Optimizing Transfer Hose Efficiency for Enhanced Fluid Management Solutions

Understanding Transfer Hoses The Essential Link in Fluid Management

Transfer hoses are crucial components in various industries, facilitating the movement of fluids from one location to another. These hoses are designed to handle a wide range of substances, including water, chemicals, and fuels, making them indispensable in applications such as agriculture, manufacturing, and construction. In this article, we will explore the significance of transfer hoses, their applications, and the factors to consider when selecting the right hose for your needs.

Importance of Transfer Hoses

The primary function of transfer hoses is to provide a safe and efficient means of transporting fluids. Industries rely on these hoses to minimize spills, leaks, and contamination, which can cause environmental hazards and safety concerns. A well-constructed transfer hose ensures the integrity of the fluid being transported, maintaining its chemical properties and preventing any adverse reactions.

Moreover, transfer hoses are engineered to withstand various environmental factors, including temperature fluctuations, pressure variations, and exposure to chemicals. This durability is essential for maintaining operational efficiency and reducing downtime caused by equipment failure.

Applications of Transfer Hoses

Transfer hoses are commonly used in diverse fields. In agriculture, they facilitate the irrigation process, allowing farmers to transport water directly from a source to their fields. This efficiency is crucial for crop production, especially in regions where water availability is limited.

In the petroleum and chemical industries, transfer hoses are utilized to move fuels, oils, and other hazardous substances safely. These hoses are often constructed with specialized materials that resist degradation and are compatible with the fluids being transported. For instance, rubber and PVC are common materials used, each offering unique advantages, such as flexibility and chemical resistance.

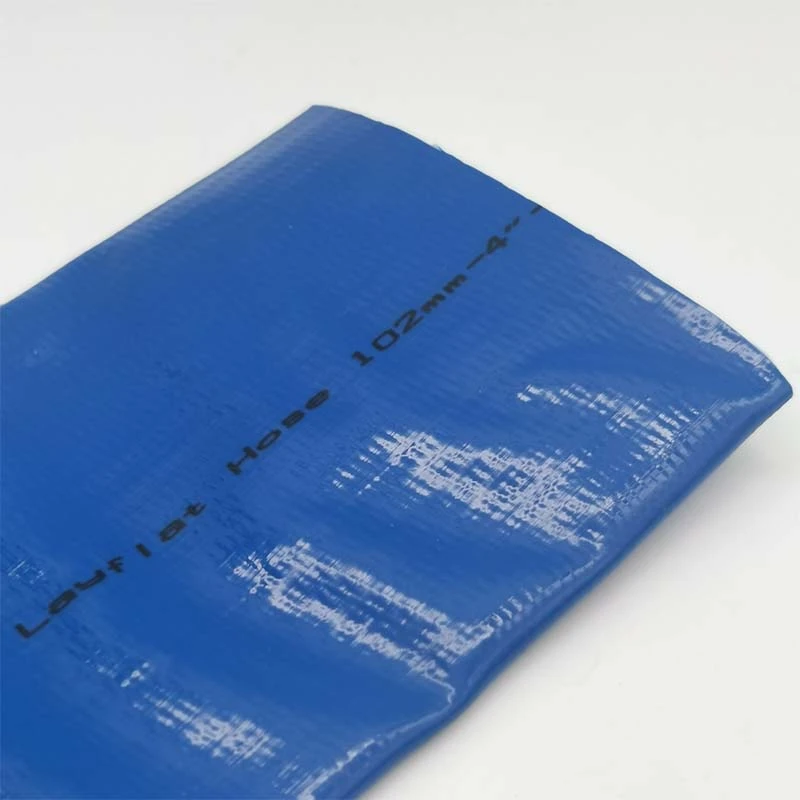

transfer hose

Additionally, transfer hoses are vital in construction sites, where they are used to deliver water, cement, and other materials. Their ability to transport heavy and viscous materials without compromising integrity is essential for effective project management.

Selecting the Right Transfer Hose

Choosing the appropriate transfer hose involves several considerations to ensure compatibility and safety. First, it is crucial to identify the type of fluid being transferred. Different materials and constructions are required for water, fuels, chemicals, or food-grade substances.

Secondly, the operating conditions must be evaluated. Factors such as temperature, pressure, and the environment in which the hose will be used play significant roles in determining the right hose material. For example, high-temperature applications may require hoses made from heat resistant materials, while corrosive chemicals may need hoses made from specialized compounds.

The diameter of the hose is another critical factor. A larger diameter typically allows for a greater flow rate, but it may also be heavier and less flexible. Conversely, a smaller diameter hose may be easier to maneuver but could restrict flow.

Finally, consider the length required for your application. Transfer hoses come in various lengths, and selecting the appropriate size ensures efficient fluid movement.

Conclusion

Transfer hoses are a vital part of fluid management across multiple industries. Their ability to safely and efficiently transport a variety of substances makes them indispensable for many applications. By understanding the importance, applications, and criteria for selecting transfer hoses, businesses can optimize their operations, ensure compliance with safety standards, and minimize environmental impact. Properly maintained transfer hoses will not only enhance productivity but also contribute to the overall success of fluid management strategies.

-

Welded Wire Mesh Panel: Durable, Versatile, and AffordableNewsJul.28,2025

-

Top Quality Oxy Acetylene Hoses for Sale Fit for Welding DemandsNewsJul.28,2025

-

The Future of Pneumatic Air Tubes in IndustryNewsJul.28,2025

-

Superior and Reliable LPG Hose Pipe Solutions for Every NeedNewsJul.28,2025

-

Exceptionally Durable and Versatile Premium Braided PVC TubingNewsJul.28,2025

-

Best Adapters for Connecting Garden Hose to PVC Pipe ConnectionsNewsJul.28,2025