vacuum pump hose

The Importance of Vacuum Pump Hoses in Industrial Applications

In various industrial applications, the efficiency of a vacuum pump system largely depends on the quality and integrity of the components involved. Among these components, vacuum pump hoses play a crucial role. These hoses are specifically designed to transport gases or vapors under vacuum conditions, making them essential in a range of processes, from manufacturing to laboratory experiments. This article delves into the significance of vacuum pump hoses, their types, and considerations for selection and maintenance.

Understanding Vacuum Pump Hoses

Vacuum pump hoses are flexible tubes made to withstand the negative pressure created by vacuum pumps. They help in connecting the vacuum pump to the system or equipment it maintains. These hoses can carry various gases, from air to more complex chemical vapors, depending on the materials they are constructed from.

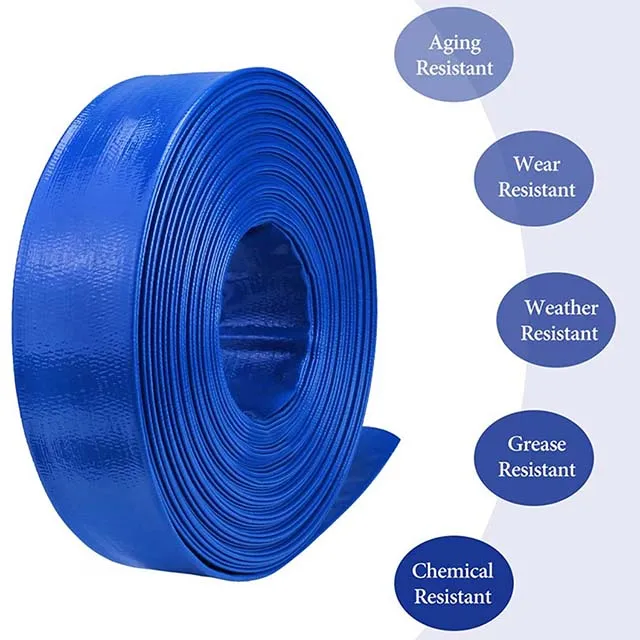

The construction material is critical, as it determines the hose's compatibility with the substances being transported. Common materials include rubber, silicone, PVC, and reinforced plastics, each offering different properties such as temperature resistance, chemical resistance, and flexibility.

Types of Vacuum Pump Hoses

1. Standard Vacuum Hoses These are general-purpose hoses suitable for basic vacuum applications. Typically made from rubber or PVC, they can handle a range of gases but may not be suitable for high-temperature or corrosive environments.

2. Chemical-Resistant Hoses Designed to transport aggressive chemicals, these hoses are often made from specialty materials that can withstand corrosion and physical wear. They are crucial in laboratory settings or chemical processing plants.

3. High-Temperature Vacuum Hoses For applications involving elevated temperatures, high-temperature vacuum hoses are vital. Made from materials such as silicone or fluoropolymers, these hoses can operate effectively in extreme heat without degrading or losing their integrity.

4. Reinforced Hoses These hoses contain internal reinforcing layers which provide additional strength and resistance to collapse under high vacuum conditions. They are ideal for heavy-duty applications and situations requiring suction from a significant distance.

5. Anti-Static Hoses In environments where static electricity can be a hazard, anti-static vacuum hoses are necessary. They help prevent the buildup of static charges that could lead to accidents or discharge.

Considerations for Selection

vacuum pump hose

When selecting a vacuum pump hose, several factors need to be considered

- Chemical Compatibility It is crucial to choose a hose material that can withstand the chemicals being transported. Failure to do so can lead to leaks or hose degradation.

- Temperature Range Assess the maximum and minimum temperatures the hose will encounter to choose a suitable material.

- Diameter and Length Ensure that the hose diameter matches the fittings on the vacuum pump and that the length is adequate for your setup. Larger diameters can reduce resistance but may increase the volume of air that must be evacuated.

- Vacuum Rating Different hoses have different vacuum ratings, indicating the maximum vacuum level they can maintain without collapsing. Always verify that the selected hose can handle the desired vacuum level.

- Flexibility and Maneuverability Depending on the application, flexibility might be essential for installation in tight spaces.

Maintenance and Care

Proper maintenance of vacuum pump hoses is vital to ensure longevity and functionality. Regular inspections should be conducted to check for signs of wear, cracking, or corrosion. Hoses should be cleaned regularly using appropriate cleaning agents that won't damage the hose material.

Additionally, it is essential to avoid sharp bends and kinks, as these can create weak points in the hose, which may lead to failure under vacuum conditions. Always follow the manufacturer's guidelines for both installation and maintenance for optimal performance.

Conclusion

In summary, vacuum pump hoses are a fundamental component in various industries, enabling the transport of gases and vapors efficiently and safely. Selecting the right type of hose based on material properties, compatibility, and application requirements is crucial for optimizing the vacuum system's performance. By understanding the importance of these hoses and committing to regular maintenance, industries can ensure operational efficiency and safety in their processes. Investing in high-quality vacuum pump hoses is not just a choice; it’s a necessary step towards reliability and performance in any vacuum-based application.

-

Welded Wire Mesh Panel: Durable, Versatile, and AffordableNewsJul.28,2025

-

Top Quality Oxy Acetylene Hoses for Sale Fit for Welding DemandsNewsJul.28,2025

-

The Future of Pneumatic Air Tubes in IndustryNewsJul.28,2025

-

Superior and Reliable LPG Hose Pipe Solutions for Every NeedNewsJul.28,2025

-

Exceptionally Durable and Versatile Premium Braided PVC TubingNewsJul.28,2025

-

Best Adapters for Connecting Garden Hose to PVC Pipe ConnectionsNewsJul.28,2025