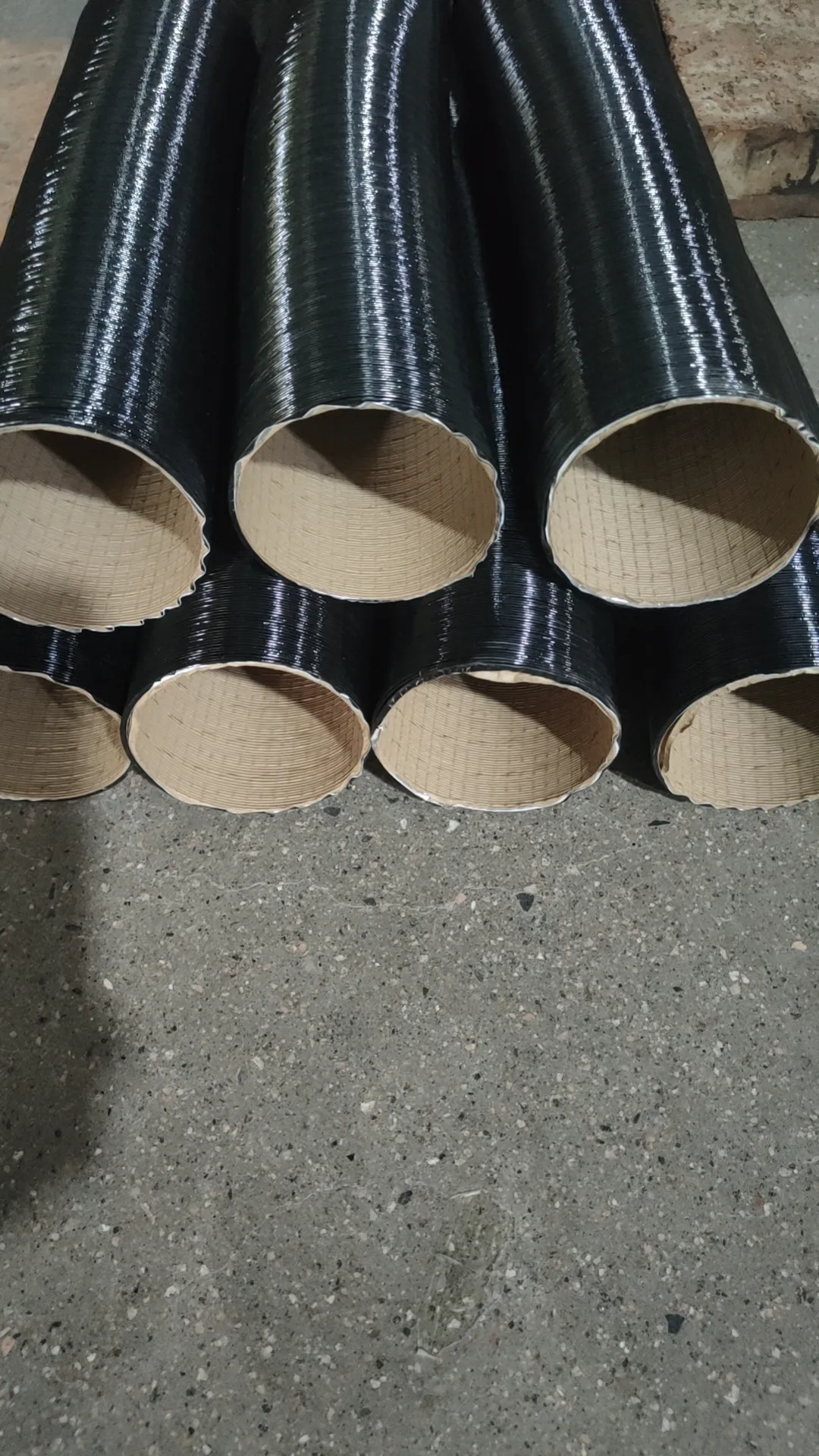

tubing for vacuum pump

Tubing for Vacuum Pumps Essential Considerations and Materials

Vacuum pumps are critical components in various industrial and scientific applications, including chemical processing, semiconductor manufacturing, and laboratory research. One of the essential aspects of a vacuum pump system is the tubing used to connect the pump to its application. The selection of appropriate tubing is crucial for ensuring optimal performance, efficiency, and longevity of the system. This article explores the key considerations and materials involved in choosing tubing for vacuum pumps.

Key Considerations

1. Pressure Rating Tubing for vacuum applications must be able to withstand the negative pressures that occur within a vacuum system. The pressure rating of the tubing should exceed the maximum operating pressure of the vacuum pump to prevent any collapse or rupture, which could lead to system failure.

2. Chemical Compatibility The materials used in tubing must be compatible with the substances they will transport. For instance, if corrosive gases or aggressive solvents are being pumped, it is important to select tubing materials that can resist chemical degradation. This compatibility helps to maintain the integrity of both the tubing and the materials being processed.

3. Flexibility and Bend Radius Tubing must have enough flexibility to accommodate the layout of the installation without kinking. Kinks in the tubing can create blockages, which reduce efficiency and potentially damage the pump. A minimum bend radius should be defined based on the material and diameter of the tubing to ensure that it does not restrict flow or compromise performance.

4. Temperature Resistance Many vacuum applications involve elevated temperatures, which can affect the integrity of the tubing. Understanding the thermal characteristics of the chosen material is essential, especially for processes involving heat. Tubing should be able to withstand the operating temperature range of the system without deformation or degradation.

5. Size and Diameter The inner diameter of the tubing must be appropriately sized to facilitate the desired flow rate. Using tubing that is too small can create excessive resistance and reduce the effectiveness of the vacuum pump. Conversely, tubing that is too large may lead to inefficient pumping. An optimal balance should be struck based on the specific requirements of the application.

Tubing Materials

tubing for vacuum pump

When selecting tubing for vacuum applications, a variety of materials are available, each with unique properties and advantages.

1. PVC (Polyvinyl Chloride) PVC is a widely-used plastic that offers good chemical resistance and flexibility at a low cost. However, it may not be suitable for high-temperature or high-vacuum applications.

2. Silicone Silicone tubing is highly flexible and able to withstand a wide temperature range, making it an excellent choice for laboratory settings. It is resistant to various chemicals, though it should be evaluated for compatibility with specific substances being transported.

3. Teflon (PTFE) Teflon tubing is renowned for its exceptional chemical resistance and ability to operate in extreme temperatures. It is an ideal choice for aggressive chemicals and ultra-high vacuum systems, although it is generally more expensive than other materials.

4. Stainless Steel For industrial applications where durability and high vacuum levels are critical, stainless steel tubing is often the preferred material. It can withstand high pressures and temperatures while providing excellent resistance to corrosion. It is also easy to clean and sterilize, making it suitable for pharmaceutical and food applications.

5. Glass In specialized scientific settings, glass tubing may be employed for its transparency and chemical resistance. However, it is typically less flexible and more fragile compared to other options.

Conclusion

Choosing the right tubing for a vacuum pump system is crucial for maintaining the efficiency and longevity of the entire system. By considering factors such as pressure rating, chemical compatibility, flexibility, temperature resistance, and material choice, one can ensure a reliable connection between the pump and its application. This choice ultimately impacts the overall performance of the vacuum system, making it essential for operators and engineers to devote appropriate attention to this often-overlooked aspect of vacuum technology.

-

Welded Wire Mesh Panel: Durable, Versatile, and AffordableNewsJul.28,2025

-

Top Quality Oxy Acetylene Hoses for Sale Fit for Welding DemandsNewsJul.28,2025

-

The Future of Pneumatic Air Tubes in IndustryNewsJul.28,2025

-

Superior and Reliable LPG Hose Pipe Solutions for Every NeedNewsJul.28,2025

-

Exceptionally Durable and Versatile Premium Braided PVC TubingNewsJul.28,2025

-

Best Adapters for Connecting Garden Hose to PVC Pipe ConnectionsNewsJul.28,2025