PVC Suction Hoses: Flexible, Durable Fluid Transfer Solutions

Understanding PVC Suction Hoses: Industry Trends and Innovations

The global market for industrial hoses, including pvc suction hoses, is experiencing robust growth, driven by expansion in manufacturing, construction, agriculture, and water management sectors. PVC (Polyvinyl Chloride) suction hoses are critical components in fluid transfer systems, known for their exceptional flexibility, durability, and resistance to various chemicals and abrasives. Current industry trends emphasize enhanced material composites for improved performance, greater sustainability through recycled content, and smart monitoring capabilities for predictive maintenance.

Innovations are focusing on increasing pressure ratings, optimizing weight-to-performance ratios, and developing specialized linings for highly corrosive or abrasive media. The demand for lightweight yet robust solutions, such as pvc suction hose pipe 2 inch variants, is particularly high in portable pumping applications. Furthermore, the market sees a growing interest in customized solutions that address specific operational challenges, ranging from extreme temperature resilience to static dissipation requirements.

The Advanced Manufacturing Process of PVC Suction Hoses

The production of high-quality pvc suction hoses is a sophisticated process involving precise material formulation and advanced extrusion techniques. The objective is to ensure optimal structural integrity, flexibility, and resistance properties for demanding industrial applications.

Material Selection and Compounding

The foundation of a superior PVC hose lies in its raw materials. High-grade PVC resin is combined with various additives, including plasticizers for flexibility, UV stabilizers for weather resistance, anti-aging agents, and colorants. For enhanced abrasion resistance, specific reinforcing compounds may be incorporated. The exact formulation is crucial and often tailored to meet specific performance criteria, such as those required for a clear pvc suction hose where transparency and chemical inertness are key.

Extrusion and Reinforcement

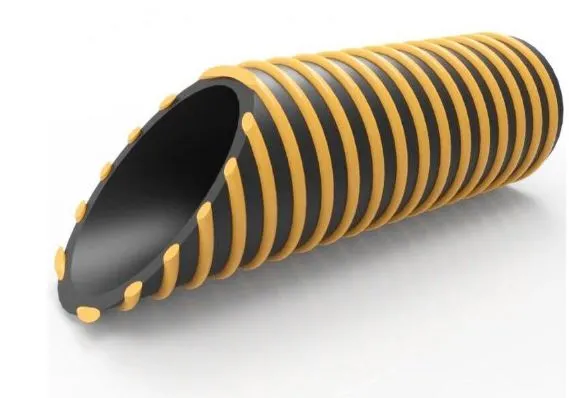

The compounded PVC material is fed into a high-precision extruder, where it is heated and melted. The molten PVC is then forced through a die to form the hose's inner and outer layers. For suction applications, reinforcement is vital to prevent collapse under vacuum and provide burst strength. This is typically achieved by embedding a rigid PVC helix (spiral) or textile braiding between two layers of flexible PVC during the co-extrusion process. Advanced CNC machining is employed for precise die manufacturing, ensuring consistent wall thickness and internal diameter (ID).

Cooling and Curing

Immediately after extrusion and reinforcement, the hose enters a cooling bath, typically filled with water, to solidify the PVC structure and lock in its physical properties. Controlled cooling rates are essential to prevent material stress and ensure dimensional stability. Some specialized hoses may undergo further curing processes to enhance specific characteristics like chemical resistance or flexibility.

Rigorous Quality Control and Testing

Every batch of pvc suction hoses undergoes stringent quality control testing to comply with international standards such as ISO 1307 (Rubber and plastics hoses – Hose sizes, minimum and maximum inside diameters, and tolerances on cut-to-length hoses) and relevant ANSI specifications for burst pressure and vacuum ratings. Key tests include:

- Pressure Testing: Hoses are subjected to internal pressures significantly higher than their rated working pressure to verify burst strength.

- Vacuum Testing: Evaluates resistance to collapse under negative pressure, ensuring efficient suction capabilities.

- Flexibility and Kink Resistance: Manual and automated tests confirm the hose's ability to bend without kinking, crucial for practical deployment.

- Dimensional Stability: Inner and outer diameters, wall thickness, and length are measured precisely.

- Material Analysis: Verification of material composition and absence of harmful substances.

Service Life and Target Industries

With proper installation and maintenance, a high-quality pvc suction hoses can offer a service life of 5-10 years, depending on the application severity and environmental conditions. Our hoses are engineered for robust performance in demanding sectors, including:

- Petrochemical: Transfer of various oils, fuels, and chemical slurries.

- Metallurgy: Slurry and abrasive material transfer in mineral processing.

- Water Supply & Drainage: Municipal water transfer, dewatering, and flood control.

- Landbrug: Irrigation, liquid fertilizer transfer, and grain handling.

- Konstruktion: Concrete pumping, aggregate transfer, and site dewatering.

- Mining: Slurry and tailings transport, ventilation.

Technical Specifications and Performance Parameters

Understanding the technical specifications of pvc suction hoses is crucial for selecting the appropriate product for specific industrial applications. Key parameters include internal diameter (ID), wall thickness, working pressure, burst pressure, vacuum rating, operating temperature range, and bend radius.

High-Quality PVC Grit Suction Hose Specifications (Example: 51mm ID, 30m Length)

| Parameter | Specification | Unit |

|---|---|---|

| Product Name | High Quality PVC Grit Suction Hose | - |

| Internal Diameter (ID) | 51 | mm (2 inch) |

| Standard Length | 30 | m |

| Material | Flexible PVC with Rigid PVC Helix | - |

| Arbejdspres | 0.5 - 1.0 (Approximate, varies by wall thickness) | MPa |

| Burst Pressure | ≥ 3.0 (Approximate) | MPa |

| Vacuum Rating | -0.08 to -0.09 (Full Vacuum) | MPa |

| Operating Temperature | -10 to +60 | °C |

| Flexibility | Excellent | - |

| Abrasion Resistance | High | - |

| Chemical Resistance | Good (to most acids, alkalis, and many solvents) | - |

The pvc suction hose pipe price often reflects the quality of raw materials and the manufacturing precision that goes into achieving these robust specifications. Investing in a hose that meets or exceeds these parameters ensures operational efficiency and longevity.

Application Scenarios and Technical Advantages

The versatility of pvc suction hoses makes them indispensable across a multitude of industrial and commercial applications. Their inherent properties provide distinct technical advantages over other hose types.

Typical Application Scenarios

- Agriculture and Irrigation: Transfer of water, slurries, and liquid fertilizers. Its light weight and flexibility make it ideal for field use.

- Construction and Mining: Dewatering, sludge transfer, conveying aggregates, and ventilating confined spaces.

- Industrial Wastewater: Suction and discharge of industrial effluents, often containing abrasive particles or corrosive chemicals.

- Food and Beverage Industry: Specific food-grade PVC hoses are used for transferring potable water, liquid foods, and spirits, adhering to FDA standards.

- Marine and Aquaculture: Bilge pumping, fish transfer, and general water handling on boats and fish farms.

- Vacuum Systems: Industrial vacuum cleaning, chip collection, and material handling in woodworking shops.

Key Technical Advantages

- Corrosion Resistance: PVC is inherently resistant to a wide range of chemicals, including many acids, alkalis, and salt solutions, preventing degradation and ensuring long-term performance even in harsh chemical environments. This significantly reduces maintenance and replacement costs compared to metallic alternatives.

- Excellent Abrasion Resistance: Especially for grit suction hoses, the robust PVC construction with a rigid helix provides superior resistance to wear from abrasive materials like sand, gravel, and industrial waste.

- Flexibility and Kink Resistance: The spiral reinforcement combined with flexible PVC allows for significant bending without kinking or collapsing under vacuum, making installation and maneuvering in tight spaces much easier. This contributes to energy saving by maintaining consistent flow and reducing pump strain.

- Lightweight Design: PVC hoses are significantly lighter than rubber or composite hoses of similar specifications, enhancing portability and reducing physical strain during deployment and retrieval.

- Transparency (for clear variants): A clear pvc suction hose allows operators to visually monitor fluid flow, detect blockages, or identify changes in transferred material, which is invaluable for process control and troubleshooting.

- Cost-Effectiveness: When considering the pvc suction hose pipe price versus its performance and durability, PVC hoses offer an excellent economic value proposition, providing reliable service without the higher initial investment of specialized rubber or metal hoses.

- Wide Temperature Range: Capable of operating effectively across a broad temperature spectrum, typically from -10°C to +60°C, accommodating diverse environmental conditions.

Vendor Comparison and Customized Solutions

When sourcing pvc suction hoses, discerning buyers prioritize not just product specifications but also vendor capabilities, reliability, and support. A comprehensive vendor comparison highlights the importance of quality, customization, and long-term partnership.

Key Differentiators in Vendor Selection

| Feature | Standard Vendor Offerings | Kebing Hose Advantages |

|---|---|---|

| Material Quality | Standard industrial-grade PVC; may vary in plasticizer content. | Virgin PVC resin with advanced UV, anti-aging, and abrasion-resistant additives for extended service life. Food-grade options available (FDA compliant). |

| Manufacturing Precision | General extrusion, occasional inconsistencies in wall thickness. | High-precision co-extrusion with CNC-machined dies, ensuring uniform wall thickness and consistent ID for optimal flow. |

| Reinforcement Structure | Standard PVC helix; may be prone to fatigue. | Robust, impact-resistant rigid PVC helix embedded for superior vacuum resistance and crush protection. Optimized pitch for flexibility. |

| Certifications | Basic quality checks. | ISO 9001:2015 certified manufacturing, product testing to ISO 1307, adherence to FDA (for food-grade), and REACH/RoHS compliance. |

| Customization | Limited standard sizes and colors. | Extensive customization options: ID/OD, lengths, colors, material compounds (e.g., anti-static, flame retardant), fittings, private labeling. |

| Technical Support | Basic product information. | Dedicated engineering team for application-specific consulting, installation guidance, and troubleshooting. |

Tailored Customized Solutions

Recognizing that off-the-shelf solutions may not always meet unique operational demands, we specialize in providing bespoke pvc suction hoses. Our engineering team collaborates closely with clients to develop hoses that precisely fit specific requirements, encompassing:

- Diameter and Length: Production of pvc suction hose pipe 2 inch, 3 inch, or larger diameters, and custom lengths up to 100 meters per coil.

- Material Compounds: Formulation of PVC with enhanced properties like higher chemical resistance, increased UV stability, antistatic capabilities for explosive environments (e.g., ATEX zones), or extreme temperature resilience.

- Color and Transparency: Custom colors for brand identification or safety, and varying degrees of transparency, from opaque to highly clear pvc suction hose.

- Fittings and Assemblies: Pre-assembly with specific couplings (camlock, Bauer, threaded, etc.) and clamps to ensure a seamless integration into existing systems.

- Special Reinforcement: Dual helix designs or specialized textile braids for applications requiring extraordinary burst pressure or vacuum resistance.

Our commitment to customization ensures that clients receive not just a product, but a tailored solution optimized for their unique operating conditions, maximizing efficiency and minimizing downtime.

Application Case Studies & Customer Trust

Real-world application demonstrates the reliability and performance of our pvc suction hoses. Our extensive experience and authoritative certifications build a strong foundation of trust with our global clientele.

Case Study 1: Municipal Dewatering Project

Client: Major European Municipal Water Authority

Challenge: The client required a durable, flexible, and reliable hose for continuous dewatering operations during urban flood prevention and sewage system maintenance. Existing hoses suffered from rapid abrasion and kinking, leading to frequent replacements and operational interruptions. They needed a solution that could handle varying degrees of grit and debris, and withstand prolonged exposure to wastewater chemicals.

Solution: We supplied custom-length pvc suction hoses with enhanced abrasion resistance and a robust, anti-kink helix. The hoses were supplied with specialized quick-connect fittings for rapid deployment and retrieval.

Outcome: The new hoses demonstrated superior performance, lasting 2.5 times longer than previous solutions. Their anti-kink properties ensured uninterrupted flow, contributing to an estimated 15% reduction in pumping energy consumption and significantly fewer man-hours spent on hose management. The client lauded the reliability and cost-effectiveness, leading to a long-term supply contract.

Case Study 2: Industrial Chemical Transfer

Client: Leading Chemical Processing Plant in North America

Challenge: The plant needed a hose capable of safely transferring various corrosive industrial chemicals (diluted acids, alkalis) while being flexible enough for dynamic routing within their facility. Safety was paramount, demanding a hose with exceptional chemical resistance and structural integrity.

Solution: We developed a customized clear pvc suction hose with a specially formulated inner layer for enhanced chemical resistance. The clear body allowed operators to visually confirm fluid transfer and identify any potential contamination or blockages.

Outcome: The customized hoses provided reliable, leak-free performance over a sustained period, exceeding the client's expectations for chemical compatibility and service life. The transparency feature proved highly beneficial for process monitoring, enhancing operational safety and efficiency. This project showcased our capability in delivering high-performance solutions for hazardous applications.

Authoritative References and Certifications

Kebing Hose operates under a strict ISO 9001:2015 certified Quality Management System, ensuring consistency and excellence in every product. Our materials and manufacturing processes comply with international standards, including FDA regulations for specific food-grade applications, and environmental directives such as REACH and RoHS. Our long-standing relationships with industry leaders globally, coupled with over two decades of dedicated service, underscore our authoritative position in the industrial hose market.

Trustworthiness: FAQ, Lead Time, Warranty & Support

At Kebing Hose, transparency and customer satisfaction are paramount. We provide clear information on our products, processes, and support to foster enduring trust.

Frequently Asked Questions (FAQ)

- Q: What is the typical service life of your PVC suction hoses?

A: With proper handling and maintenance, our pvc suction hoses generally last between 5 to 10 years, depending on the application's severity, transferred media, and environmental conditions. Regular inspection can further extend this life.

- Q: Can these hoses handle abrasive materials?

A: Yes, our grit suction hoses are specifically designed with a high-abrasion-resistant PVC compound and robust helix reinforcement to effectively transfer sand, gravel, slurries, and other abrasive media.

- Q: Are your hoses suitable for potable water or food contact?

A: We offer specialized food-grade clear pvc suction hose options that comply with FDA regulations, making them safe for potable water and various food & beverage transfer applications.

- Q: What is the maximum vacuum rating?

A: Our PVC suction hoses are designed for full vacuum applications, typically rated at -0.08 to -0.09 MPa (equivalent to 80-90% vacuum), ensuring no collapse under strong suction.

- Q: Can I get custom lengths or specific fittings?

A: Absolutely. We offer extensive customization for lengths, diameters (e.g., pvc suction hose pipe 2 inch, 3 inch, etc.), material compounds, and pre-assembled hose with various fittings to meet your exact project requirements.

Lead Time & Fulfillment

Our standard lead time for stock items is typically 5-7 business days. For customized orders, lead times vary based on complexity and volume, usually ranging from 10 to 20 business days. We maintain a robust supply chain and efficient production schedule to ensure timely delivery, and our logistics team works to optimize shipping for both domestic and international clients, ensuring competitive pvc suction hose pipe price including delivery.

Warranty Commitments

Kebing Hose products are backed by a comprehensive 12-month warranty against manufacturing defects from the date of purchase. This commitment reflects our confidence in the quality and durability of our pvc suction hoses, provided they are used under recommended operating conditions and in accordance with established industry practices.

Dedicated Customer Support

Our expert customer support team is available to assist with product selection, technical inquiries, order tracking, and any after-sales service needs. We pride ourselves on providing prompt, knowledgeable, and reliable support to ensure optimal performance and satisfaction for all our clients.

References

- International Organization for Standardization. ISO 1307:2006 – Rubber and plastics hoses – Hose sizes, minimum and maximum inside diameters, and tolerances on cut-to-length hoses.

- Food and Drug Administration. Title 21 Code of Federal Regulations (CFR) Part 177 – Indirect Food Additives: Polymers.

- European Chemicals Agency. Registration, Evaluation, Authorisation and Restriction of Chemicals (REACH) Regulation (EC) No 1907/2006.

- European Parliament and Council of the European Union. Directive 2011/65/EU on the restriction of the use of certain hazardous substances in electrical and electronic equipment (RoHS).

- Modern Plastics Global Magazine. "Industrial Hoses Market Poised for Growth Driven by Manufacturing and Infrastructure Development." 2023.

-

PVC Suction Hoses: Flexible, Durable Fluid Transfer SolutionsNyhederAug.28,2025

-

Advanced Corrugated Pvc Hose Technology for Modern Industrial NeedsNyhederAug.22,2025

-

Premium Fire Water Hose Solutions for Global IndustriesNyhederAug.22,2025

-

Industrial Suppliers Guide to Premium Double Welding Hose SolutionsNyhederAug.22,2025

-

Premium PU Pneumatic Hose Solutions for Industrial ApplicationsNyhederAug.22,2025

-

Wholesale PVC Garden Hose China Solutions for Global BuyersNyhederAug.22,2025