Wire-Reinforced Plastic Tubing for Enhanced Durability and Versatile Applications

Wire Reinforced Plastic Tubing An Innovative Solution for Various Applications

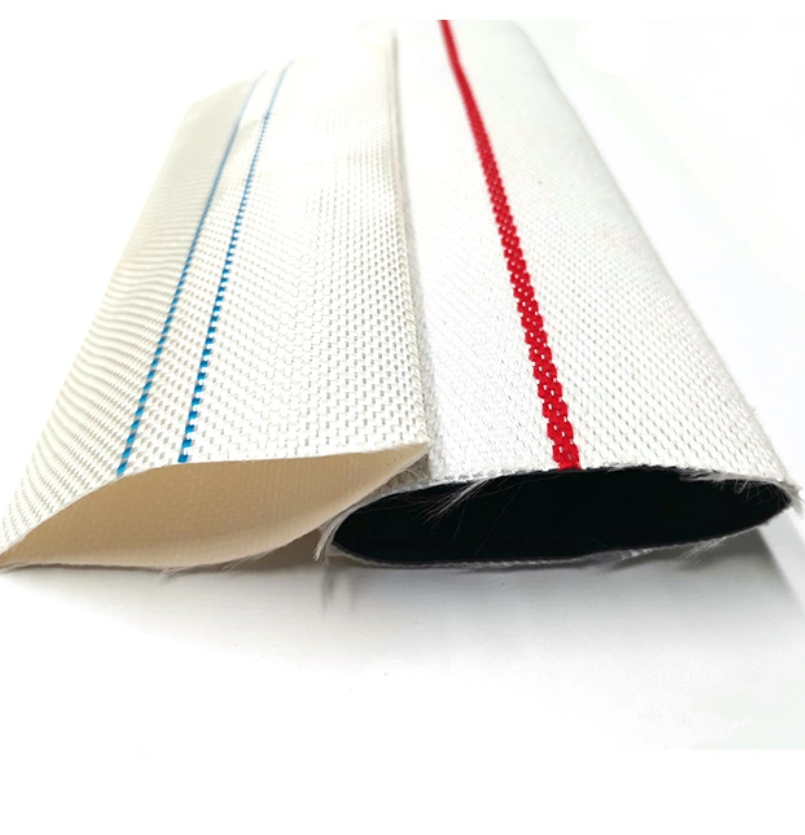

Wire reinforced plastic tubing (WRPT) is an advanced material that has gained significant popularity across various industries due to its unique characteristics and versatility. This innovative product combines the lightweight and flexible properties of plastic with the strength and durability provided by metallic wire reinforcement. This article will delve into the composition, advantages, applications, and future prospects of wire reinforced plastic tubing.

Composition and Manufacturing Process

Wire reinforced plastic tubing is typically constructed using high-density polyethylene (HDPE) or polyvinyl chloride (PVC) as the primary plastic component. The reinforcement usually consists of steel or other durable metal wire, which is integrated into the tubing during the manufacturing process. The manufacturing techniques often involve extruding the plastic in conjunction with weaving or coiling the wire to create a composite structure. This method ensures that the wire is evenly distributed throughout the tubing, thus enhancing its strength and resistance to deformation.

Advantages of Wire Reinforced Plastic Tubing

1. Enhanced Durability One of the most significant advantages of WRPT is its enhanced durability. The wire reinforcement significantly increases the tubing’s resistance to impact, abrasion, and various environmental factors. This makes it ideal for applications in harsh conditions where standard plastic tubing may fail.

2. Lightweight and Flexible WRPT retains the lightweight characteristics of plastic, making it easier to handle and install compared to traditional metal tubing. Its flexibility allows for easier bending and maneuvering, enabling it to be used in applications where rigid piping would be impractical.

3. Chemical Resistance Plastic materials like HDPE and PVC possess excellent resistance to a wide range of chemicals, including acids, bases, and solvents. This property is crucial for applications in chemical processing, agriculture, and wastewater management.

4. Cost-Effective The combination of materials used in wire reinforced plastic tubing results in a product that is both cost-effective and efficient. The manufacturing process allows for large-scale production, reducing costs and making it an attractive option for many businesses.

5. Reduced Noise and Vibration The composite structure of WRPT helps to minimize noise and vibration, making it suitable for use in sensitive environments such as hospitals and laboratories where sound levels need to be controlled.

wire reinforced plastic tubing

Applications of Wire Reinforced Plastic Tubing

The applications of wire reinforced plastic tubing are diverse and span multiple industries

- Agriculture WRPT is widely used for irrigation systems, allowing for the efficient transport of water and nutrients without the risk of damage from external pressures or impacts. - Construction In the construction sector, wire reinforced plastic tubing is utilized for drainage systems and as conduits for electrical wiring. Its durability and resistance to corrosion make it preferable for underground installations.

- Chemical Processing Due to its chemical resistance, WRPT is ideal for transporting and handling various chemicals in industrial settings. It can withstand extreme conditions without degrading.

- Healthcare In medical applications, WRPT is used for various purposes, including fluid transfer and gas delivery systems. Its flexibility and lightweight nature facilitate installation in complex environments.

- Automotive and Aerospace The aerospace and automotive industries also benefit from WRPT for fuel lines and other applications where lightweight materials are essential for overall efficiency.

Future Prospects

As industries continue to evolve, the demand for innovative materials such as wire reinforced plastic tubing is expected to rise. Research is ongoing to develop even more advanced composites that enhance the performance characteristics of WRPT, such as increased fire resistance and improved sustainability through the use of recycled materials.

In summary, wire reinforced plastic tubing represents a remarkable fusion of strength, durability, and versatility. Its unique properties make it an invaluable solution across various sectors, ranging from agriculture to aerospace. As advancements continue in material science and production methods, the future of wire reinforced plastic tubing looks promising, paving the way for new innovations that can further enhance its applications and capabilities.

-

Top Quality Oxy Acetylene Hoses for Sale Fit for Welding DemandsNewsJul.28,2025

-

The Future of Pneumatic Air Tubes in IndustryNewsJul.28,2025

-

Superior and Reliable LPG Hose Pipe Solutions for Every NeedNewsJul.28,2025

-

Exceptionally Durable and Versatile Premium Braided PVC TubingNewsJul.28,2025

-

Best Adapters for Connecting Garden Hose to PVC Pipe ConnectionsNewsJul.28,2025

-

The Essential Role of LPG Hoses in Safe and Efficient Gas DistributionNewsJul.16,2025