Understanding the Uses and Safety of Oxygen and Acetylene Hoses in Welding Applications

Understanding Oxygen and Acetylene Hoses Essential Components for Welding

In the realm of welding, understanding the tools and components necessary for safe and effective operations is paramount. Among these tools, oxygen and acetylene hoses are crucial for delivering gases used in the oxy-fuel welding and cutting processes. These hoses are not just ordinary pipes; they are specifically engineered to handle the high pressures and temperatures involved in welding applications.

The Basics of Oxy-Acetylene Welding

Oxy-acetylene welding is a process that utilizes a flame produced by burning acetylene gas in the presence of oxygen. This method allows for precise control over the heat output and is widely used for welding metals, cutting materials, and repairing components in various industries. The key to this process lies in the hoses that transport the gases from their respective cylinders to the welding torch.

Composition and Design of the Hoses

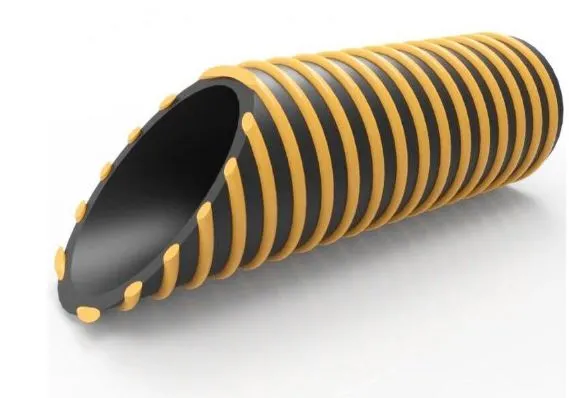

Oxygen hoses are typically color-coded green, while acetylene hoses are red. This differentiation is crucial, as using the wrong hose can lead to disastrous consequences. The hoses are made from rubber or thermoplastic materials that are designed to withstand the pressures of gas flow and resist various environmental factors. They feature reinforced layers to prevent bursting and are capable of handling temperatures of up to 2000°F (1093°C) when in use.

Moreover, the fittings at the end of the hoses are designed to ensure a secure connection to the gas cylinders and the welding torch. These connections must be leak-proof to avoid the risk of flammable gas escape, which could lead to fire or explosion hazards.

Safety Considerations

oxygen & acetylene hose

Working with oxygen and acetylene hoses comes with inherent risks. It is essential to ensure that hoses are inspected regularly for wear, cracks, or damage. Any damaged hose should be replaced immediately to prevent accidents. Additionally, hoses must never be kinked or twisted, as this can lead to structural failure and gas leakage.

When setting up for welding, it's critical to ensure that the oxygen and acetylene hoses are kept separate at all times. This separation prevents the possibility of cross-contamination or unintended ignition, which could lead to dangerous fire hazards. Proper storage is also important; hoses should be coiled properly and kept in a dry, cool place when not in use.

Proper Maintenance and Storage

To prolong the life of your oxygen and acetylene hoses, regular maintenance is vital. Hoses should be cleaned and inspected before each use, and the connections should be greased to ensure easy attachment and detachment from equipment. Proper storage also involves keeping them elevated off the ground to avoid damage from foot traffic or equipment.

In addition, hoses should be marked to indicate their intended use and status. Using tags or color-coded labels can help prevent accidents, ensuring that operators are aware of the specific functions of each hose.

Conclusion

Oxygen and acetylene hoses are indispensable for safe and effective oxy-fuel welding. Understanding their construction, maintaining them properly, and adhering to safety protocols can significantly reduce the risks associated with welding operations. By recognizing the importance of these hoses and implementing best practices, welders can ensure their work environment remains safe while achieving high-quality results in their welding tasks. Whether for industrial purposes or small-scale repairs, the reliability of these hoses is unmatched, making them a foundational element in the world of welding.

-

Top Quality Oxy Acetylene Hoses for Sale Fit for Welding DemandsNewsJul.28,2025

-

The Future of Pneumatic Air Tubes in IndustryNewsJul.28,2025

-

Superior and Reliable LPG Hose Pipe Solutions for Every NeedNewsJul.28,2025

-

Exceptionally Durable and Versatile Premium Braided PVC TubingNewsJul.28,2025

-

Best Adapters for Connecting Garden Hose to PVC Pipe ConnectionsNewsJul.28,2025

-

The Essential Role of LPG Hoses in Safe and Efficient Gas DistributionNewsJul.16,2025