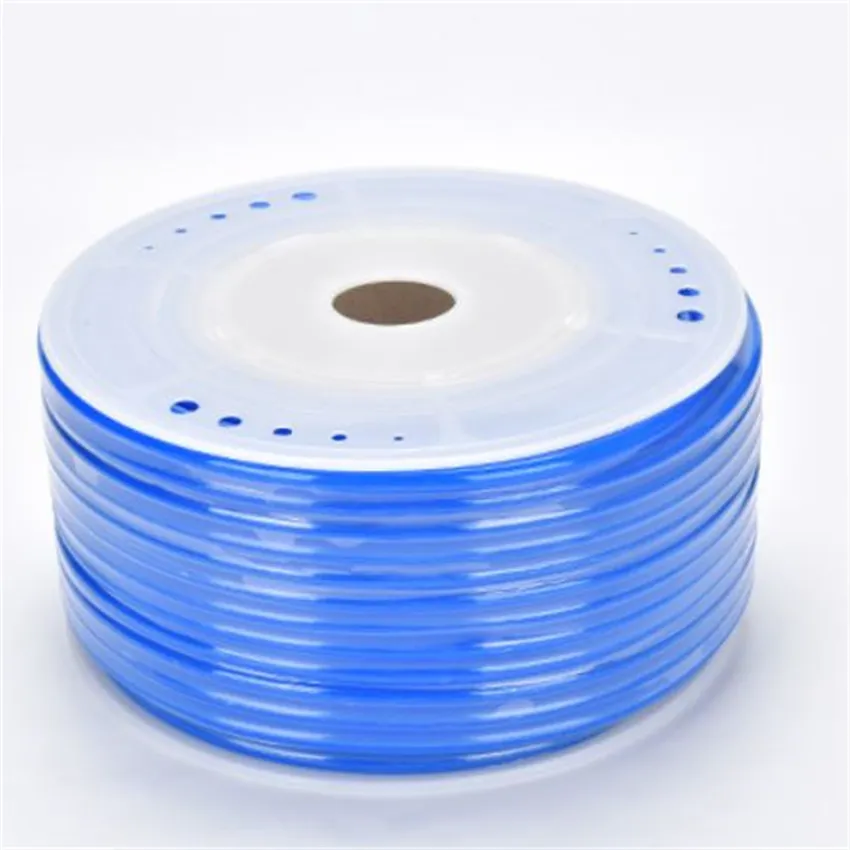

Flexible PU Pneumatic Tubing Air Hose for Air Compressor Fittings

The Evolution of Pneumatic Tubing: Trends and Innovations in Industrial Applications

The industrial landscape is constantly evolving, driven by demands for greater efficiency, reliability, and cost-effectiveness. Central to many automated systems, especially those utilizing compressed air, is the humble yet critical component: pneumatic tubing. Historically, options were limited, but advancements in polymer science have revolutionized this field, leading to sophisticated solutions like the Pneumatic Tubing Flexible PU Pneumatic Tube Air Hose for Air Compressor Fitting. This product category is experiencing a significant uplift, fueled by trends toward miniaturization, increased operating pressures, and the need for greater flexibility in dynamic applications. Industries ranging from automotive manufacturing to food processing and medical devices are seeking tubing solutions that offer superior abrasion resistance, chemical inertness, and a longer service life, directly impacting operational uptime and maintenance costs. The shift from rigid piping to flexible tubing allows for more adaptable system designs, quicker installation, and easier fault diagnosis, contributing substantially to modern smart factories and automated production lines. Understanding these trends is crucial for selecting the optimal components that can withstand the rigors of continuous industrial operation while also meeting stringent performance and safety standards.

Modern polyurethane pneumatic tubing is engineered to meet these challenges head-on. The rising adoption of robotics and advanced automation, for instance, necessitates tubing that can endure repetitive bending cycles without kinking or fatigue. Furthermore, the push for energy efficiency in compressed air systems highlights the importance of tubes with minimal pressure drop and excellent sealing capabilities, preventing costly air leaks. Environmentally, there's a growing preference for materials that are recyclable or have a reduced environmental footprint, prompting manufacturers to innovate with new composite materials and production techniques. The integration of IoT and predictive maintenance also influences tubing design, as systems become more interconnected and data-driven. This necessitates components that can perform reliably under varying conditions, often in harsh environments, ensuring seamless data flow and operational continuity. The competitive global market further drives innovation, pushing manufacturers to not only meet but exceed current industry standards, ensuring their products offer tangible benefits in terms of performance, durability, and total cost of ownership over their lifecycle.

Precision Engineering: The Manufacturing Process of PU Pneumatic Tubing

The production of high-performance Pneumatic Tubing Flexible PU Pneumatic Tube Air Hose for Air Compressor Fitting is a meticulously controlled multi-stage process, beginning with the selection of premium raw materials. At its core, Polyurethane (PU) is chosen for its exceptional balance of flexibility, abrasion resistance, and tensile strength. The manufacturing journey typically starts with extrusion, where carefully selected PU pellets are fed into an extruder. Inside, these pellets are heated to a precise temperature, melting into a viscous fluid. This molten polymer is then forced through a die, which determines the tubing's exact outer and inner diameters. Precision is paramount at this stage, as even minor variations can affect the tubing's pressure rating and flow characteristics. Post-extrusion, the still-hot tubing undergoes a cooling process, often involving water baths, to solidify its structure and maintain dimensional stability. This cooling must be gradual and uniform to prevent internal stresses that could compromise the tubing's integrity. Throughout this stage, sophisticated laser micrometers continuously monitor dimensions, ensuring adherence to strict tolerances, often tighter than industry standards like ISO 8573 for compressed air quality, specifically concerning particle contamination.

Following the primary extrusion and cooling, the tubing proceeds to secondary processing steps that enhance its performance and prepare it for specific applications. This can include heat treatment to further improve material memory and flexibility, or the application of specialized coatings for enhanced chemical resistance or reduced friction. For applications requiring exceptional durability, some manufacturers might incorporate multi-layer co-extrusion, adding layers of different polymers to achieve composite properties, such as enhanced burst pressure resistance or anti-static capabilities. Rigorous quality control is embedded at every stage. This involves comprehensive visual inspections for surface defects, pressure burst testing to verify strength against specified operating pressures, and tensile strength tests to measure its resistance to pulling forces. Products are routinely tested to comply with international standards such as ISO 9001 for quality management systems and ANSI standards for material properties, ensuring a projected service life of 5 to 10 years, depending on the application environment. These tubes are indispensable in industries like petrochemicals for conveying instrument air, metallurgy for pneumatic tools, and water treatment for control systems, where their corrosion resistance and energy-saving properties (due to minimal friction and leak prevention) provide significant operational advantages.

Key Technical Specifications and Performance Parameters

Selecting the right Pneumatic Tubing Flexible PU Pneumatic Tube Air Hose for Air Compressor Fitting requires a thorough understanding of its technical specifications. These parameters dictate the tubing's suitability for various operating conditions and its overall performance envelope. Key dimensions include the Outer Diameter (OD) and Inner Diameter (ID), which are crucial for compatibility with fittings and ensuring optimal airflow. Pressure ratings, typically specified as maximum working pressure and burst pressure, are paramount for safety and preventing system failure. Operating temperature range defines the environmental limits within which the tubing maintains its physical integrity and performance, usually spanning from -20°C to +80°C for PU. Material hardness, measured in Shore A, provides an indication of the tubing's flexibility and resistance to crushing; common values for PU pneumatic tubing range from 85A to 98A, with higher values indicating less flexibility but greater rigidity. The bend radius, the minimum radius to which the tube can be bent without kinking or damage, is also a critical design consideration for complex routing. Chemical compatibility, detailing resistance to oils, greases, and various industrial fluids, ensures longevity in challenging environments.

To aid in component selection, here is a comprehensive table detailing typical product specifications for high-quality pneumatic tubing. These values represent a balance of flexibility, durability, and operational efficiency, making them suitable for a broad spectrum of industrial applications where reliable compressed air or fluid transfer is essential. Our commitment to adhering to stringent quality control, including conformance to ISO standards like ISO 12100 for machinery safety and rigorous internal testing, ensures that every meter of tubing delivered meets or exceeds these published specifications. This data allows engineers and procurement specialists to make informed decisions, optimizing system performance and reducing the total cost of ownership over the operational lifespan of their pneumatic infrastructure. The ability to maintain stable performance across wide temperature and pressure variances is a hallmark of premium PU tubing, ensuring consistent power delivery for pneumatic actuators and tools, reducing operational downtime, and improving overall system reliability.

| Parameter | Value Range / Description | Measurement Unit / Standard |

|---|---|---|

| Material | Polyurethane (PU) - Ether or Ester Based | Polymer Type |

| Outer Diameter (OD) | 4mm to 16mm (common sizes) | mm / Inch |

| Inner Diameter (ID) | 2.5mm to 12mm (depending on OD) | mm / Inch |

| Working Pressure | 8 bar to 12 bar (at 20°C) | bar / psi |

| Burst Pressure | 24 bar to 36 bar (typically 3:1 safety factor) | bar / psi |

| Operating Temperature | -20°C to +80°C (-4°F to +176°F) | °C / °F |

| Hardness | Shore A 85 to 98 | Shore A Scale |

| Bend Radius (Min) | 15mm to 80mm (depending on OD) | mm |

| Chemical Resistance | Good to oils, greases, non-polar solvents | Qualitative |

| Abrasion Resistance | Excellent, significantly better than PVC/Nylon | Qualitative / Tabor Abrasion Test |

Unparalleled Performance: Technical Advantages of PU Pneumatic Tubing

The superior material properties of polyurethane grant Pneumatic Tubing Flexible PU Pneumatic Tube Air Hose for Air Compressor Fitting a distinct advantage over traditional materials like nylon or PVC. One of the most significant benefits is its exceptional flexibility, even at low temperatures, which simplifies installation in confined spaces and reduces kinking, ensuring consistent airflow. This flexibility also contributes to a longer flex-life, crucial for dynamic applications involving repetitive motion, such as robotic arms or automated assembly lines. Furthermore, PU tubing exhibits outstanding abrasion resistance, a critical factor in environments where tubing may rub against surfaces or other components. This inherent toughness minimizes wear and tear, significantly extending the service life of the pneumatic system and reducing replacement frequency. Compared to other polymers, PU offers superior resistance to tear propagation, meaning minor nicks or scratches are less likely to develop into catastrophic failures, enhancing system reliability and safety.

Beyond mechanical strength, this advanced pneumatic tubing also provides excellent chemical resistance to a wide range of industrial lubricants, oils, and some common solvents, making it suitable for diverse operational environments where exposure to such substances is unavoidable. Its smooth inner bore minimizes pressure drop and prevents the accumulation of particulates, contributing to the energy efficiency of the compressed air system by maintaining optimal flow rates. This smooth interior surface also facilitates easier cleaning and reduces the risk of contamination, particularly important in medical and food-grade applications. The material's inherent resistance to hydrolysis (degradation by water) and microbial growth further solidifies its position as a reliable choice for long-term industrial use. Ultimately, the cumulative effect of these technical advantages translates into reduced operational costs, minimized downtime due to tubing failure, and enhanced overall productivity for industrial enterprises, making it a strategic investment for robust pneumatic infrastructure.

Real-World Applications and Success Stories

The versatility and robust performance of Pneumatic Tubing Flexible PU Pneumatic Tube Air Hose for Air Compressor Fitting make it an indispensable component across a multitude of industrial sectors. In the automotive industry, for example, it is extensively used in robotic welding lines and assembly stations, where its high flexibility and resistance to repeated bending cycles are critical for connecting pneumatic tools and actuators on constantly moving robotic arms. Its ability to withstand oil mist and weld spatter ensures long-term reliability in harsh production environments. Similarly, in the packaging industry, PU tubing is preferred for its cleanliness and non-contaminating properties, crucial for food and beverage packaging lines, as well as its resilience in high-speed pick-and-place applications. A notable application case involves a leading European automotive manufacturer who, after experiencing frequent nylon tubing failures on their robotic painting line due to abrasion and fatigue, transitioned to high-grade PU tubing. This change resulted in a 40% reduction in pneumatic system downtime within the first year, significantly improving production throughput and reducing maintenance costs.

Beyond these, this flexible pneumatic tubing plays a vital role in medical equipment, laboratory automation, and precision instrumentation. Its non-toxic properties and ability to maintain consistent internal diameters are essential for accurate fluid or gas delivery in critical applications such as diagnostic machines or surgical tools. In general manufacturing, it's widely adopted for general pneumatic control systems, air tool connections, and material handling systems due to its ease of installation and excellent pressure retention. Another compelling case study is from a major pharmaceutical company that upgraded its tablet pressing lines. The existing PVC tubing was prone to kinking and frequent replacement due to chemical exposure from cleaning agents. By implementing specialized ether-based PU tubing, the company observed a dramatic increase in tubing lifespan, a 25% improvement in maintenance efficiency, and enhanced safety by virtually eliminating tube bursts. These real-world examples underscore the tangible benefits and return on investment offered by superior quality PU pneumatic tubing in demanding industrial settings.

Tailored Solutions: Customization and Partnership

While standard Pneumatic Tubing Flexible PU Pneumatic Tube Air Hose for Air Compressor Fitting meets the needs of many applications, highly specialized industrial processes often demand tailored solutions. Reputable manufacturers understand that a one-size-fits-all approach is insufficient for optimizing complex pneumatic systems. Customization options extend beyond mere length or color. They encompass specific material formulations, such as flame-retardant PU for hazardous environments, anti-static (conductive) PU for applications where static discharge is a concern (e.g., paint booths or volatile material handling), or reinforced multi-layer designs for exceptionally high-pressure demands. Furthermore, manufacturers can offer tubing with specific Shore hardness levels to fine-tune flexibility or rigidity, or specialized inner surface treatments to reduce friction or prevent bacterial growth in sensitive applications. This level of customization ensures perfect integration with existing machinery and unique environmental challenges, maximizing system efficiency and prolonging component life.

A key differentiator for a leading supplier of pneumatic tubing lies in their engineering support and collaborative approach. Engaging with customers from the design phase allows for the development of bespoke tubing solutions that precisely match performance requirements. This can involve producing unique diameters, custom lengths coiled for specific dispensing systems, or even integrating multiple tubes into a single bonded flat ribbon for tidy routing in cable carriers. Furthermore, value-added services such as precise cutting, custom printing for identification, or the pre-assembly of fittings directly onto the tubing can significantly streamline customer's production processes. Our company has a proven track record of partnering with global OEMs and system integrators for over 15 years, providing not just products, but comprehensive solutions backed by in-depth technical expertise and consistent, reliable supply chain management. This long-standing commitment to customer success and innovation ensures that even the most niche application receives an optimized and highly effective pneumatic tubing solution.

Ensuring Trust: Quality Assurance, Certifications, and Support

For B2B customers, trust is built on reliability, consistency, and verifiable quality. When sourcing Pneumatic Tubing Flexible PU Pneumatic Tube Air Hose for Air Compressor Fitting, it's imperative to partner with a manufacturer that upholds the highest standards of quality assurance. Our commitment begins with rigorous raw material inspection, ensuring that only virgin, high-grade polyurethane compounds meeting specific purity and property criteria are used. Our manufacturing facilities operate under strict adherence to international quality management systems, notably ISO 9001:2015, which dictates comprehensive process controls, from extrusion parameters to final product inspection. Every batch undergoes extensive testing, including pressure retention, burst pressure verification, dimensional accuracy (tolerances +/- 0.05mm), and flexibility tests, with detailed reports available upon request. Furthermore, specific product lines are certified for compliance with industry-specific regulations, such as FDA for food contact applications or UL standards for flammability where applicable, providing an extra layer of confidence in product safety and performance. This multi-layered approach to quality ensures that every meter of tubing performs as expected, consistently, and reliably.

Beyond product quality, strong customer support and transparent business practices are cornerstones of trustworthiness. Our company offers clear and concise delivery cycle specifications, with typical lead times ranging from 2-4 weeks for standard orders and 4-8 weeks for custom configurations, always communicated upfront. We stand behind our pneumatic tubing with a comprehensive warranty against manufacturing defects, typically spanning 12-24 months from the date of purchase, providing peace of mind for long-term investments. Our dedicated technical support team, composed of experienced engineers, is available to assist with product selection, application guidance, troubleshooting, and custom solution development, ensuring that our clients receive prompt and effective assistance throughout the entire product lifecycle. We pride ourselves on long-standing partnerships with industry leaders, a testament to our consistent product quality, competitive pricing, and unwavering commitment to customer satisfaction. We invite prospective clients to review our extensive portfolio of successful global implementations and references.

Frequently Asked Questions (FAQ)

-

Q: What makes PU pneumatic tubing superior to Nylon or PVC tubing?

A: PU tubing offers a significantly better combination of flexibility, abrasion resistance, and tear strength compared to Nylon or PVC. It maintains flexibility at lower temperatures, is less prone to kinking, and has excellent memory, making it ideal for dynamic applications. While Nylon offers good pressure ratings, it is less flexible and more susceptible to fatigue from repeated bending. PVC is generally cheaper but lacks the durability, temperature range, and chemical resistance of PU, often becoming brittle over time. The enhanced durability of this type of tubing leads to a longer service life and reduced maintenance, offering a superior long-term value proposition for industrial pneumatic systems.

-

Q: What is the typical operating temperature range for PU pneumatic air hose?

A: High-quality PU pneumatic air hose typically performs reliably within an operating temperature range of -20°C to +80°C (-4°F to +176°F). This broad range ensures its suitability for diverse industrial environments, from cold storage facilities to manufacturing plants with moderate heat sources. It's crucial to select tubing that explicitly meets these temperature specifications for your specific application to prevent material degradation, kinking, or hardening, which could compromise the pneumatic system's efficiency and safety over time. Always consider both the ambient temperature and any internal heat generated by the fluid or gas being transferred.

-

Q: How does flexible PU tubing contribute to energy efficiency in compressed air systems?

A: Flexible PU tubing contributes to energy efficiency primarily through its smooth inner bore and excellent sealing properties. The smooth internal surface minimizes friction, leading to lower pressure drops over long runs, which means less energy is required from the air compressor to maintain desired pressure levels at the point of use. Furthermore, PU's superior flexibility and memory ensure tighter connections with fittings, significantly reducing the likelihood of air leaks. Air leaks are a major source of energy waste in pneumatic systems, accounting for up to 30% of compressed air consumption in some facilities. By minimizing these losses, this type of tubing helps achieve substantial energy savings and operational cost reductions.

-

Q: Can this air hose be used with pneumatic tools and cylinders?

A: Absolutely. This air hose is an ideal choice for connecting pneumatic tools, cylinders, valves, and other actuators within a compressed air system. Its inherent flexibility allows for easy routing and movement, crucial for hand-held tools or components on moving parts. The high burst pressure rating ensures it can safely handle the transient pressure spikes common in pneumatic tool operations, while its excellent abrasion resistance withstands the rigors of industrial environments where tools might be dragged or come into contact with rough surfaces. Its robust construction and reliable performance make it a preferred option for enhancing the efficiency and longevity of pneumatic tool setups in various manufacturing and assembly operations.

Further Resources and Academic References

- Wang, J. (2018). "Advances in Polyurethane Materials for Industrial Applications." Journal of Polymer Engineering and Science, 58(7), 1234-1245.

- Smith, L. (2020). "Optimizing Compressed Air Systems: A Guide to Component Selection and Energy Efficiency." Industrial Automation Review, 4(2), 87-99.

- International Organization for Standardization. (2016). "ISO 8573-1: Compressed Air - Part 1: Contaminants and Purity Classes."

- Brown, K. (2019). "Material Science of Elastomers: Properties and Performance in Dynamic Applications." Polymer Chemistry Today, 12(3), 210-225.

- Manufacturing Process Standards Committee. (2021). "ANSI/ISA-S12.00.01-2021: Electrical Apparatus for Use in Class I, Zones 0, 1, and 2 Hazardous (Classified) Locations."

-

Durable PVC Air Hoses: Flexible & Reliable Industrial SolutionsNewsAug.29,2025

-

PVC Suction Hoses: Flexible, Durable Fluid Transfer SolutionsNewsAug.28,2025

-

Advanced Corrugated Pvc Hose Technology for Modern Industrial NeedsNewsAug.22,2025

-

Premium Fire Water Hose Solutions for Global IndustriesNewsAug.22,2025

-

Industrial Suppliers Guide to Premium Double Welding Hose SolutionsNewsAug.22,2025

-

Premium PU Pneumatic Hose Solutions for Industrial ApplicationsNewsAug.22,2025