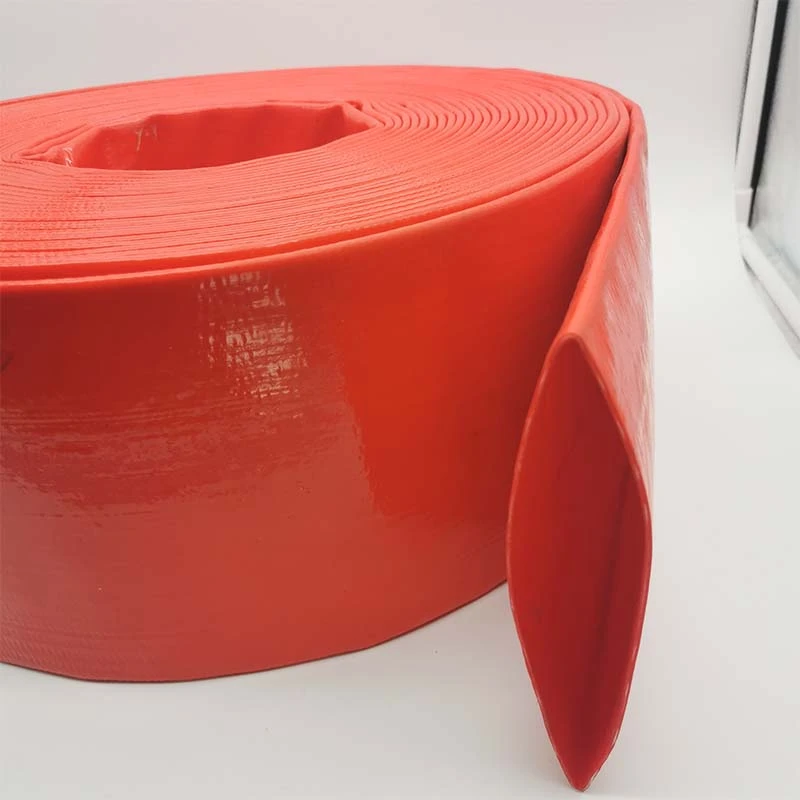

fiber pvc

The Role of Fiber PVC in Modern Construction and Manufacturing

Fiber PVC, or fiber-reinforced polyvinyl chloride, has emerged as a significant material in various industries, particularly in construction and manufacturing. This innovative composite combines the durability of PVC with the strength and lightweight properties of fibers, making it a versatile and effective choice for many applications.

Understanding Fiber PVC

At its core, Fiber PVC is a type of synthetic polymer that integrates fiber materials into the traditional PVC structure. These fibers, which can be made from glass, carbon, or natural sources, enhance the mechanical properties of PVC, improving its tensile strength and impact resistance. This combination results in a material that not only maintains the inherent advantages of PVC—such as corrosion resistance and low maintenance—but also offers enhanced structural performance.

Applications in Construction

In the construction industry, Fiber PVC is increasingly utilized for various products, including pipes, panels, and siding. One of the primary advantages of using Fiber PVC is its excellent load-bearing capacity, which makes it suitable for applications where weight reduction is crucial without compromising strength. For instance, Fiber PVC pipes are lighter than traditional materials but can withstand high pressures, making them ideal for plumbing and drainage systems.

Moreover, the use of Fiber PVC in building facades offers enhanced aesthetic appeal alongside strong weather resistance. These materials can be manufactured in various colors and textures, allowing for greater design flexibility. They are also more resistant to fading and cracking than standard PVC, ensuring longevity and reduced need for repairs.

Benefits in Manufacturing

fiber pvc

The manufacturing sector has also benefited from the adoption of Fiber PVC. Its lightweight nature reduces shipping costs and handling labor, making it economically advantageous for businesses. Furthermore, the material's durability leads to longer product lifespans, ultimately resulting in cost savings over time.

Fiber PVC is also utilized in the production of various goods, from automotive parts to consumer products. Its versatility allows manufacturers to explore new designs and applications that were not feasible with traditional materials. As industries trend towards sustainability, Fiber PVC's recyclability offers an added environmental benefit, aligning with green manufacturing practices.

Challenges and Considerations

Despite its advantages, the adoption of Fiber PVC is not without challenges. Manufacturing processes may require adjustments to accommodate the behavior of the fiber-reinforced material. Additionally, the initial cost of Fiber PVC can be higher than that of conventional materials, which might deter some companies, especially smaller enterprises with limited budgets.

Another consideration is the need for proper disposal methods at the end of the product's lifecycle. While Fiber PVC is recyclable, it is essential for manufacturers to establish return programs or recycling initiatives to manage waste effectively and promote sustainability.

Conclusion

In summary, Fiber PVC represents a significant advancement in materials science, particularly for construction and manufacturing. Its unique combination of strength, lightweight, and durability opens up new possibilities for engineers and designers alike. As industries continue to value sustainability and efficiency, the role of Fiber PVC is likely to expand, paving the way for innovative solutions that meet the demands of modern society. By overcoming current challenges and enhancing recycling processes, Fiber PVC has the potential to contribute positively to various sectors in the years to come.

-

Unrivaled Performance and Applications of PU Pneumatic Hoses and TubesNewsJun.11,2025

-

The Transparent World of Industrial Tubing and Hosing SolutionsNewsJun.11,2025

-

The Intricate World of Pneumatic Conduits: Tubes and HosesNewsJun.11,2025

-

The Dynamic Landscape of Pneumatic Conduits: Unraveling Key ComponentsNewsJun.11,2025

-

The Diverse Applications and Significance of Transparent PVC TubingNewsJun.11,2025

-

High - Pressure Pneumatic Tubing and Systems: An In - Depth LookNewsJun.11,2025