Durable Wire-Reinforced Suction Hose for Enhanced Performance and Flexibility in Various Applications

Understanding Wire Reinforced Suction Hose Applications, Benefits, and Considerations

In various industrial and construction settings, the demands for durable and high-performance materials are paramount. One such versatile product that has gained popularity is the wire reinforced suction hose. This unique type of hose combines the flexibility required for a range of applications with the necessary strength to withstand harsh conditions.

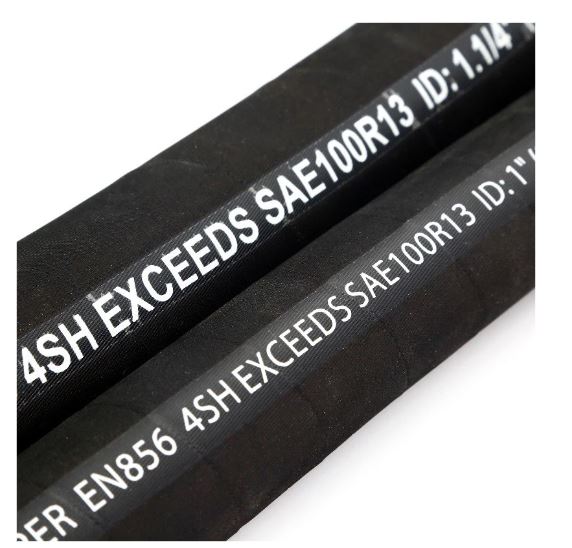

What is Wire Reinforced Suction Hose?

Wire reinforced suction hose is a specialized type of hose designed to convey liquids and some solids in a multitude of applications. Its construction typically involves a soft PVC or rubber tube with embedded wire spirals, which provide added support and prevent the hose from collapsing under negative pressure. This reinforcement makes it particularly suitable for suction applications where the hose may be subjected to various forces, including bending and pressure changes.

Key Features

1. Flexibility and Strength The wire reinforcement allows the hose to easily navigate around tight corners without kinking or collapsing. This flexibility is essential in environments where pipes need to be maneuvered frequently.

2. Pressure Resistance The hose is designed to handle both positive and negative pressure, making it an ideal choice for suction purposes. The wire spirals help maintain the shape of the hose, ensuring that it stays functional even when subjected to high suction forces.

3. Chemical Resistance Many wire reinforced suction hoses are available with chemical-resistant coatings, making them suitable for handling various industrial liquids. This property is crucial in chemical processing plants, where exposure to corrosive substances is common.

4. Temperature Resilience The materials used in its manufacture often allow it to perform effectively in a wide range of temperatures, making it suitable for various climates and industrial environments.

Applications

Wire reinforced suction hoses are widely utilized across multiple industries, including

- Agriculture In farming, these hoses are often used for transferring water, fertilizers, and pesticides from tanks to fields. Their durability ensures reliability during critical agricultural operations.

wire reinforced suction hose

- Construction In the construction industry, they are used for the transfer of concrete, slurry, and other mixtures. Their ability to handle heavy loads and rough handling makes them ideal for such demanding conditions.

- Industrial Cleaning The hoses are frequently employed in industrial vacuum applications for suctioning waste materials, debris, and liquid spills. Their strength ensures that they can function efficiently without the risk of damage.

- Food and Beverage Specially designed wire reinforced suction hoses meet strict food safety standards and are used in the transport of liquids like juices, milk, and other consumables.

Considerations When Choosing Wire Reinforced Suction Hose

When selecting a wire reinforced suction hose, several factors must be considered to ensure it meets the specific requirements of the application

1. Diameter and Length The diameter of the hose should match the needs of the system it is intended for, ensuring optimal flow rates. Length is another important aspect, as it must be sufficient to reach from the source to the destination without creating unnecessary bends.

2. Material Compatibility Ensure that the hose material is compatible with the liquids or solids it will convey. Incompatible materials can lead to hose degradation, leaks, or contamination of the conveyed substances.

3. Pressure Ratings Verify the pressure ratings of the hose to ensure that it can handle the specific pressures it will face during operation.

4. Temperature Range Select a hose that can withstand the temperature conditions of the application, whether it involves hot liquids, cold temperatures, or varying environmental conditions.

5. Regulatory Compliance For applications involving food or chemicals, ensure the hose meets relevant industry standards and regulations to guarantee safety and compliance.

Conclusion

Wire reinforced suction hoses are indispensable tools in many industrial and agricultural applications. Their blend of flexibility, strength, and durability makes them well-suited for a variety of situations requiring reliable fluid transfer. By understanding the features and benefits of these hoses, as well as considering the critical factors when selecting one for specific needs, professionals can enhance efficiency and safety across their operations.

-

Top Quality Oxy Acetylene Hoses for Sale Fit for Welding DemandsNewsJul.28,2025

-

The Future of Pneumatic Air Tubes in IndustryNewsJul.28,2025

-

Superior and Reliable LPG Hose Pipe Solutions for Every NeedNewsJul.28,2025

-

Exceptionally Durable and Versatile Premium Braided PVC TubingNewsJul.28,2025

-

Best Adapters for Connecting Garden Hose to PVC Pipe ConnectionsNewsJul.28,2025

-

The Essential Role of LPG Hoses in Safe and Efficient Gas DistributionNewsJul.16,2025