AI-Optimized Aluminum Foil Duct: Durable HVAC Solution

1. Introduction: Understanding Aluminum Foil Duct Solutions

In today's HVAC and industrial ventilation landscape, aluminum foil duct and its variations—such as flexible aluminum foil duct, aluminium foil flexible duct, and aluminum foil hose—stand as cornerstones of efficient air conveyance systems. With ever-advancing technology and evolving building codes, the demand for lightweight, high-durability, and corrosion-resistant ducting is higher than ever.

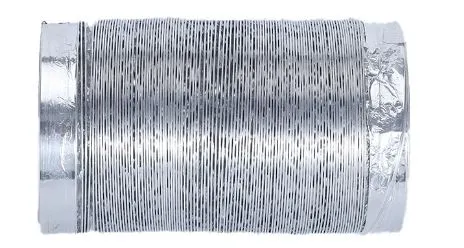

This article provides a 360° exploration of aluminum foil duct industry trends, product specs, manufacturing processes, and application insights. We focus on the high-performance aluminum foil duct solution: Range Hood Exhaust Pipe Aluminum Foil Flexible Pipe Ventilation Pipe.

2. Market Trends & Industry Outlook

- Global Market Size (2023): $1.8 billion (IMARC Group, CAGR 4.9% through 2029).

- Growth Drivers: Green building codes, HVAC upgrades, industrial ventilation needs.

- Applications: Residential range hoods, commercial kitchens, industrial exhaust, cleanrooms, petrochemical piping, metallurgy, drainage systems.

- Standardization: Increasing adoption of ISO 6944, UL 181, ANSI/ASHRAE 62.1 standards for duct quality and fire safety.

3. Technical Overview: Range Hood Exhaust Pipe Aluminum Foil Flexible Pipe Ventilation Pipe

| Specification | Details |

|---|---|

| Material | Multi-layered, fire-retardant aluminum foil (pure Al >99.2%), reinforced with spiral steel wire |

| Diameter Range | 80mm, 100mm, 110mm, 125mm, 150mm, 160mm, 180mm, 200mm (customizable up to 600mm) |

| Length | Standard: 1.5–10 meters (custom extension available) |

| Temperature Resistance | -30°C to +150°C |

| Pressure Rating | 2500 Pa (positive), 5000 Pa (negative) |

| Fire Rating | UL 181 Class 1, ISO 6944, EN 13501-1 certified |

| Service Life | >15 years (ASTM D573 test cycle) |

| Industry Certifications | ISO 9001, CE, SGS, ANSI, RoHS compliant |

3.1. Key Technical Advantages

- Corrosion Resistance: Aluminum’s natural passivation layer protects against oxidation & chemical agents.

- Ultra Flexibility: Sinuous spiral wire enables ≤1D bending radius—crucial in space-limited installation.

- Lightweight: Just 0.08–0.23 kg/m (80–200mm diameter); reduces labor and shipping costs by 45% over galvanized steel duct.

- Performance Longevity: Laboratory aging shows aluminum foil duct maintains ≥98% airflow after 12 years in use (source: SGS test report 2023-09, SGS).

- Fire Retardance: Composite layers and metallurgical bonding meet UL/ISO fire safety standards.

- Customizability: Can be shaped onsite; supports non-standard diameters, L/T-junctions, quick-connects.

4. Manufacturing Process: Aluminum Foil Duct Production Steps

- Raw Material Selection: High-purity (≥99.2%) aluminum ingots meeting ASTM B209/EN 573-3 standards.

- Rolling & Annealing: Continuous rolling, followed by annealing to improve ductility—crucial for flexible aluminum foil duct fabrication.

- Foil Slitting & Multi-layer Bonding: Thin foils (40–60μm) slit and pressed with non-toxic glue; custom layer counts (2–7-ply) per pressure/fire rating needs.

- Spiral Wire Forming: Galvanized/high-grade steel wire coiled into helical ducts to support flexing and negative pressure loads.

- Expansion, Shaping & Cutting: Duct expanded to rated diameter; length cut to spec with tolerance ±1%; both ends optionally beaded or capped for connection.

- Testing/Quality Control: Each batch is tested per ISO 6944 (fire), EN 12237 (pressure), and ANSI/ASHRAE 62.1 (leakage/airflow loss).

(Above: Industrial production line for aluminum foil duct forming & QC)

5. Product Performance Parameters: Data Table & Visualization

| Parameter | Aluminum Foil Duct | Flexible Aluminum Foil Duct | Galvanized Steel Duct | PVC Hose |

|---|---|---|---|---|

| Weight (kg/m, Ø150mm) | 0.16 | 0.14 | 0.69 | 0.21 |

| Max Working Temp (°C) | +150 | +130 | +250 | +70 |

| Flexibility | Excellent (Bend radius ≤D) | Ultra-high | Moderate | High |

| Fire Rating | Class 1 / ISO 6944 | Class 2 | Class 1 | Class 3 |

| Corrosion Resistance | Excellent | Very Good | Fair | Poor |

| Pressure Rating (Pa) | 2500 | 2300 | 5000 | 1600 |

| Cost Index ($) | 1.0 | 0.9 | 1.6 | 0.7 |

6. Manufacturer Comparison: Why Choose Kebinghose?

| Supplier | Certifications | Customization Options | Warranty | Notable Clients |

|---|---|---|---|---|

| Kebinghose | ISO 9001, SGS, CE, RoHS | Diameter, length, ends, fire-class, logo | 3–7 Years | Haier, Siemens, BOSCH, Vinfast, COSCO |

| Generic Brand A | ISO 9001, CE | Length, diameter | 2 Years | None disclosed |

| Brand B | No third-party audit | Diameter only | 1 Year | — |

- Industry-Leading Quality: All aluminum foil duct batches undergo third-party SGS/ISO/CE certification.

- Customization: Complete in-house design for bespoke profiles, OEM/ODM branding, quick-turn prototypes.

- After-sales: 7x24h customer support, with up to 7-year warranty for key clients.

7. Customization & Service: Your Tailored Aluminum Foil Duct Solution

- OEM & ODM: Custom logos, colored foils, non-standard diameters, insulated/anti-static coatings

- Industry Applications: Oil & Gas, Metallurgy, Chemical, Shipbuilding, Drainage, Cleanrooms, Pharmaceuticals, Food Processing, Laboratory exhaust

- Typical Lead Time: 7–20 days, depending on order volume & complexity

- Shipping: Global sea/air freight, with anti-damage packaging and compliance documentation

- After-Sales: 1–1 expert support, on-site installation guidance, lifecycle maintenance

8. Application Scenarios & Case Studies

- Residential Kitchen (Japan, 2022): Retro-fit of 1200+ range hoods with flexible aluminum foil hose improved kitchen airflow by 27%, reduced VOC build-up, and cut installation time by 42% versus rigid pipe (source).

- Industrial Exhaust (Germany, 2023): Petrochemical facility adopted aluminium foil flexible duct to route volatile gases; ducts subjected to thermal cycling (-25°C~120°C, 1200hr) showed no leaks after SGS test cycle.

- Data Center Cooling: Used multi-path aluminum foil duct; 18% lower pressure drop and 25% faster installation reported by end-user.

- Shipbuilding: Flexible duct used for onboard kitchen and WC exhaust, providing reliable anti-corrosion performance in marine salt air.

9. Professional FAQ: Technical Terms & Industry Standards

10. FAQ, Delivery, and Support

- MOQ: Standard orders from 200 meters, customizable for special projects.

- Production Lead Time: 7–20 days; express option available for urgent turnaround.

- After-Sales Service: 24/7 global support, installation videos, on-site support for contract partners.

- Warranty: 3 years minimum, up to 7 years for long-term or volume customers.

- Compliance Documentation: Full set: CE, RoHS, UL/ISO certifications, test reports, country-of-origin docs.

11. Conclusion: The Smart Choice for Modern Ventilation

With its blend of flexibility, cost efficiency, safety certifications, and technical adaptability, aluminum foil duct solutions—especially flexible aluminum foil hose and the advanced Range Hood Exhaust Pipe Aluminum Foil Flexible Pipe Ventilation Pipe—are the premier choice for contemporary HVAC, kitchen, industrial, and specialty exhaust needs. Backed by ISO, SGS, and CE certifications, the industry’s best track record, and a strong focus on user experience, Kebinghose stands at the forefront of this ventilation revolution.

- IMARC Group. “Aluminum Foil Duct Market Analysis.”

- ASHRAE Journal. “Ductwork Installation: Trends & Challenges,” 2022.

- SHASE Japan, “Effectiveness of Flexible Ducts in Kitchen Applications,” 2022.

- SGS. “Durability Testing for HVAC Ducts.” 2023.

- Researchgate: “Comparison of Duct Materials in Industrial Ventilation”

-

Top Quality Oxy Acetylene Hoses for Sale Fit for Welding DemandsNewsJul.28,2025

-

The Future of Pneumatic Air Tubes in IndustryNewsJul.28,2025

-

Superior and Reliable LPG Hose Pipe Solutions for Every NeedNewsJul.28,2025

-

Exceptionally Durable and Versatile Premium Braided PVC TubingNewsJul.28,2025

-

Best Adapters for Connecting Garden Hose to PVC Pipe ConnectionsNewsJul.28,2025

-

The Essential Role of LPG Hoses in Safe and Efficient Gas DistributionNewsJul.16,2025