transfer hose

Understanding Transfer Hoses Essential Tools for Fluid Management

Transfer hoses play a crucial role in various industries, particularly in the transportation and management of fluids. Whether it’s oil, chemicals, water, or food-grade liquids, these hoses are designed to facilitate quick, efficient, and safe transfer. Understanding the specifications, applications, and maintenance of transfer hoses is essential for industries reliant on fluid management.

What are Transfer Hoses?

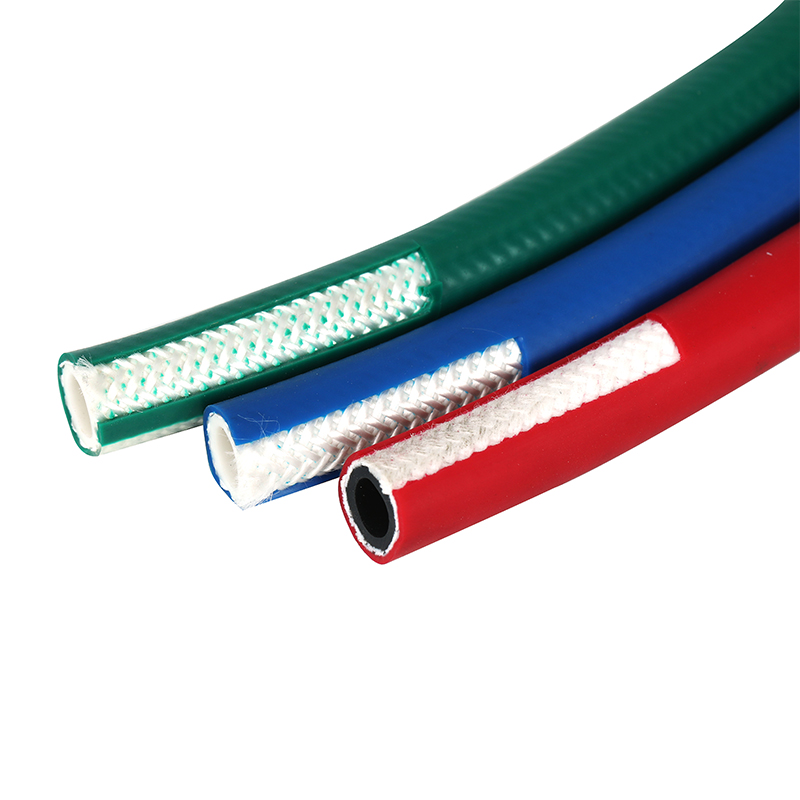

Transfer hoses are flexible tubes designed to transport fluids between different locations. They are constructed from a variety of materials, depending on the fluid being transferred. Common materials include rubber, PVC, and various composites, which can handle different temperatures, pressures, and chemical compositions.

The design of a transfer hose is critical for ensuring durability and reliability. Many hoses come with reinforcements, such as textile or steel braiding, to increase their strength and resistance to pressure surges. Additionally, the inner lining of the hose is often crafted to be resistant to the specific chemicals or materials being transferred, preventing degradation and leaks.

Applications of Transfer Hoses

The versatility of transfer hoses makes them indispensable in numerous sectors

1. Oil and Gas Industry In this sector, transfer hoses are used to move crude oil, refined petroleum products, and various other hydrocarbons. These hoses are designed to withstand high pressure and extreme temperatures, ensuring safe and efficient transfer.

transfer hose

2. Chemical Processing For transporting harmful or corrosive chemicals, specialized transfer hoses with chemical-resistant properties are essential. These hoses prevent any unwanted leaks that could contaminate the environment and pose safety risks.

3. Food and Beverage Food-grade transfer hoses are made with materials that comply with safety regulations. They ensure that liquids, such as milk, juices, and beer, are transferred without contamination, preserving taste and safety.

4. Agriculture In agriculture, transfer hoses are often used to transfer fertilizers and irrigation fluids. Their flexibility allows for ease of movement across various terrains.

5. Construction and Mining Here, hoses are utilized to transport slurries, water, and other materials necessary for operations, showcasing their robustness in challenging environments.

Maintenance and Safety Considerations

Proper maintenance of transfer hoses is crucial to avoid leaks and ensure safety. Regular inspection for signs of wear, such as cracks, bulges, or fraying, can help prevent catastrophic failures. It’s also important to follow the manufacturer’s guidelines regarding pressure ratings and the types of fluids that can be safely transferred through each hose.

Additionally, operators should utilize the appropriate fittings and couplings to ensure tight seals, preventing any leaks during transfer. Training personnel on proper handling techniques can further enhance safety.

In conclusion, transfer hoses are more than just simple tubes; they are vital components in fluid management across various industries. Understanding their construction, applications, and the importance of maintenance can significantly impact operational efficiency and safety. Whether you are in manufacturing, agriculture, or any sector involving fluid transport, ensuring the right transfer hose is used and maintained is essential for successful operations.

-

Top Quality Oxy Acetylene Hoses for Sale Fit for Welding DemandsNewsJul.28,2025

-

The Future of Pneumatic Air Tubes in IndustryNewsJul.28,2025

-

Superior and Reliable LPG Hose Pipe Solutions for Every NeedNewsJul.28,2025

-

Exceptionally Durable and Versatile Premium Braided PVC TubingNewsJul.28,2025

-

Best Adapters for Connecting Garden Hose to PVC Pipe ConnectionsNewsJul.28,2025

-

The Essential Role of LPG Hoses in Safe and Efficient Gas DistributionNewsJul.16,2025