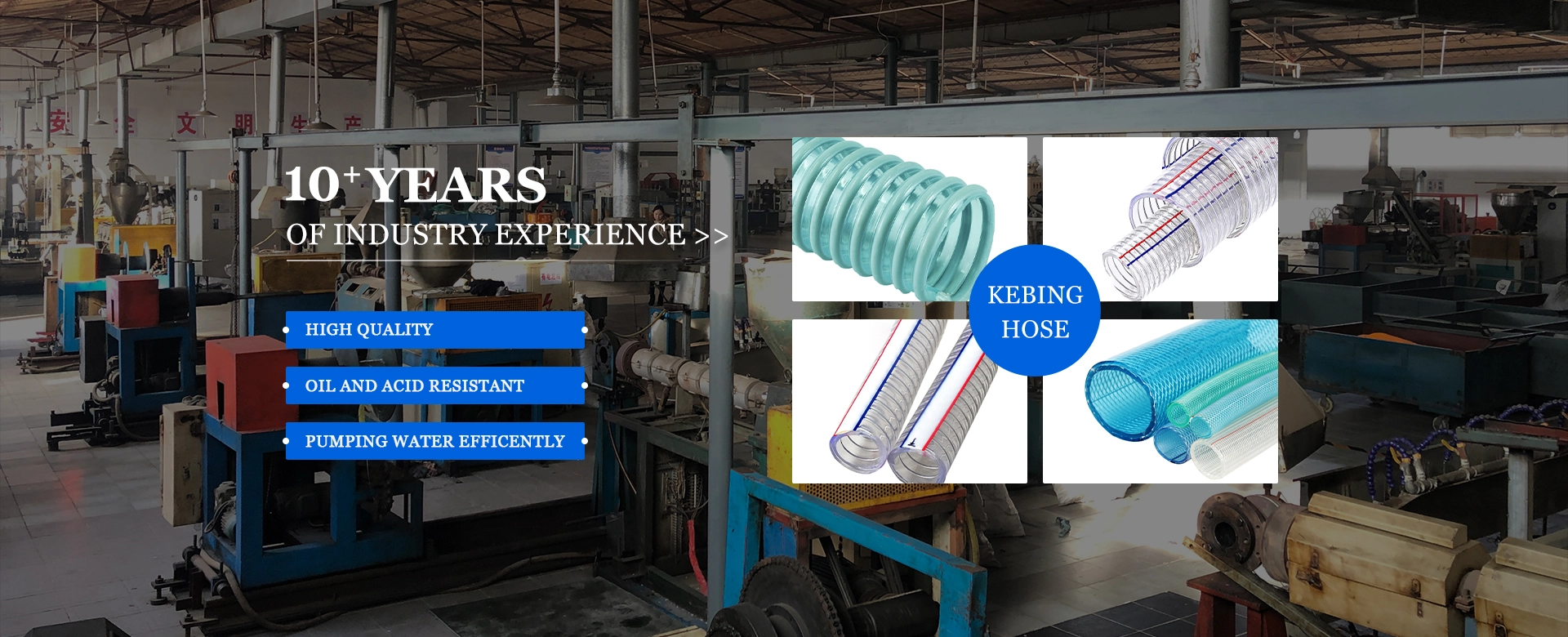

Durable PVC Steel Wire Hose for Enhanced Flexibility and Strength

The Versatility and Benefits of PVC Steel Wire Hose

In the realm of industrial and domestic applications, hoses play a vital role in fluid transportation. Among the various types available in the market, the PVC steel wire hose stands out for its robust construction and versatility. This article explores the benefits, applications, and unique features of PVC steel wire hoses, illuminating why they have become a preferred choice across many industries.

What is PVC Steel Wire Hose?

PVC (Polyvinyl Chloride) steel wire hose is a type of reinforced hose made with a durable PVC outer layer and embedded steel wire spirals. This combination not only enhances its structural integrity but also allows it to maintain a level of flexibility for easy handling. The steel wire reinforcement provides additional strength, enabling the hose to withstand high pressures and tough working conditions.

Key Advantages

1. Durability The primary advantage of PVC steel wire hoses is their exceptional durability. They resist wear and tear, making them ideal for environments where high abrasiveness is a concern. The steel wire reinforcement protects the hose from kinking, bending, and crushing, ensuring longevity and reliability.

2. Pressure Resistance These hoses are designed to handle high pressure, which is crucial for many applications. Whether in agricultural irrigation or industrial fluid transport, the ability to maintain structure under pressure ensures consistent performance.

3. Flexibility Despite their strength, PVC steel wire hoses are surprisingly flexible. This flexibility makes them easy to maneuver in tight spaces and ensures they can be used effectively in a variety of settings, which is particularly beneficial in construction and agriculture.

4. Chemical Resistance PVC itself is known for its resistance to many chemicals, making PVC steel wire hoses suitable for transporting a wide range of liquids. They can handle water, oils, and various types of chemicals, contributing to their broad applicability.

5. Cost-Effective Compared to rubber hoses, PVC steel wire hoses are often more affordable while still offering superior performance. This cost-effectiveness makes them a popular choice for businesses looking to minimize expenses without sacrificing quality.

pvc steel wire hose

Applications

The versatility of PVC steel wire hoses enables them to be employed in various applications across multiple sectors

- Agriculture In agricultural settings, these hoses are commonly used for irrigation, conveying water to crops efficiently. Their durability ensures they hold up well against harsh environmental conditions.

- Construction PVC steel wire hoses are frequently utilized on construction sites for pumping liquids, transporting sand, and managing water flow. Their ability to endure high pressure and physical stress makes them ideal for demanding tasks.

- Industrial Use In industrial settings, these hoses are employed in conveying chemicals, air, and other materials. Their robust design caters to the needs of factories and manufacturing plants, where reliability is paramount.

- Marine Applications The flexibility and chemical resistance of PVC steel wire hoses make them suitable for marine applications, including sewerage and bilge pumping.

Maintenance and Care

To ensure the longevity of PVC steel wire hoses, proper maintenance is crucial. Users should regularly inspect hoses for signs of wear, such as cracks or abrasions, and ensure they are stored properly to avoid damage from UV exposure or extreme temperatures. Cleaning the hoses after use can also help maintain their integrity, especially after transporting chemicals or viscous liquids.

Conclusion

In conclusion, PVC steel wire hoses provide an exceptional blend of strength, flexibility, and cost-effectiveness, making them an ideal choice for a wide range of applications. Their durability and pressure-resistance capabilities ensure reliable performance whether on a construction site, in agricultural use, or any other demanding scenario. By choosing PVC steel wire hoses, industries can benefit from enhanced productivity and reduced maintenance costs, solidifying the hose's place as a staple in fluid transportation solutions. As technology advances, further innovations in design and materials may continue to enhance the performance of these incredible hoses, paving the way for even broader applications in the future.

-

Top Quality Oxy Acetylene Hoses for Sale Fit for Welding DemandsNewsJul.28,2025

-

The Future of Pneumatic Air Tubes in IndustryNewsJul.28,2025

-

Superior and Reliable LPG Hose Pipe Solutions for Every NeedNewsJul.28,2025

-

Exceptionally Durable and Versatile Premium Braided PVC TubingNewsJul.28,2025

-

Best Adapters for Connecting Garden Hose to PVC Pipe ConnectionsNewsJul.28,2025

-

The Essential Role of LPG Hoses in Safe and Efficient Gas DistributionNewsJul.16,2025