PVC Suction Hoses for Efficient Fluid Transportation and Industrial Use

Understanding PVC Suction Hoses Applications, Benefits, and Maintenance

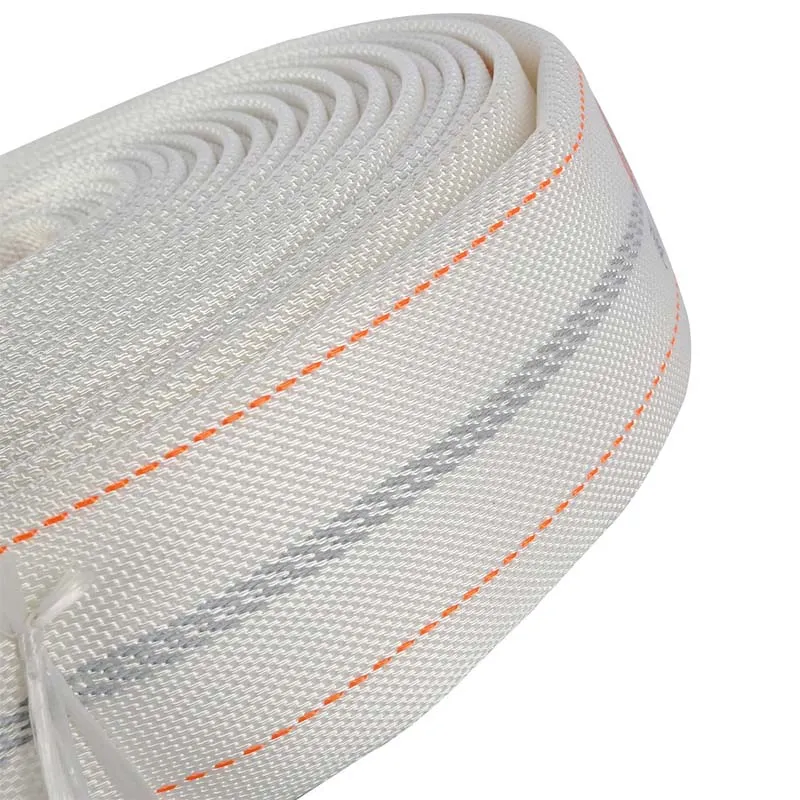

PVC (Polyvinyl Chloride) suction hoses are essential equipment in numerous industries, including agriculture, construction, and manufacturing. These versatile hoses are designed to transport fluids, particularly liquids, from one point to another, facilitating efficient and effective operations. This article explores the various applications of PVC suction hoses, their advantages, and essential maintenance tips.

Applications of PVC Suction Hoses

PVC suction hoses are widely used across different sectors due to their flexibility and resistance to chemicals. One of the most common applications is in agricultural settings, where they are utilized for irrigation and drainage purposes. Farmers use these hoses to draw water from wells or reservoirs and distribute it across fields, promoting better crop yields.

In construction, PVC suction hoses are often employed in pumping systems to remove water from excavated sites or basements. Their lightweight and flexible nature makes them easy to handle, allowing workers to maneuver them into tight spaces where traditional pipes might not fit. Moreover, these hoses are commonly used in industrial applications for transferring various liquids, including wastewater and chemicals.

Advantages of PVC Suction Hoses

1. Durability PVC suction hoses are known for their long-lasting nature. They are resistant to abrasion, weather conditions, and chemicals, making them suitable for both indoor and outdoor use.

2. Flexibility One of the notable features of PVC hoses is their flexibility. They can bend and twist without breaking, which is crucial for applications requiring the hose to navigate around obstacles.

3. Lightweight PVC hoses are considerably lighter than metal or rubber alternatives. This makes them easier to transport and handle, reducing the strain on workers during installation and maintenance.

4. Cost-Effective Compared to other materials, PVC is relatively inexpensive. This affordability makes PVC suction hoses an attractive option for businesses looking to optimize their operational costs without compromising on quality.

pvc suction hoses

5. Variety of Sizes and Configurations PVC suction hoses come in various diameters and lengths, ensuring that users can find the perfect fit for their specific needs. Whether it’s for a small agricultural application or a large industrial operation, there’s likely a suitable option available.

Maintenance of PVC Suction Hoses

To ensure the longevity and efficiency of PVC suction hoses, proper maintenance is crucial. Here are some essential tips

1. Regular Inspections Periodically check hoses for signs of wear and tear, such as cracks, leaks, or bulges. Early detection of issues can prevent more significant problems down the line.

2. Proper Storage When not in use, store PVC hoses in a cool, dry place, away from direct sunlight. Prolonged exposure to UV rays can lead to degradation of the material over time.

3. Cleaning After each use, especially in applications involving chemicals or muddy water, thoroughly clean the hoses to prevent build-up and contamination. Use a mild detergent and rinse with clean water.

4. Avoiding Kinks and Bends When using the hose, ensure that it is not kinked or sharply bent, as this can restrict fluid flow and damage the internal structure of the hose.

5. Check Connections Ensure that all fittings and connections are secure and leak-free. Loose connections can lead to fluid loss and affect overall performance.

Conclusion

PVC suction hoses are indispensable tools across various industries, providing efficient solutions for fluid transport. Their durability, flexibility, and cost-effectiveness make them a popular choice among professionals. By understanding their applications, benefits, and maintenance requirements, users can maximize the lifespan and efficiency of these versatile hoses, ultimately contributing to the success of their operations.

-

Welded Wire Mesh Panel: Durable, Versatile, and AffordableNewsJul.28,2025

-

Top Quality Oxy Acetylene Hoses for Sale Fit for Welding DemandsNewsJul.28,2025

-

The Future of Pneumatic Air Tubes in IndustryNewsJul.28,2025

-

Superior and Reliable LPG Hose Pipe Solutions for Every NeedNewsJul.28,2025

-

Exceptionally Durable and Versatile Premium Braided PVC TubingNewsJul.28,2025

-

Best Adapters for Connecting Garden Hose to PVC Pipe ConnectionsNewsJul.28,2025