twin welding hose 8mm

The Importance of Twin Welding Hoses in Modern Industries

In the realm of industrial welding, the choice of equipment and materials directly influences the efficiency, safety, and quality of work. One such critical component is the twin welding hose, particularly those with a diameter of 8mm. This specialized hose plays a pivotal role in supplying gases such as oxygen and acetylene to welding torches, facilitating a range of applications from metal fabrication to repair work.

Understanding Twin Welding Hoses

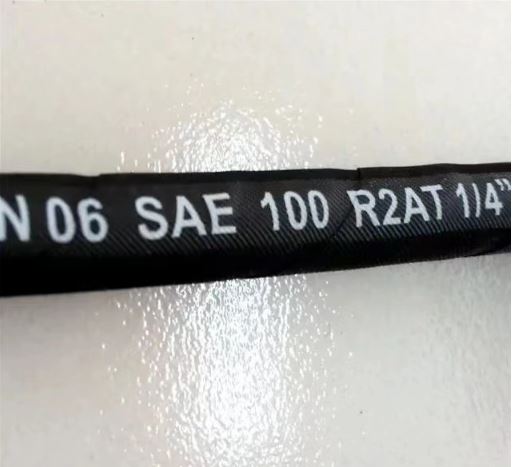

A twin welding hose consists of two parallel tubes, typically made from rubber or other resilient materials, designed to transport fuel gases and oxygen simultaneously. The 8mm diameter is standard for many welding operations, providing an optimal balance between flexibility and flow capacity. Each tube is color-coded to distinguish between the two gases, usually with one being red for acetylene and the other being green or blue for oxygen. This visual representation is crucial in preventing confusion, ensuring that welders maintain safety protocols during operations.

Advantages of Twin Welding Hoses

1. Efficiency Utilizing a twin hose allows for a streamlined approach to welding. Instead of managing multiple hoses, a single unit handles both gases, minimizing tangling and simplifying the setup process. This efficiency translates to quicker job completion times, which is a significant factor in competitive industries.

2. Safety The design of twin welding hoses contributes to workplace safety. By maintaining separate channels for fuel and oxidizer within the same hose, the risk of flashback (the backward movement of flame into the hoses) is reduced. Additionally, many hoses are equipped with built-in safety features such as flashback arrestors and check valves to further enhance protection against accidents.

3. Durability High-quality twin welding hoses are designed to withstand the rigors of welding environments, which can involve exposure to extreme temperatures and harsh conditions. The 8mm hoses are often reinforced to resist kinks, abrasions, and cuts, ensuring a longer lifespan compared to single or inferior quality hoses.

twin welding hose 8mm

4. Versatility Twin welding hoses are not limited to just one type of welding process. They can be used for various welding techniques, including oxy-acetylene welding, brazing, and cutting. Their adaptability makes them an essential tool across multiple applications, from small workshops to large manufacturing lines.

Applications in Various Industries

The versatility of 8mm twin welding hoses makes them invaluable across numerous sectors. In automotive repair shops, for instance, mechanics rely on these hoses for efficient welding and braze jobs. In construction and metalwork, the hoses facilitate structural fabrication, allowing workers to join metals securely. The shipbuilding industry also benefits from twin welding hoses for repairs and hull fabrication, where precision and reliability are paramount.

Proper Maintenance and Care

To ensure the longevity and safe operation of twin welding hoses, proper maintenance is essential. Users should routinely inspect the hoses for signs of wear, such as cracks or abrasions. Additionally, it’s critical to check the connections and fittings for leaks, as even a small gas leak can pose significant dangers. Hoses should be stored in a clean, dry environment away from direct sunlight and sharp objects to prevent damage.

Conclusion

In summary, 8mm twin welding hoses are indispensable in the modern industrial landscape. Their design optimizes both efficiency and safety, making them a preferred choice for professionals in welding and metalwork. As industries continue to evolve and demand higher standards of safety and quality, the importance of reliable equipment such as twin welding hoses will only grow. Investing in high-quality hoses not only ensures better results in welding operations but also contributes to a safer workplace, allowing professionals to focus on their craft with peace of mind. Whether you are in a bustling manufacturing facility or a small workshop, a twin welding hose is a critical asset that is too valuable to overlook.

-

Top Quality Oxy Acetylene Hoses for Sale Fit for Welding DemandsNewsJul.28,2025

-

The Future of Pneumatic Air Tubes in IndustryNewsJul.28,2025

-

Superior and Reliable LPG Hose Pipe Solutions for Every NeedNewsJul.28,2025

-

Exceptionally Durable and Versatile Premium Braided PVC TubingNewsJul.28,2025

-

Best Adapters for Connecting Garden Hose to PVC Pipe ConnectionsNewsJul.28,2025

-

The Essential Role of LPG Hoses in Safe and Efficient Gas DistributionNewsJul.16,2025