يانۋار . 20, 2025 11:31

Back to list

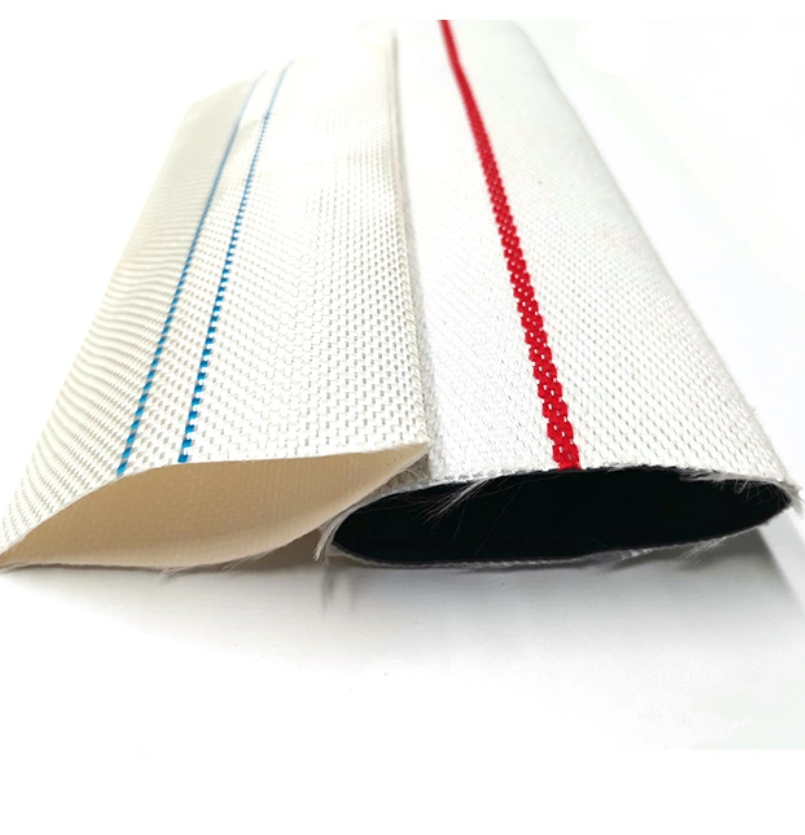

hose pvc tetoron reinforced

The modern industrial landscape has seen an unprecedented transformation in material science, especially in the domain of hose production. Among the innovations, PVC Tetoron Reinforced Hose stands out for its exceptional capabilities and practical applications. The unique construction of this hose combines flexibility, strength, and durability, making it an invaluable component across a multitude of industries.

Authoritativeness in this space is evidenced by industry standards and certifications that these hoses often fulfill. Manufacturers who offer PVC Tetoron reinforced hoses typically adhere to rigorous quality controls and safety regulations, ensuring that their products can perform under rigorous conditions. Recognized certifications such as ISO and other industry-specific validations provide customers with the assurance that they are investing in a product that meets the highest global standards of safety and reliability. Trustworthiness in the PVC Tetoron reinforced hose market is cultivated through proven field performance and customer testimonials. Many companies provide detailed case studies and field reports that highlight the successes achieved by using these hoses. The trustworthy reputation of suppliers is built over time as customers experience seamless operations, underscoring the reliability and durability promised by manufacturers. In fulfilling stringent requirements across sectors such as manufacturing, shipping, and agriculture, the PVC Tetoron reinforced hose exemplifies the synergy between material science and practical applications. These hoses are not just a commodity; they are engineered solutions designed to meet specific industry challenges and optimize production processes. As industries continue to evolve, so too will the technology and materials used in hose manufacturing, leading to even more sophisticated solutions in the future. When choosing a PVC Tetoron reinforced hose, businesses should consider comprehensive product data and consult with experts to ensure they select the right specifications for their needs. By doing so, they invest not just in a product but in a solution that enhances efficiency, safety, and productivity in their operations. With a focus on quality engineering, these hoses maintain a pivotal role in supporting the infrastructural needs of contemporary industries.

Authoritativeness in this space is evidenced by industry standards and certifications that these hoses often fulfill. Manufacturers who offer PVC Tetoron reinforced hoses typically adhere to rigorous quality controls and safety regulations, ensuring that their products can perform under rigorous conditions. Recognized certifications such as ISO and other industry-specific validations provide customers with the assurance that they are investing in a product that meets the highest global standards of safety and reliability. Trustworthiness in the PVC Tetoron reinforced hose market is cultivated through proven field performance and customer testimonials. Many companies provide detailed case studies and field reports that highlight the successes achieved by using these hoses. The trustworthy reputation of suppliers is built over time as customers experience seamless operations, underscoring the reliability and durability promised by manufacturers. In fulfilling stringent requirements across sectors such as manufacturing, shipping, and agriculture, the PVC Tetoron reinforced hose exemplifies the synergy between material science and practical applications. These hoses are not just a commodity; they are engineered solutions designed to meet specific industry challenges and optimize production processes. As industries continue to evolve, so too will the technology and materials used in hose manufacturing, leading to even more sophisticated solutions in the future. When choosing a PVC Tetoron reinforced hose, businesses should consider comprehensive product data and consult with experts to ensure they select the right specifications for their needs. By doing so, they invest not just in a product but in a solution that enhances efficiency, safety, and productivity in their operations. With a focus on quality engineering, these hoses maintain a pivotal role in supporting the infrastructural needs of contemporary industries.

Latest news

-

Top Quality Oxy Acetylene Hoses for Sale Fit for Welding DemandsNewsJul.28,2025

-

The Future of Pneumatic Air Tubes in IndustryNewsJul.28,2025

-

Superior and Reliable LPG Hose Pipe Solutions for Every NeedNewsJul.28,2025

-

Exceptionally Durable and Versatile Premium Braided PVC TubingNewsJul.28,2025

-

Best Adapters for Connecting Garden Hose to PVC Pipe ConnectionsNewsJul.28,2025

-

The Essential Role of LPG Hoses in Safe and Efficient Gas DistributionNewsJul.16,2025

HOT PRODUCT

Provide You The Highest Quality Work

INQUIRE