pvc suction pipe manufacturers

PVC Suction Pipe Manufacturers An Overview

Polyvinyl chloride (PVC) suction pipes play a critical role in various industrial and agricultural applications. Known for their durability, flexibility, and resistance to chemicals, these pipes are widely utilized in water transport systems, drainage, and irrigation projects. As the demand for efficient water utilization grows, the role of PVC suction pipe manufacturers becomes increasingly significant.

Understanding PVC Suction Pipes

PVC suction pipes are specifically designed to handle the suction process effectively. These pipes are typically used in scenarios where water must be moved from a lower elevation to a higher one, such as in pumping stations, aquaculture, and irrigation systems. The inherent properties of PVC—such as lightweight nature, corrosion resistance, and seamless installation—make these pipes an ideal choice for a multitude of applications.

The Manufacturing Process

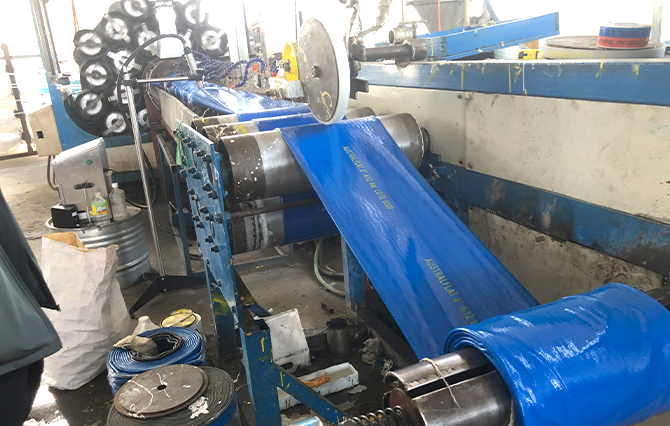

The production of PVC suction pipes involves a meticulous process. Initially, raw PVC resin is mixed with additives to enhance its physical properties and performance characteristics. These additives may include stabilizers, impact modifiers, and lubricants that improve processing capabilities.

The homogenized material is then fed into an extrusion machine, where it is heated and forced through a die to create a long, continuous pipe shape. The resulting pipe is cooled and cut into manageable lengths. Quality control measures are crucial during this stage, ensuring that the pipes meet required specifications for thickness, diameter, and pressure ratings. Post-production, the pipes may undergo a series of tests to evaluate their tensile strength, flexibility, and resistance to environmental stressors.

The Role of Manufacturers

Manufacturers of PVC suction pipes are tasked with adhering to strict industry standards and certifications. This ensures that the products they produce can withstand the rigors of various applications while maintaining safety and reliability. Leading manufacturers invest in advanced technology, employing state-of-the-art machinery and processes to enhance production efficiency.

pvc suction pipe manufacturers

Furthermore, manufacturers often provide customized solutions to meet specific customer requirements. This can include varying pipe diameters, lengths, and pressure ratings. Collaboration with engineers and architects is common, ensuring that the products designed and delivered align with system needs.

Key Players in the Market

The global market for PVC suction pipes features a mix of well-established companies and emerging players. Leading manufacturers often benefit from economies of scale, enabling them to offer competitive pricing while maintaining high-quality standards. Industry giants invest in research and development, pushing the boundaries of design and functionality in an effort to innovate and create superior products.

In addition to product quality, customer service plays a crucial role in the reputation of PVC suction pipe manufacturers. Timely delivery, responsive support, and effective communication can greatly enhance business relationships, often translating to repeat business and referrals.

Environmental Considerations

As the world increasingly shifts focus towards sustainability, PVC suction pipe manufacturers are also addressing environmental concerns. Many companies are adopting eco-friendly manufacturing practices, utilizing recyclable materials and minimizing waste. There is a growing emphasis on developing products that are not just effective but also environmentally responsible.

Additionally, manufacturers are exploring the production of bio-based PVC, which can provide similar performance characteristics while reducing reliance on fossil fuels. Such innovations reflect a commitment to sustainability, aligning the industry with modern environmental expectations.

Conclusion

PVC suction pipe manufacturers play an essential role in a variety of industries, supplying crucial infrastructure components that facilitate the efficient movement of water. With advancements in manufacturing processes, a commitment to quality, and a focus on sustainability, these manufacturers are well-equipped to meet the evolving demands of the market. As we look towards a future of responsible resource management and environmental stewardship, the role of PVC suction pipes in supporting these goals continues to be significant. Investing in high-quality products from reputable manufacturers is vital for ensuring system efficiency and longevity, ultimately contributing to the sustainability of water management practices globally.

-

Welded Wire Mesh Panel: Durable, Versatile, and AffordableNewsJul.28,2025

-

Top Quality Oxy Acetylene Hoses for Sale Fit for Welding DemandsNewsJul.28,2025

-

The Future of Pneumatic Air Tubes in IndustryNewsJul.28,2025

-

Superior and Reliable LPG Hose Pipe Solutions for Every NeedNewsJul.28,2025

-

Exceptionally Durable and Versatile Premium Braided PVC TubingNewsJul.28,2025

-

Best Adapters for Connecting Garden Hose to PVC Pipe ConnectionsNewsJul.28,2025