jul . 03, 2024 03:00

Back to list

Oxygen and acetylene hoses available for purchase at affordable prices.

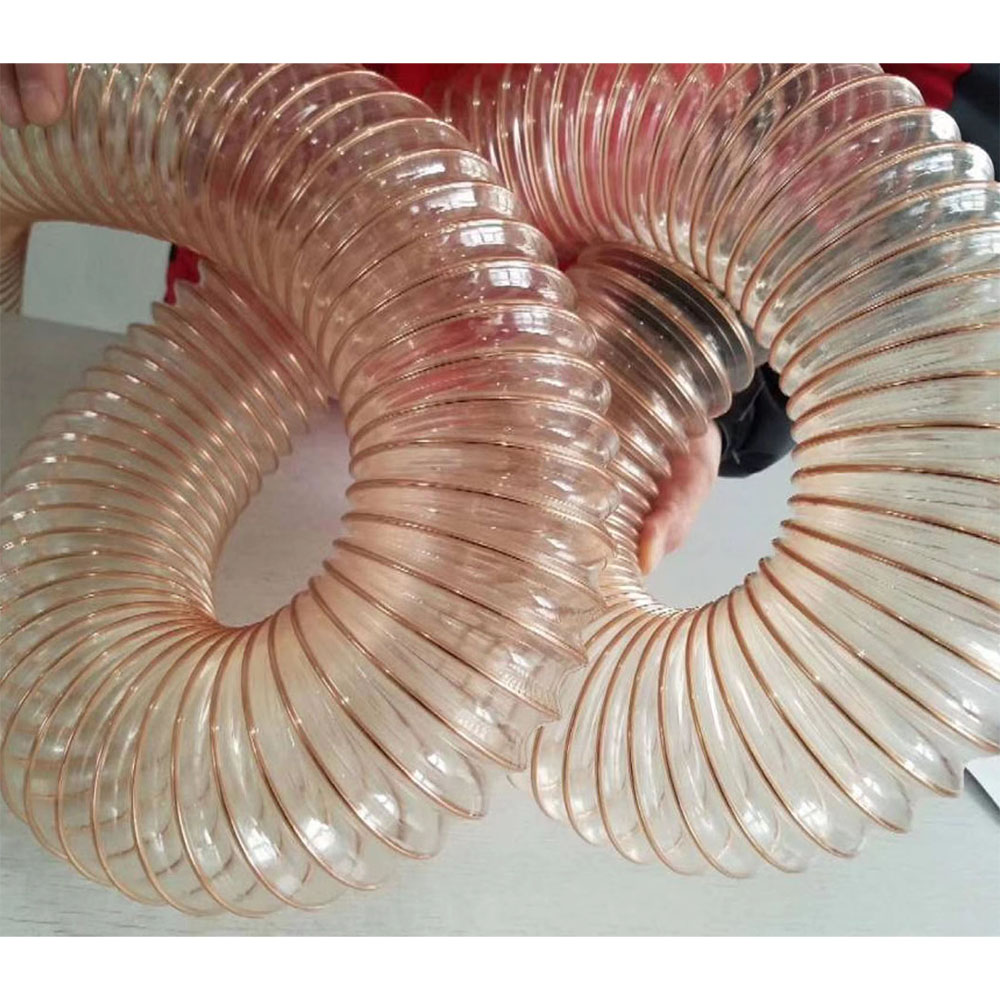

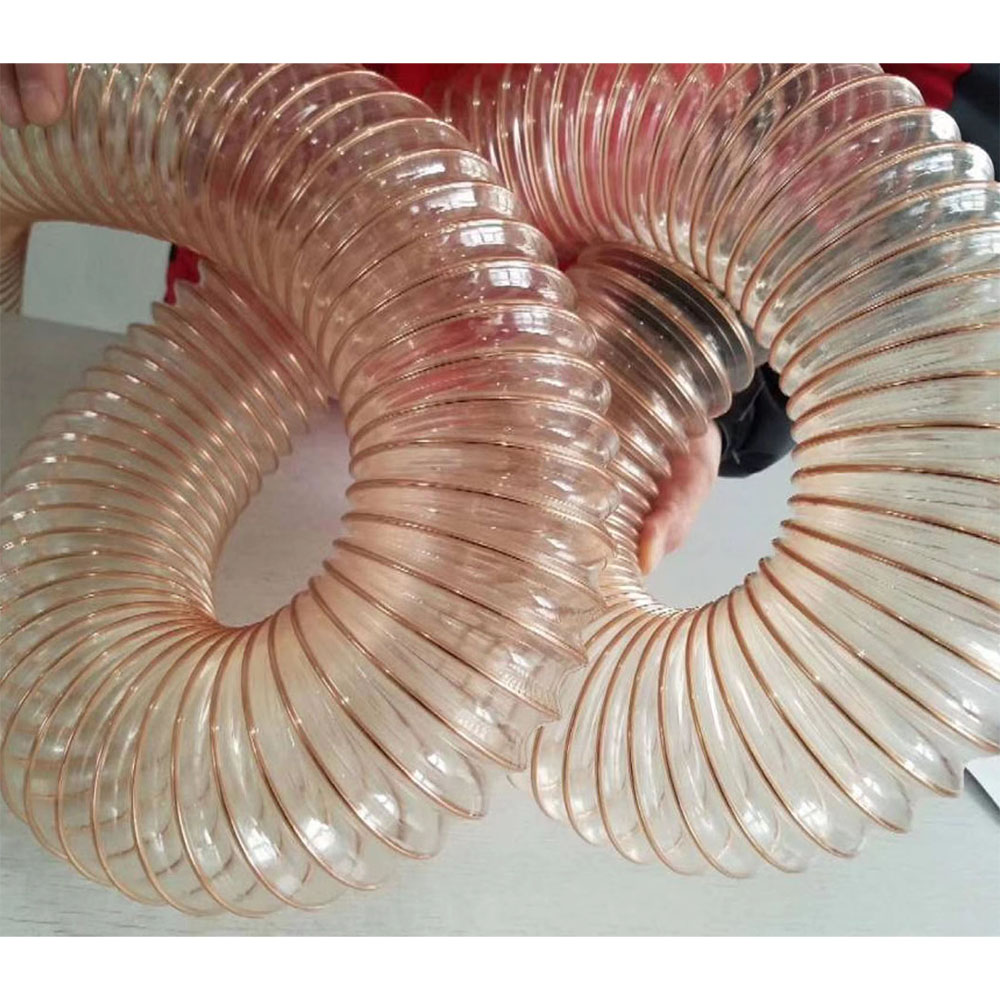

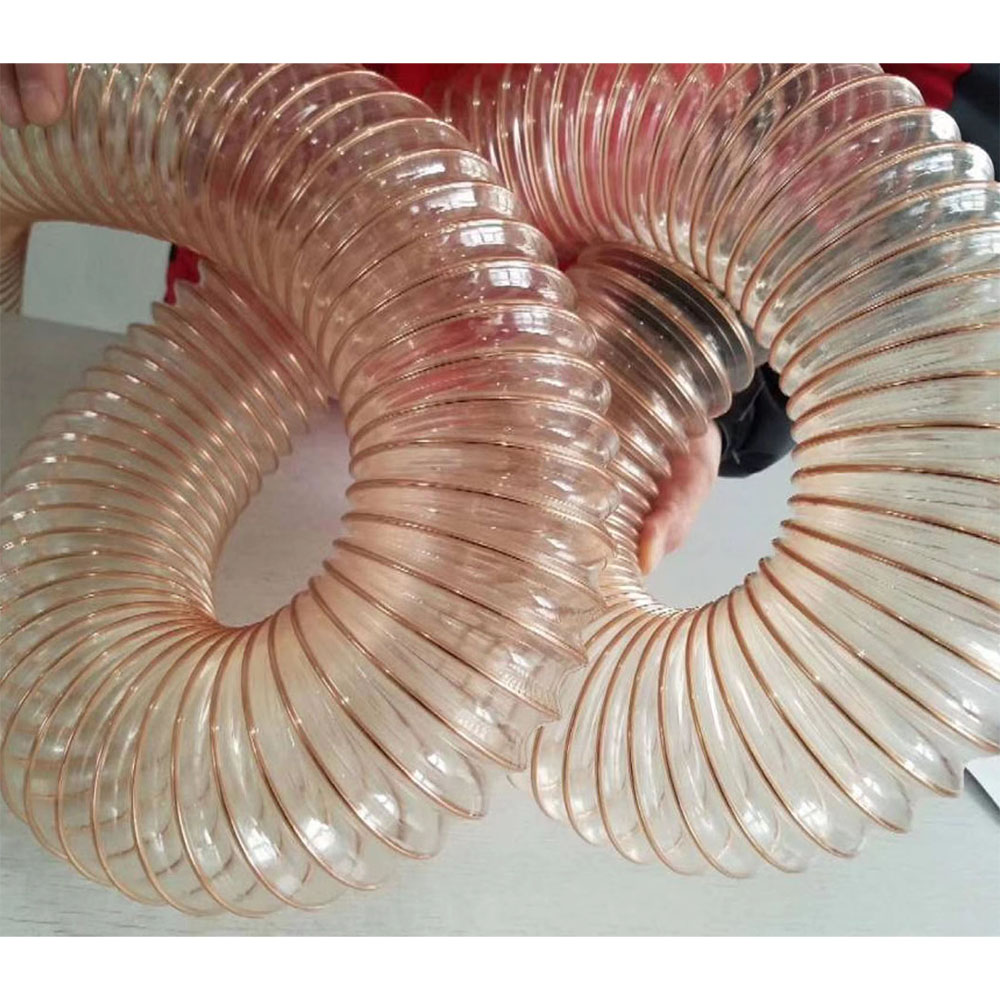

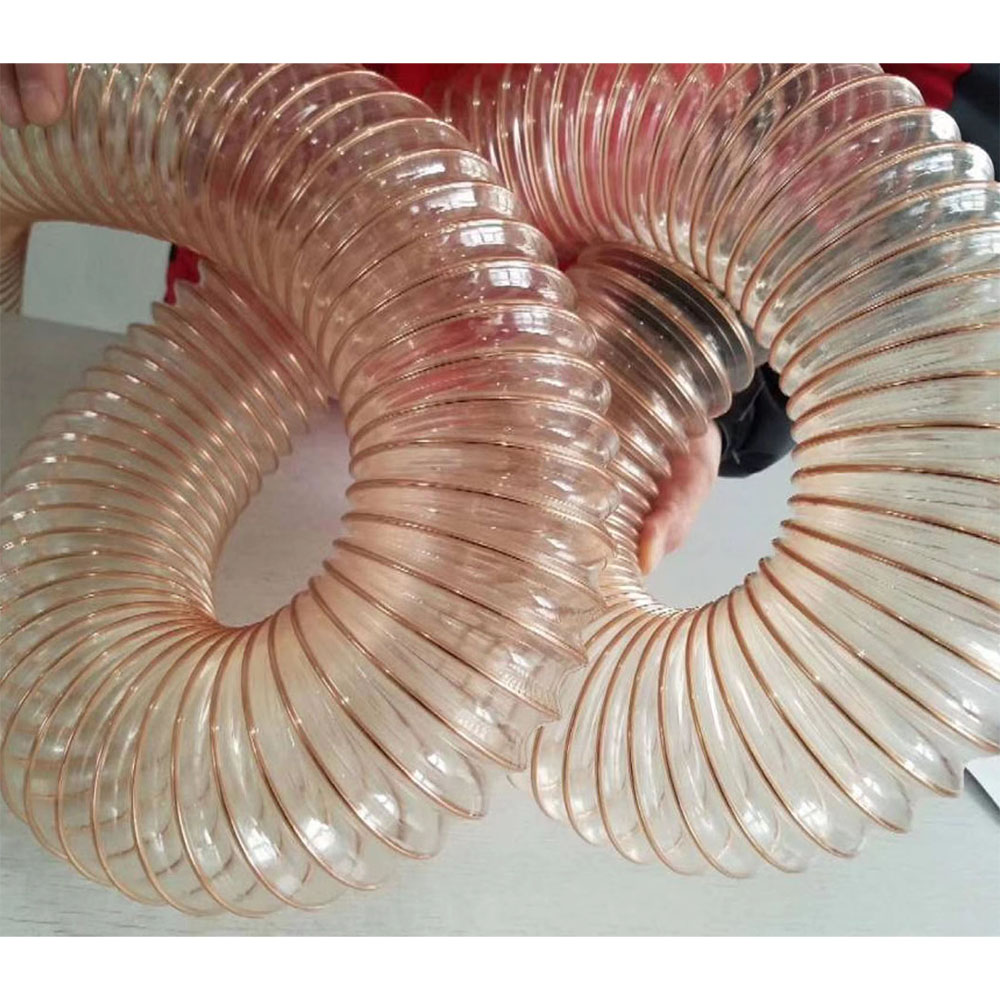

Oxygen and acetylene hoses are essential tools for many industries, including welding, cutting, and metalworking. These hoses are specifically designed to transport gases safely and efficiently, ensuring that the work can be carried out effectively and without risk of accidents.

When it comes to choosing the right oxygen and acetylene hoses for sale, there are a few factors to consider. First and foremost, it is important to ensure that the hoses are made from high-quality materials that are resistant to heat, pressure, and chemicals. This will help to prevent leaks, cracks, and other damage that could compromise the safety of the workers and the integrity of the equipment.

Another important factor to consider when selecting oxygen and acetylene hoses is the size and length of the hoses. It is essential to choose hoses that are long enough to reach the job site without being overly cumbersome, as this could make the work more difficult and time-consuming. Additionally, the diameter of the hoses should be appropriate for the flow rate of the gases being transported, as using hoses that are too narrow could result in a decrease in efficiency and performance.

In addition to the material and size of the hoses, it is also important to consider the type of fittings and connectors that are used

In addition to the material and size of the hoses, it is also important to consider the type of fittings and connectors that are used In addition to the material and size of the hoses, it is also important to consider the type of fittings and connectors that are used

In addition to the material and size of the hoses, it is also important to consider the type of fittings and connectors that are used

In addition to the material and size of the hoses, it is also important to consider the type of fittings and connectors that are used

In addition to the material and size of the hoses, it is also important to consider the type of fittings and connectors that are used oxygen and acetylene hoses for sale. It is essential to ensure that the fittings are compatible with the equipment being used, as using the wrong fittings could result in leaks, pressure loss, and other issues that could compromise the safety of the workers and the quality of the work.

When purchasing oxygen and acetylene hoses for sale, it is also important to consider the reputation of the manufacturer. It is advisable to choose hoses that are made by a reputable company with a track record of producing high-quality products that meet industry standards and regulations. This will help to ensure that the hoses are safe, reliable, and durable, providing peace of mind for the workers and the employers.

Overall, oxygen and acetylene hoses are essential tools for a wide range of industries, and it is important to choose the right hoses for the job. By considering factors such as material, size, fittings, and manufacturer reputation, it is possible to select high-quality hoses that will meet the needs of the workers and the requirements of the job. With the right hoses, work can be carried out safely, efficiently, and effectively, leading to high-quality results and satisfied customers.

oxygen and acetylene hoses for sale. It is essential to ensure that the fittings are compatible with the equipment being used, as using the wrong fittings could result in leaks, pressure loss, and other issues that could compromise the safety of the workers and the quality of the work.

When purchasing oxygen and acetylene hoses for sale, it is also important to consider the reputation of the manufacturer. It is advisable to choose hoses that are made by a reputable company with a track record of producing high-quality products that meet industry standards and regulations. This will help to ensure that the hoses are safe, reliable, and durable, providing peace of mind for the workers and the employers.

Overall, oxygen and acetylene hoses are essential tools for a wide range of industries, and it is important to choose the right hoses for the job. By considering factors such as material, size, fittings, and manufacturer reputation, it is possible to select high-quality hoses that will meet the needs of the workers and the requirements of the job. With the right hoses, work can be carried out safely, efficiently, and effectively, leading to high-quality results and satisfied customers.

In addition to the material and size of the hoses, it is also important to consider the type of fittings and connectors that are used

In addition to the material and size of the hoses, it is also important to consider the type of fittings and connectors that are used

In addition to the material and size of the hoses, it is also important to consider the type of fittings and connectors that are used

In addition to the material and size of the hoses, it is also important to consider the type of fittings and connectors that are used oxygen and acetylene hoses for sale. It is essential to ensure that the fittings are compatible with the equipment being used, as using the wrong fittings could result in leaks, pressure loss, and other issues that could compromise the safety of the workers and the quality of the work.

When purchasing oxygen and acetylene hoses for sale, it is also important to consider the reputation of the manufacturer. It is advisable to choose hoses that are made by a reputable company with a track record of producing high-quality products that meet industry standards and regulations. This will help to ensure that the hoses are safe, reliable, and durable, providing peace of mind for the workers and the employers.

Overall, oxygen and acetylene hoses are essential tools for a wide range of industries, and it is important to choose the right hoses for the job. By considering factors such as material, size, fittings, and manufacturer reputation, it is possible to select high-quality hoses that will meet the needs of the workers and the requirements of the job. With the right hoses, work can be carried out safely, efficiently, and effectively, leading to high-quality results and satisfied customers.

oxygen and acetylene hoses for sale. It is essential to ensure that the fittings are compatible with the equipment being used, as using the wrong fittings could result in leaks, pressure loss, and other issues that could compromise the safety of the workers and the quality of the work.

When purchasing oxygen and acetylene hoses for sale, it is also important to consider the reputation of the manufacturer. It is advisable to choose hoses that are made by a reputable company with a track record of producing high-quality products that meet industry standards and regulations. This will help to ensure that the hoses are safe, reliable, and durable, providing peace of mind for the workers and the employers.

Overall, oxygen and acetylene hoses are essential tools for a wide range of industries, and it is important to choose the right hoses for the job. By considering factors such as material, size, fittings, and manufacturer reputation, it is possible to select high-quality hoses that will meet the needs of the workers and the requirements of the job. With the right hoses, work can be carried out safely, efficiently, and effectively, leading to high-quality results and satisfied customers. Latest news

-

Top Quality Oxy Acetylene Hoses for Sale Fit for Welding DemandsNewsJul.28,2025

-

The Future of Pneumatic Air Tubes in IndustryNewsJul.28,2025

-

Superior and Reliable LPG Hose Pipe Solutions for Every NeedNewsJul.28,2025

-

Exceptionally Durable and Versatile Premium Braided PVC TubingNewsJul.28,2025

-

Best Adapters for Connecting Garden Hose to PVC Pipe ConnectionsNewsJul.28,2025

-

The Essential Role of LPG Hoses in Safe and Efficient Gas DistributionNewsJul.16,2025

HOT PRODUCT

Provide You The Highest Quality Work

INQUIRE