Comparison of Braided Hose and Standard Hose Performance and Applications

Braided Hose vs. Standard Hose Understanding the Differences

When it comes to selecting the right hose for your application, understanding the distinctions between braided hoses and standard hoses can be crucial. The choice between the two can greatly impact performance, durability, and safety in various settings, from industrial workspaces to DIY projects at home.

What is a Braided Hose?

A braided hose consists of a flexible tube encased in a layer of braiding, usually made from materials like stainless steel or synthetic fibers. This additional layer provides enhanced strength, flexibility, and resistance to pressure. Braided hoses are commonly used in applications that involve high pressure, heat, or exposure to chemicals, making them ideal for automotive, hydraulic, and pneumatic systems.

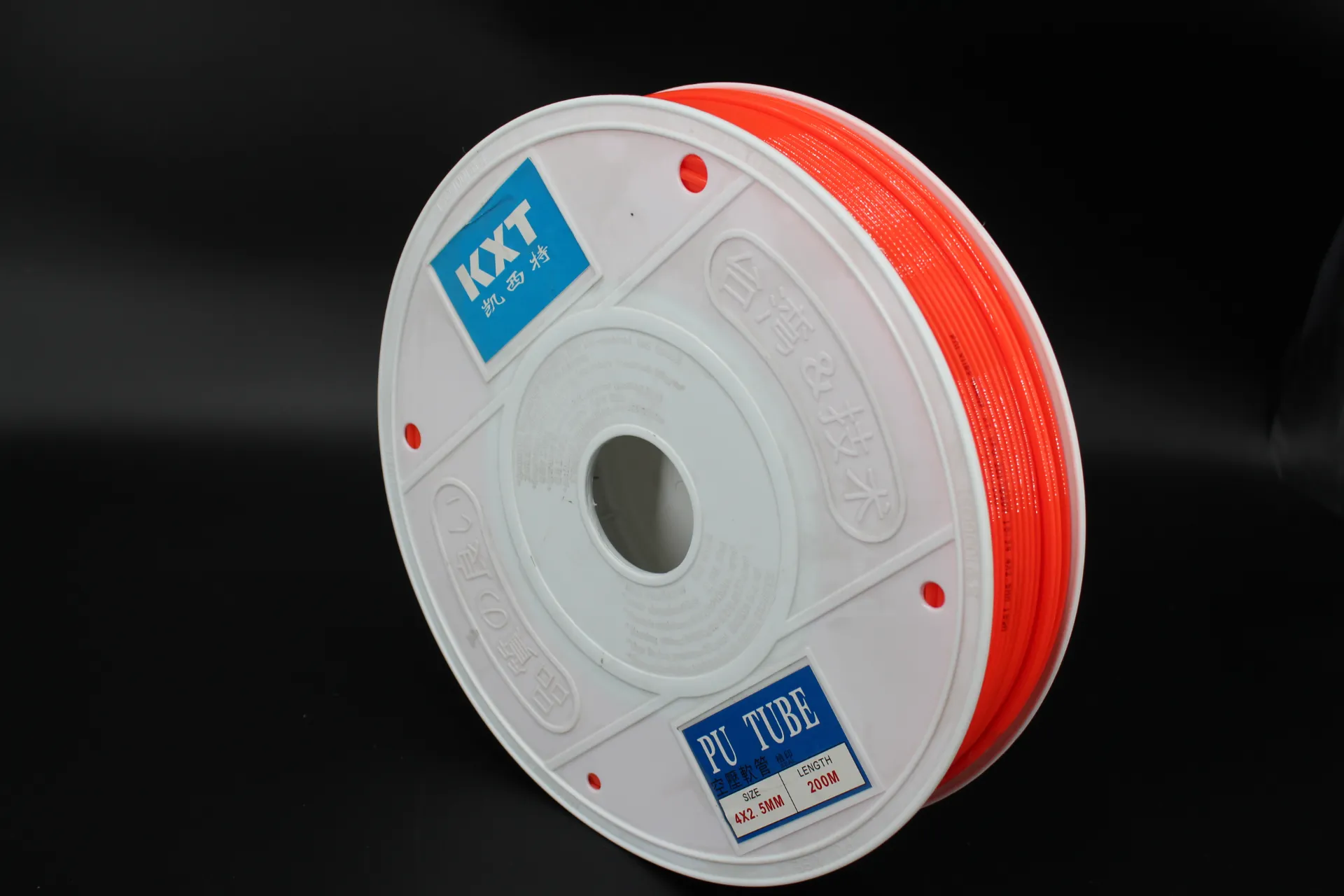

What is a Standard Hose?

On the other hand, a standard hose typically has a simpler construction, often made from rubber or plastic. Standard hoses are designed for general purposes such as gardening, watering, or low-pressure applications. While they can be durable, they lack the additional reinforcement found in braided hoses, making them less suitable for high-stress environments.

Key Differences

1. Construction and Materials The primary difference lies in their construction. Braided hoses utilize an outer layer of braided material that provides additional strength and flexibility. Standard hoses generally consist of a single or multilayer tube without this reinforcement.

2. Pressure Resistance Braided hoses are engineered to withstand significantly higher pressures. This makes them ideal for applications that involve hydraulic fluid transfer, where pressure fluctuations can be extreme. Standard hoses, while sufficient for light-duty tasks, can burst or deform under high pressure.

braided hose vs standard hose

3. Temperature Tolerance Braided hoses also tend to have a higher temperature tolerance. They can operate efficiently in environments with extreme temperatures, both hot and cold, while standard hoses may degrade or become brittle when subjected to such conditions.

4. Flexibility and Handling Braided hoses are often more flexible due to their construction, allowing for easier maneuvering in tight spaces. Standard hoses can be stiffer and more difficult to handle, especially in cold weather.

5. Cost Generally speaking, standard hoses are less expensive than braided hoses due to their simpler construction. However, when considering the longevity and performance under demanding conditions, braided hoses may provide better value over time.

Which Should You Choose?

The choice between a braided hose and a standard hose depends largely on the specific requirements of your application. If you need durability, high-pressure resistance, and temperature stability, a braided hose is the way to go. These hoses provide added safety and reliability that can be critical in many industrial or automotive scenarios.

Conversely, if your needs are more general and do not involve high pressure or extreme conditions, a standard hose may be sufficient and cost-effective for your situation. They can be ideal for tasks such as watering plants or washing vehicles.

Conclusion

In conclusion, understanding the differences between braided and standard hoses allows for informed decision-making based on the requirements of your specific project or application. By assessing factors like pressure, temperature, flexibility, and cost, users can select the most suitable hose, ensuring efficiency and safety in their endeavors.

-

Unrivaled Performance and Applications of PU Pneumatic Hoses and TubesNewsJun.11,2025

-

The Transparent World of Industrial Tubing and Hosing SolutionsNewsJun.11,2025

-

The Intricate World of Pneumatic Conduits: Tubes and HosesNewsJun.11,2025

-

The Dynamic Landscape of Pneumatic Conduits: Unraveling Key ComponentsNewsJun.11,2025

-

The Diverse Applications and Significance of Transparent PVC TubingNewsJun.11,2025

-

High - Pressure Pneumatic Tubing and Systems: An In - Depth LookNewsJun.11,2025