Jul . 02, 2024 03:00

Back to list

Spiral PU Tubing A Flexible and Durable Solution for Various Industries

The Unfolding Marvel A Comprehensive Look at Spiral PU Tube Technology

In the realm of industrial piping systems, a revolutionary innovation has emerged - the Spiral Polyurethane (PU) Tube. This cutting-edge technology is reshaping the landscape of fluid transportation, offering unparalleled efficiency and durability compared to traditional pipe materials.

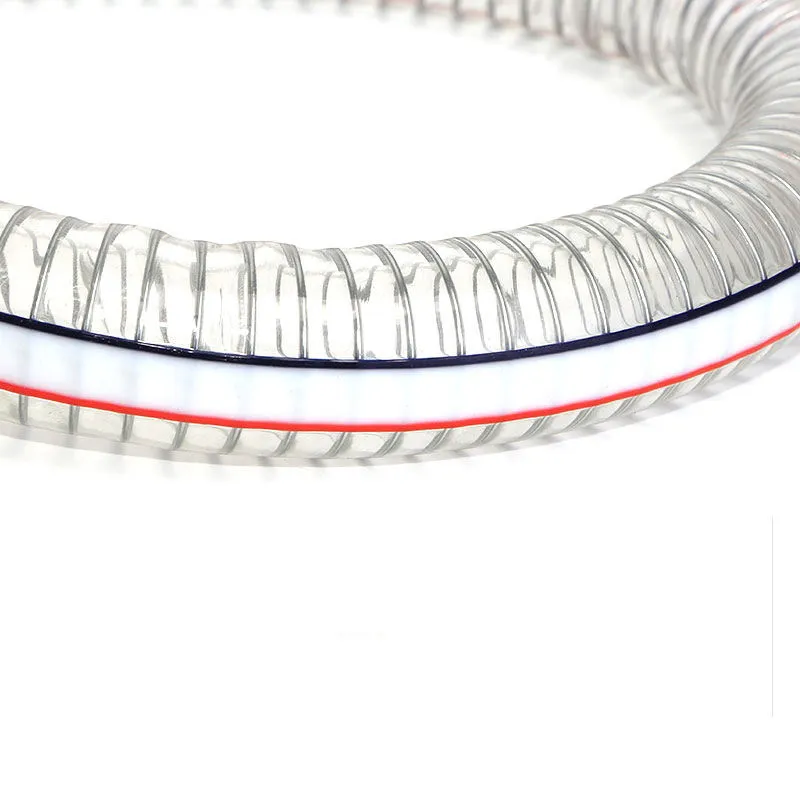

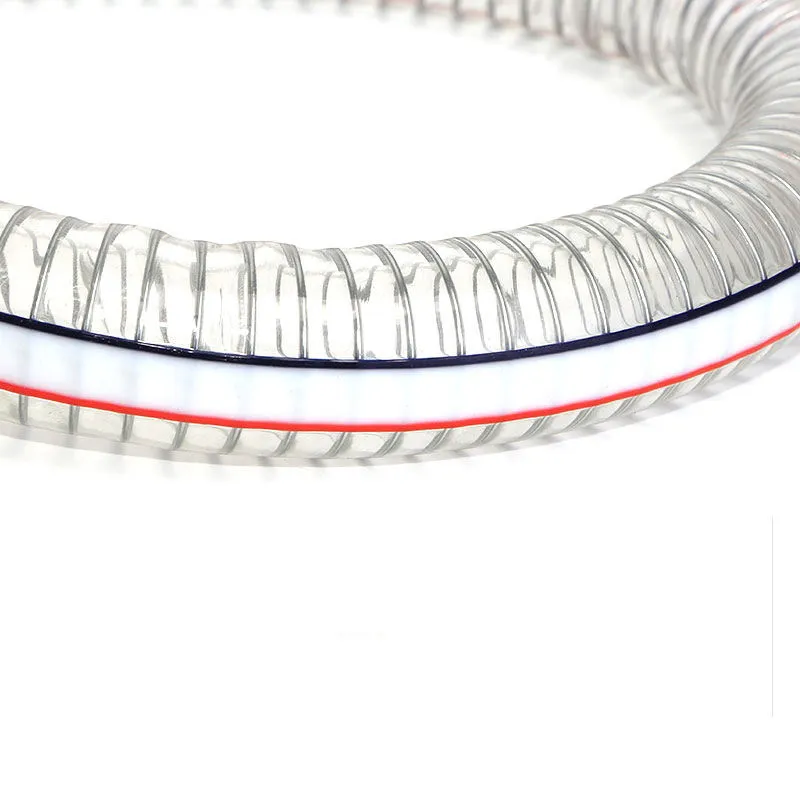

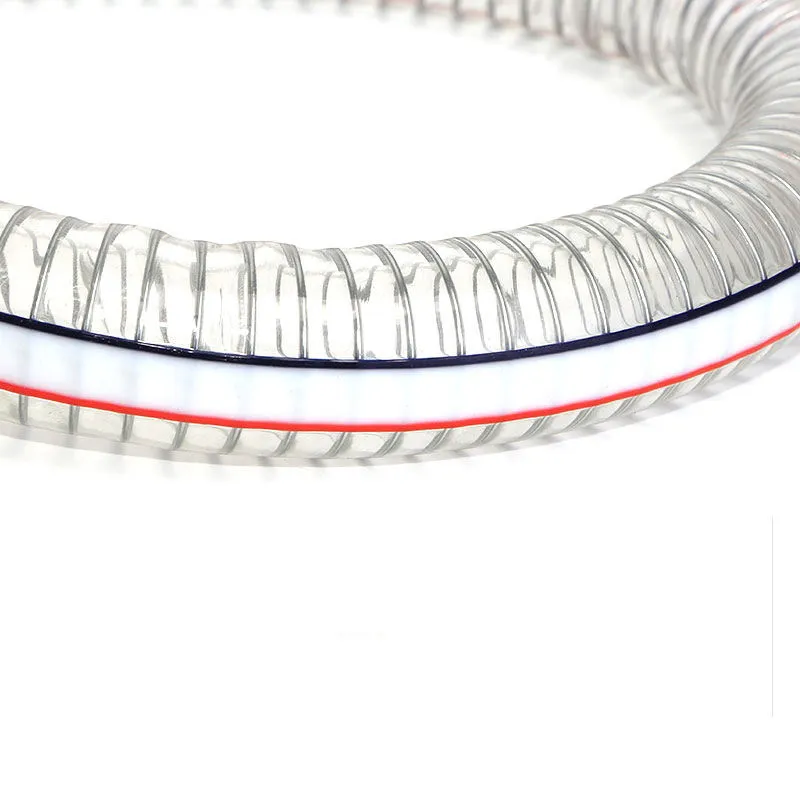

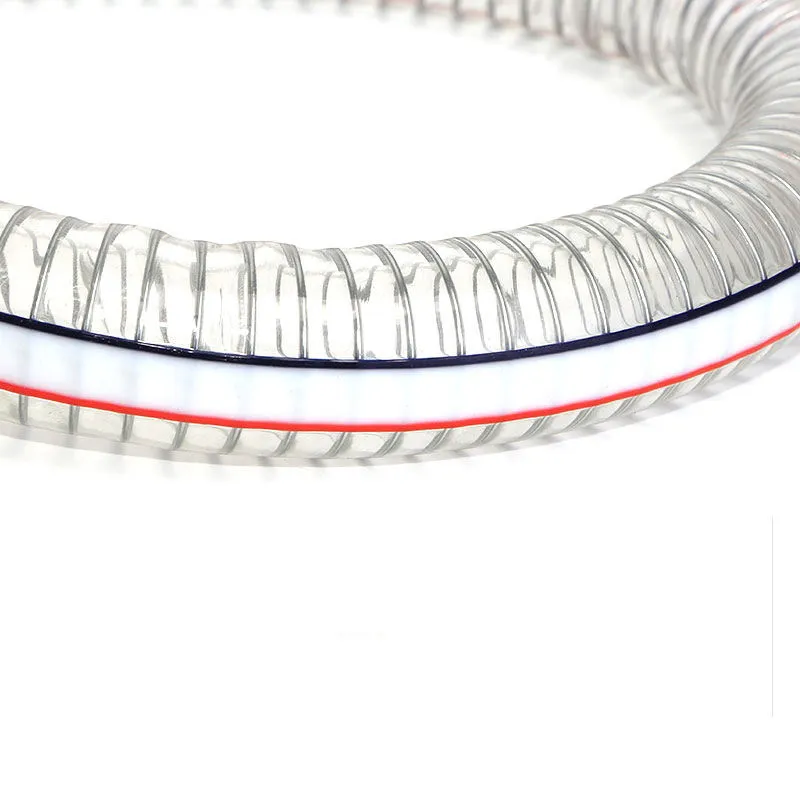

Polyurethane, a synthetic polymer known for its exceptional mechanical properties, forms the backbone of spiral PU tubes. The 'Spiral' in the name refers to the manufacturing process where the tube is wound in a helical pattern, providing it with unique structural integrity. This design not only enhances flexibility but also increases resistance against pressure and impact, making it ideal for various demanding applications.

The spiral configuration of these tubes allows for greater flexibility without compromising strength. It enables easy installation in tight spaces, reduces the risk of kinking, and adapts seamlessly to changes in direction. Moreover, the spiral design enhances flow dynamics, resulting in reduced fluid friction and improved overall system performance.

One of the standout features of spiral PU tubes is their remarkable abrasion resistance. This is particularly crucial in industries dealing with abrasive fluids or in environments with high wear and tear. Their robustness ensures a longer lifespan, reducing maintenance costs and downtime significantly.

Furthermore, these tubes exhibit excellent chemical resistance, capable of withstanding a wide range of corrosive substances

Furthermore, these tubes exhibit excellent chemical resistance, capable of withstanding a wide range of corrosive substances Furthermore, these tubes exhibit excellent chemical resistance, capable of withstanding a wide range of corrosive substances

Furthermore, these tubes exhibit excellent chemical resistance, capable of withstanding a wide range of corrosive substances

Furthermore, these tubes exhibit excellent chemical resistance, capable of withstanding a wide range of corrosive substances

Furthermore, these tubes exhibit excellent chemical resistance, capable of withstanding a wide range of corrosive substances spiral pu tube. They maintain their integrity in extreme temperatures, from sub-zero to moderate heat, making them suitable for both cryogenic and high-temperature applications.

In addition to these technical advantages, spiral PU tubes are also environmentally friendly. Their lightweight nature reduces transportation emissions, while their recyclability aligns with sustainability goals. They also have a lower carbon footprint compared to metal or PVC pipes due to their energy-efficient production process.

Despite their robustness, spiral PU tubes are surprisingly lightweight, which simplifies handling and installation. Their low weight-to-strength ratio makes them an attractive choice for applications where weight is a critical factor, such as in aerospace or automotive industries.

In conclusion, the spiral PU tube is a testament to the power of engineering innovation. Its unique design and superior material properties make it a game-changer in various sectors, from construction and manufacturing to agriculture and mining. As technology continues to evolve, we can anticipate even more advanced iterations of this remarkable piping solution, pushing the boundaries of efficiency and durability in fluid management systems.

spiral pu tube. They maintain their integrity in extreme temperatures, from sub-zero to moderate heat, making them suitable for both cryogenic and high-temperature applications.

In addition to these technical advantages, spiral PU tubes are also environmentally friendly. Their lightweight nature reduces transportation emissions, while their recyclability aligns with sustainability goals. They also have a lower carbon footprint compared to metal or PVC pipes due to their energy-efficient production process.

Despite their robustness, spiral PU tubes are surprisingly lightweight, which simplifies handling and installation. Their low weight-to-strength ratio makes them an attractive choice for applications where weight is a critical factor, such as in aerospace or automotive industries.

In conclusion, the spiral PU tube is a testament to the power of engineering innovation. Its unique design and superior material properties make it a game-changer in various sectors, from construction and manufacturing to agriculture and mining. As technology continues to evolve, we can anticipate even more advanced iterations of this remarkable piping solution, pushing the boundaries of efficiency and durability in fluid management systems.

Furthermore, these tubes exhibit excellent chemical resistance, capable of withstanding a wide range of corrosive substances

Furthermore, these tubes exhibit excellent chemical resistance, capable of withstanding a wide range of corrosive substances

Furthermore, these tubes exhibit excellent chemical resistance, capable of withstanding a wide range of corrosive substances

Furthermore, these tubes exhibit excellent chemical resistance, capable of withstanding a wide range of corrosive substances spiral pu tube. They maintain their integrity in extreme temperatures, from sub-zero to moderate heat, making them suitable for both cryogenic and high-temperature applications.

In addition to these technical advantages, spiral PU tubes are also environmentally friendly. Their lightweight nature reduces transportation emissions, while their recyclability aligns with sustainability goals. They also have a lower carbon footprint compared to metal or PVC pipes due to their energy-efficient production process.

Despite their robustness, spiral PU tubes are surprisingly lightweight, which simplifies handling and installation. Their low weight-to-strength ratio makes them an attractive choice for applications where weight is a critical factor, such as in aerospace or automotive industries.

In conclusion, the spiral PU tube is a testament to the power of engineering innovation. Its unique design and superior material properties make it a game-changer in various sectors, from construction and manufacturing to agriculture and mining. As technology continues to evolve, we can anticipate even more advanced iterations of this remarkable piping solution, pushing the boundaries of efficiency and durability in fluid management systems.

spiral pu tube. They maintain their integrity in extreme temperatures, from sub-zero to moderate heat, making them suitable for both cryogenic and high-temperature applications.

In addition to these technical advantages, spiral PU tubes are also environmentally friendly. Their lightweight nature reduces transportation emissions, while their recyclability aligns with sustainability goals. They also have a lower carbon footprint compared to metal or PVC pipes due to their energy-efficient production process.

Despite their robustness, spiral PU tubes are surprisingly lightweight, which simplifies handling and installation. Their low weight-to-strength ratio makes them an attractive choice for applications where weight is a critical factor, such as in aerospace or automotive industries.

In conclusion, the spiral PU tube is a testament to the power of engineering innovation. Its unique design and superior material properties make it a game-changer in various sectors, from construction and manufacturing to agriculture and mining. As technology continues to evolve, we can anticipate even more advanced iterations of this remarkable piping solution, pushing the boundaries of efficiency and durability in fluid management systems. Latest news

-

Welded Wire Mesh Panel: Durable, Versatile, and AffordableNewsJul.28,2025

-

Top Quality Oxy Acetylene Hoses for Sale Fit for Welding DemandsNewsJul.28,2025

-

The Future of Pneumatic Air Tubes in IndustryNewsJul.28,2025

-

Superior and Reliable LPG Hose Pipe Solutions for Every NeedNewsJul.28,2025

-

Exceptionally Durable and Versatile Premium Braided PVC TubingNewsJul.28,2025

-

Best Adapters for Connecting Garden Hose to PVC Pipe ConnectionsNewsJul.28,2025

HOT PRODUCT

Provide You The Highest Quality Work

INQUIRE