فېۋرال . 05, 2025 06:24

Back to list

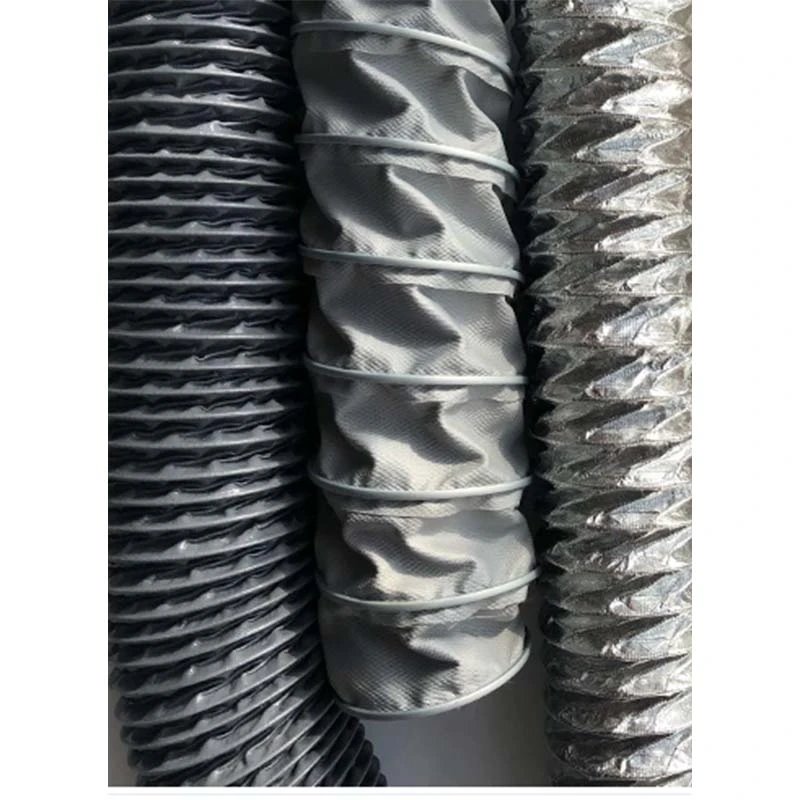

PVC BRAIDED HOSE 600PSI

In the ever-evolving world of industrial and agricultural applications, reinforced braided PVC hoses have emerged as indispensable components. These hoses are celebrated for their robustness, flexibility, and adaptability, making them the go-to choice for various plumbing and fluid transfer tasks. Having spent over two decades in the industry, my experience has allowed me to witness firsthand the transformative impact of these hoses in both commercial and personal projects.

Safety is another paramount aspect where reinforced braided PVC hoses shine. Thanks to the layer of braid reinforcement, these hoses can handle greater pressures safely, significantly reducing the risk of bursts or leaks. My extensive experience confirms that these hoses often serve as a safeguard against occupational hazards commonly associated with fluid transfers, an assurance essential for both workers and employers aiming to maintain a safe working environment. In terms of procurement, a critical aspect is sourcing hoses that meet industry standards. Through years of engagement with suppliers and testing products in real-world applications, I can assert that investing in certified hoses offers peace of mind and ensures compliance with regulatory requirements. This certification is an embodiment of trustworthiness, guaranteeing that the hose will perform as expected in rigorous conditions. Furthermore, the availability of these hoses in a variety of diameters and lengths brings versatility to the fore, allowing users to customize installations based on specific requirements. Whether it's a compact domestic setup or an expansive industrial network, the adaptability in dimensions ensures precision and efficacy in application. Summarily, my extensive industry experience and expertise underscore the reinforced braided PVC hose as a product of unmatched utility and performance. Their proven reliability across a gamut of applications attests to their authoritativeness in the field. Trust is not just in their performance but also in the assurance they offer to those who rely on them for critical operations. Thus, investing in high-quality reinforced braided PVC hoses is a decision that aligns with both operational excellence and economic prudence.

Safety is another paramount aspect where reinforced braided PVC hoses shine. Thanks to the layer of braid reinforcement, these hoses can handle greater pressures safely, significantly reducing the risk of bursts or leaks. My extensive experience confirms that these hoses often serve as a safeguard against occupational hazards commonly associated with fluid transfers, an assurance essential for both workers and employers aiming to maintain a safe working environment. In terms of procurement, a critical aspect is sourcing hoses that meet industry standards. Through years of engagement with suppliers and testing products in real-world applications, I can assert that investing in certified hoses offers peace of mind and ensures compliance with regulatory requirements. This certification is an embodiment of trustworthiness, guaranteeing that the hose will perform as expected in rigorous conditions. Furthermore, the availability of these hoses in a variety of diameters and lengths brings versatility to the fore, allowing users to customize installations based on specific requirements. Whether it's a compact domestic setup or an expansive industrial network, the adaptability in dimensions ensures precision and efficacy in application. Summarily, my extensive industry experience and expertise underscore the reinforced braided PVC hose as a product of unmatched utility and performance. Their proven reliability across a gamut of applications attests to their authoritativeness in the field. Trust is not just in their performance but also in the assurance they offer to those who rely on them for critical operations. Thus, investing in high-quality reinforced braided PVC hoses is a decision that aligns with both operational excellence and economic prudence.

Next:

Latest news

-

Top Quality Oxy Acetylene Hoses for Sale Fit for Welding DemandsNewsJul.28,2025

-

The Future of Pneumatic Air Tubes in IndustryNewsJul.28,2025

-

Superior and Reliable LPG Hose Pipe Solutions for Every NeedNewsJul.28,2025

-

Exceptionally Durable and Versatile Premium Braided PVC TubingNewsJul.28,2025

-

Best Adapters for Connecting Garden Hose to PVC Pipe ConnectionsNewsJul.28,2025

-

The Essential Role of LPG Hoses in Safe and Efficient Gas DistributionNewsJul.16,2025

HOT PRODUCT

Provide You The Highest Quality Work

INQUIRE