2월 . 12, 2025 20:34

Back to list

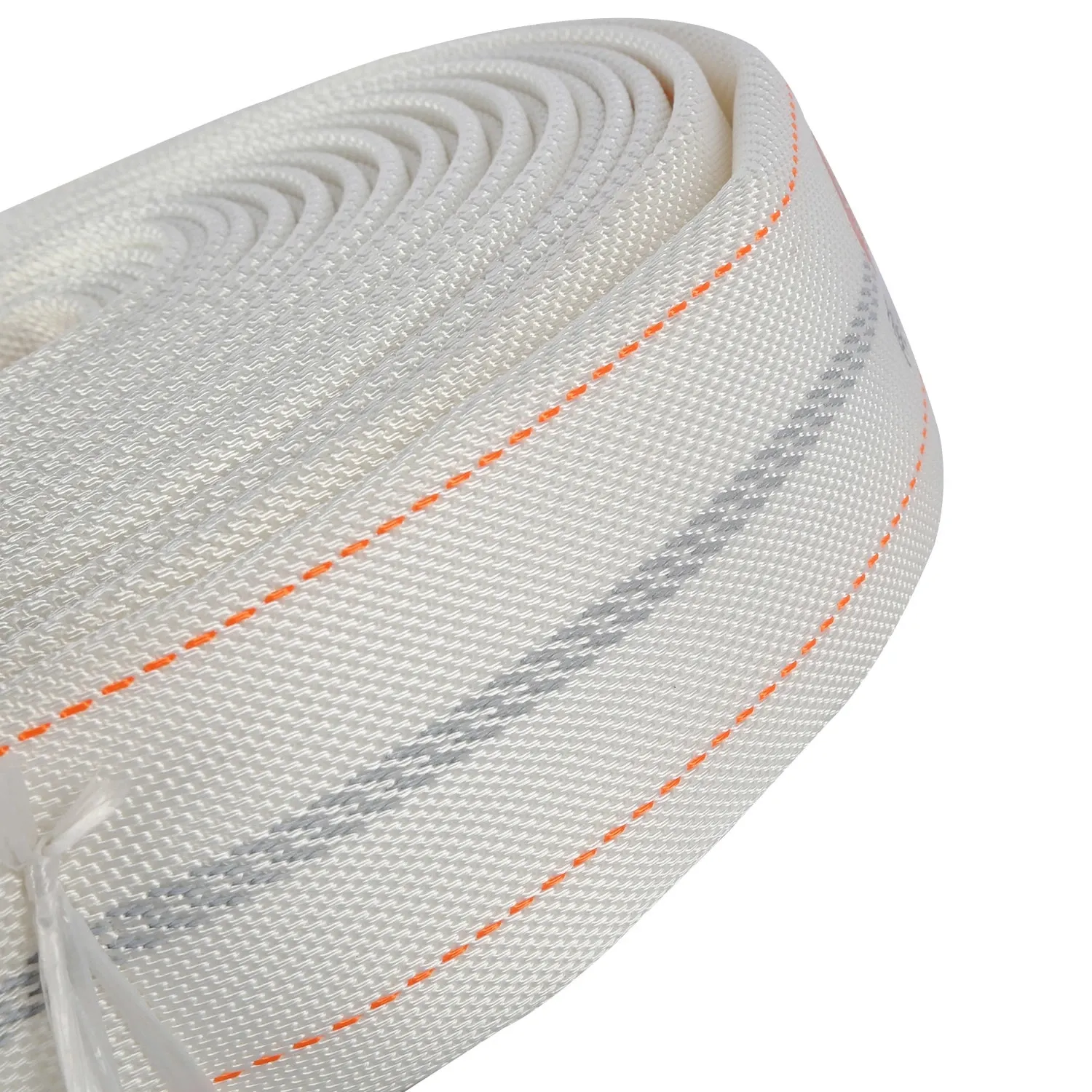

vacuum insulated tubing manufacturer

In the rapidly evolving energy sector, efficiency and safety are paramount, especially in oil and gas extraction and transportation. Vacuum insulated tubing (VIT) technology has been a groundbreaking advancement in this field. VIT offers superior thermal insulation capabilities, which are critical in maintaining product integrity and maximizing operational efficiency. Choosing a reliable vacuum insulated tubing manufacturer can make a significant impact on the success of energy projects. Herein, we delve into the facets of VIT manufacturing that underscore experience, expertise, authoritativeness, and trustworthiness.

Trustworthiness is a critical pillar that ties together a manufacturer's experience, expertise, and authoritativeness. Trust is built over time through consistent delivery of high-performance products and excellent customer service. Manufacturers that prioritize open communication, transparent project timelines, and after-sales support tend to foster stronger relationships with their clients. They often have robust feedback mechanisms in place to capture and integrate client insights into product and process improvements. The reliability of delivery schedules and adherence to budget constraints further reinforces client confidence in the manufacturer's capabilities. Moreover, a truly trustworthy vacuum insulated tubing manufacturer invests in sustainable practices and prioritizes environmental responsibility. This commitment is not merely an ethical choice but a strategic advantage, as reducing ecological footprints aligns with global energy conservation goals. From utilizing eco-friendly materials to implementing energy-efficient production methodologies, top-tier manufacturers are conscious of their impact on the environment and continuously seek innovative ways to enhance sustainability. In conclusion, selecting a vacuum insulated tubing manufacturer is a decision of paramount importance in the oil and gas industry. To ensure project success and optimize operational efficiencies, stakeholders must evaluate potential partners based on their experience, expertise, authoritativeness, and trustworthiness. These indicators serve as reliable benchmarks for identifying a manufacturer whose products and services will consistently meet the high standards required for successful energy extraction and transportation. By collaborating with such a partner, companies can significantly advance their energy projects while maintaining a strong focus on safety, efficiency, and environmental stewardship.

Trustworthiness is a critical pillar that ties together a manufacturer's experience, expertise, and authoritativeness. Trust is built over time through consistent delivery of high-performance products and excellent customer service. Manufacturers that prioritize open communication, transparent project timelines, and after-sales support tend to foster stronger relationships with their clients. They often have robust feedback mechanisms in place to capture and integrate client insights into product and process improvements. The reliability of delivery schedules and adherence to budget constraints further reinforces client confidence in the manufacturer's capabilities. Moreover, a truly trustworthy vacuum insulated tubing manufacturer invests in sustainable practices and prioritizes environmental responsibility. This commitment is not merely an ethical choice but a strategic advantage, as reducing ecological footprints aligns with global energy conservation goals. From utilizing eco-friendly materials to implementing energy-efficient production methodologies, top-tier manufacturers are conscious of their impact on the environment and continuously seek innovative ways to enhance sustainability. In conclusion, selecting a vacuum insulated tubing manufacturer is a decision of paramount importance in the oil and gas industry. To ensure project success and optimize operational efficiencies, stakeholders must evaluate potential partners based on their experience, expertise, authoritativeness, and trustworthiness. These indicators serve as reliable benchmarks for identifying a manufacturer whose products and services will consistently meet the high standards required for successful energy extraction and transportation. By collaborating with such a partner, companies can significantly advance their energy projects while maintaining a strong focus on safety, efficiency, and environmental stewardship.

Next:

Latest news

-

Top Quality Oxy Acetylene Hoses for Sale Fit for Welding DemandsNewsJul.28,2025

-

The Future of Pneumatic Air Tubes in IndustryNewsJul.28,2025

-

Superior and Reliable LPG Hose Pipe Solutions for Every NeedNewsJul.28,2025

-

Exceptionally Durable and Versatile Premium Braided PVC TubingNewsJul.28,2025

-

Best Adapters for Connecting Garden Hose to PVC Pipe ConnectionsNewsJul.28,2025

-

The Essential Role of LPG Hoses in Safe and Efficient Gas DistributionNewsJul.16,2025

HOT PRODUCT

Provide You The Highest Quality Work

INQUIRE