliable performance and maximum utility.

Polyurethane Air Hoses Lightweight and Versatile Polyurethane hoses strike a balance between the lightweight properties of PVC and the flexibility of rubber. These hoses are highly flexible, retaining their shape and performance even in varying temperatures, which makes them suitable for both indoor and outdoor use. Polyurethane air hoses also resist abrasion and are less prone to dragging wear, ensuring a longer lifespan in environments with frequent hose movement. One of the notable drawbacks of polyurethane hoses is their potentially higher cost relative to PVC options. However, for those who require a light, durable, and flexible hose, polyurethane presents a worthwhile investment. Additionally, polyurethane hoses are less susceptible to kinking, which enhances their utility in precision-driven applications. Expert Recommendations and Applications For budget-conscious consumers or light-duty tasks, PVC air hoses offer an affordable and adequate solution. They excel in environments where visibility is important and weight should be minimized. Yet, for professional workshops or industrial environments, rubber hoses are renowned for their durability and ability to withstand rigorous use and challenging conditions, making them the preferred choice for users who prioritize robustness. In scenarios demanding a balance of flexibility and material strength without the heavier weight of rubber, polyurethane hoses emerge as the optimal choice. They are particularly beneficial in dynamic work situations, such as construction sites or automotive repair shops, where tool precision and mobility are key. In conclusion, the selection between PVC, rubber, and polyurethane air hoses should be guided by a clear understanding of specific work requirements, weighing factors such as cost, flexibility, durability, and environmental conditions. By focusing on these criteria, users can optimize the operational efficiency and lifespan of their air systems, ensuring they meet their needs in the most effective manner possible. Whether for industrial applications or household tasks, choosing the right air hose is pivotal to achieving reliable performance and maximum utility.

Next:

Latest news

-

Top Quality Oxy Acetylene Hoses for Sale Fit for Welding DemandsNewsJul.28,2025

-

The Future of Pneumatic Air Tubes in IndustryNewsJul.28,2025

-

Superior and Reliable LPG Hose Pipe Solutions for Every NeedNewsJul.28,2025

-

Exceptionally Durable and Versatile Premium Braided PVC TubingNewsJul.28,2025

-

Best Adapters for Connecting Garden Hose to PVC Pipe ConnectionsNewsJul.28,2025

-

The Essential Role of LPG Hoses in Safe and Efficient Gas DistributionNewsJul.16,2025

HOT PRODUCT

Provide You The Highest Quality Work

INQUIRE