Jan . 25, 2025 01:11

Back to list

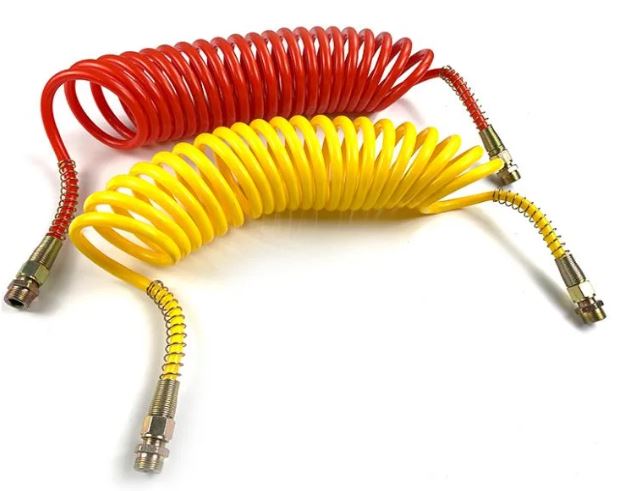

vacuum pipes

Navigating the World of Vacuum Pipes A Comprehensive Guide to Choosing the Right Structural Component

Innovations in vacuum technology have led to the development of flexible vacuum piping systems, which offer enhanced adaptability and ease of installation. These systems can be particularly advantageous in setups requiring frequent reconfiguration or expansion. With advancements in material science, these flexible solutions now offer comparable durability and performance to their rigid counterparts, without the added weight and complexity. Installation practices are key to maximizing the performance and longevity of vacuum pipes. Proper installation minimizes leaks, enhances efficiency, and safeguards against potential system failures. Use of correctly calibrated sealing elements and ensuring secure fitting connections will prevent loss of pressure and contamination from external environments, thereby maintaining system integrity. Understanding the maintenance requirements for vacuum pipes is equally essential. Regular inspections for signs of wear, corrosion, or damage can preempt costly repairs or system downtimes. Implementing a routine cleaning schedule, especially in environments prone to dirt and particulate buildup, will keep the pipes functioning optimally. For anyone new to vacuum technologies, consulting with an expert or manufacturer provides insights into specific needs and limitations. By leveraging expertise from industry leaders and utilizing advanced resources, businesses and individuals can make informed decisions that optimize the selection and application of vacuum pipes. In conclusion, vacuum pipes are integral to the functionality and efficiency of numerous applications. Whether used in high-tech laboratories or expansive manufacturing facilities, understanding their characteristics, applications, and maintenance is crucial to ensuring optimal performance and longevity. By prioritizing expert insights and adopting best practices in installation and maintenance, users can effectively harness the full potential of these critical components.

Innovations in vacuum technology have led to the development of flexible vacuum piping systems, which offer enhanced adaptability and ease of installation. These systems can be particularly advantageous in setups requiring frequent reconfiguration or expansion. With advancements in material science, these flexible solutions now offer comparable durability and performance to their rigid counterparts, without the added weight and complexity. Installation practices are key to maximizing the performance and longevity of vacuum pipes. Proper installation minimizes leaks, enhances efficiency, and safeguards against potential system failures. Use of correctly calibrated sealing elements and ensuring secure fitting connections will prevent loss of pressure and contamination from external environments, thereby maintaining system integrity. Understanding the maintenance requirements for vacuum pipes is equally essential. Regular inspections for signs of wear, corrosion, or damage can preempt costly repairs or system downtimes. Implementing a routine cleaning schedule, especially in environments prone to dirt and particulate buildup, will keep the pipes functioning optimally. For anyone new to vacuum technologies, consulting with an expert or manufacturer provides insights into specific needs and limitations. By leveraging expertise from industry leaders and utilizing advanced resources, businesses and individuals can make informed decisions that optimize the selection and application of vacuum pipes. In conclusion, vacuum pipes are integral to the functionality and efficiency of numerous applications. Whether used in high-tech laboratories or expansive manufacturing facilities, understanding their characteristics, applications, and maintenance is crucial to ensuring optimal performance and longevity. By prioritizing expert insights and adopting best practices in installation and maintenance, users can effectively harness the full potential of these critical components.

Next:

Latest news

-

Top Quality Oxy Acetylene Hoses for Sale Fit for Welding DemandsNewsJul.28,2025

-

The Future of Pneumatic Air Tubes in IndustryNewsJul.28,2025

-

Superior and Reliable LPG Hose Pipe Solutions for Every NeedNewsJul.28,2025

-

Exceptionally Durable and Versatile Premium Braided PVC TubingNewsJul.28,2025

-

Best Adapters for Connecting Garden Hose to PVC Pipe ConnectionsNewsJul.28,2025

-

The Essential Role of LPG Hoses in Safe and Efficient Gas DistributionNewsJul.16,2025

HOT PRODUCT

Provide You The Highest Quality Work

INQUIRE