Durable Reinforced Polyurethane Tubing for Versatile Industrial Applications and Enhanced Performance

Reinforced Polyurethane Hose A Comprehensive Overview

Reinforced polyurethane hoses have rapidly become a staple in a multitude of industrial applications due to their impressive balance of flexibility, durability, and resistance to wear. As industries diversify and innovate, the demand for high-performing materials continues to grow. This article delves into the essential characteristics, applications, and advantages of reinforced polyurethane hoses, highlighting why they are favored over traditional materials.

What is Reinforced Polyurethane Hose?

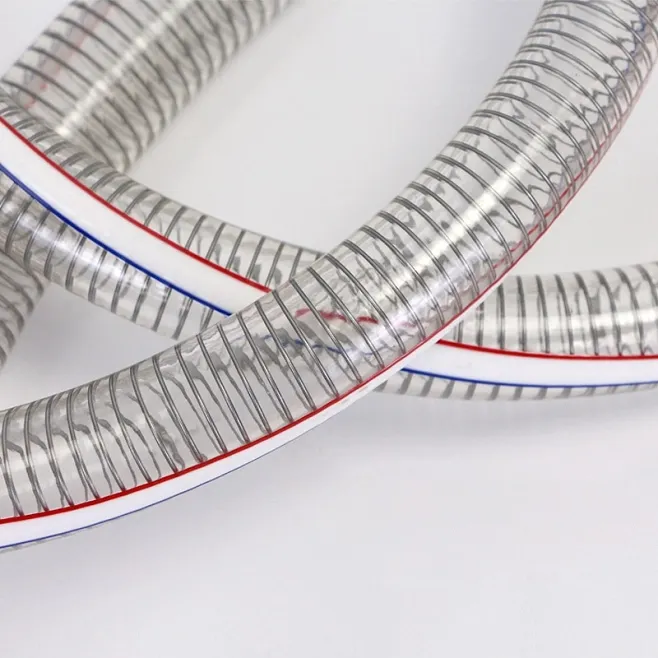

Reinforced polyurethane hoses are flexible tubes made from polyurethane, which is a versatile polymer that can be tailored to meet specific performance criteria. These hoses are often reinforced with an internal layer of fabric or steel wire, which enhances their strength and structural integrity. The combination of polyurethane with reinforcement allows these hoses to withstand higher pressures and temperatures, making them suitable for demanding environments.

Key Characteristics

1. Flexibility and Lightweight One of the most notable features of reinforced polyurethane hoses is their extraordinary flexibility. They can be easily maneuvered around machinery and equipment without crimping or kinking. Additionally, their lightweight nature makes installation and handling more efficient compared to heavier hose materials.

2. Durability The reinforced structure of these hoses grants them excellent durability, allowing them to resist abrasion, cuts, and tears. This durability is essential in harsh environments where hoses might encounter sharp edges or rough surfaces.

3. Chemical Resistance Reinforced polyurethane hoses demonstrate commendable resistance to a wide range of chemicals and solvents. This characteristic enables them to be used in applications involving chemicals crucial for various industries, such as agricultural, manufacturing, and construction sectors.

4. Temperature Resistance These hoses can typically handle a broad range of temperatures, often from -40°F to 160°F (-40°C to 70°C), allowing them to be used in both cold and hot environments without losing shape or functionality.

Applications

reinforced polyurethane hose

Reinforced polyurethane hoses are versatile and can be found in

- Air and Water Transfer Widely used for transferring air and water in both residential and industrial applications. Their flexibility and durability make them ideal for various pumping and irrigation systems.

- Automotive Industry Used for coolant lines, fuel lines, and various other applications due to their ability to withstand temperature fluctuations and chemical exposure.

- Manufacturing and Construction Essential in pneumatic systems, handling materials, and in conveying systems. Their resistance to wear and tear makes them suitable for rigorous manufacturing environments.

- Food and Beverage Industry Some reinforced polyurethane hoses are FDA-compliant, making them suitable for food and beverage transfer, ensuring safety without compromising quality.

- Mining and Drilling Their robust nature makes them suitable for demanding applications such as transporting slurry, air, or water in mining operations.

Advantages Over Traditional Materials

Reinforced polyurethane hoses offer numerous advantages over traditional rubber or PVC hoses. They tend to have a longer service life, require less maintenance, and can handle higher pressures and temperatures. Unlike rubber hoses, which may degrade and crack over time, polyurethane maintains its integrity even under strenuous conditions. Additionally, the resistance to chemicals and UV light makes them suitable for outdoor applications without worrying about degradation.

Conclusion

In summary, reinforced polyurethane hoses represent a pivotal innovation in the hose industry, bringing together an array of features that cater to a wide range of applications. Their unique blend of flexibility, durability, and resistance to adverse conditions positions them as a superior choice over traditional hoses. As industries continue to evolve, the reliance on such advanced materials will likely increase, ensuring that reinforced polyurethane hoses remain at the forefront of industrial solutions. Whether for the automotive industry or demanding construction applications, these hoses provide a reliable and efficient solution that meets the stringent requirements of modern engineering and manufacturing.

-

Top Quality Oxy Acetylene Hoses for Sale Fit for Welding DemandsNewsJul.28,2025

-

The Future of Pneumatic Air Tubes in IndustryNewsJul.28,2025

-

Superior and Reliable LPG Hose Pipe Solutions for Every NeedNewsJul.28,2025

-

Exceptionally Durable and Versatile Premium Braided PVC TubingNewsJul.28,2025

-

Best Adapters for Connecting Garden Hose to PVC Pipe ConnectionsNewsJul.28,2025

-

The Essential Role of LPG Hoses in Safe and Efficient Gas DistributionNewsJul.16,2025