pu tube manufacturers

The Evolution and Importance of PU Tube Manufacturers

Polyurethane (PU) tubes have become integral components in various industries, from automotive to healthcare, due to their versatility, durability, and flexibility. The demand for high-quality PU tubes has led to the emergence of specialized manufacturers, contributing significantly to advancements in material technology and engineering.

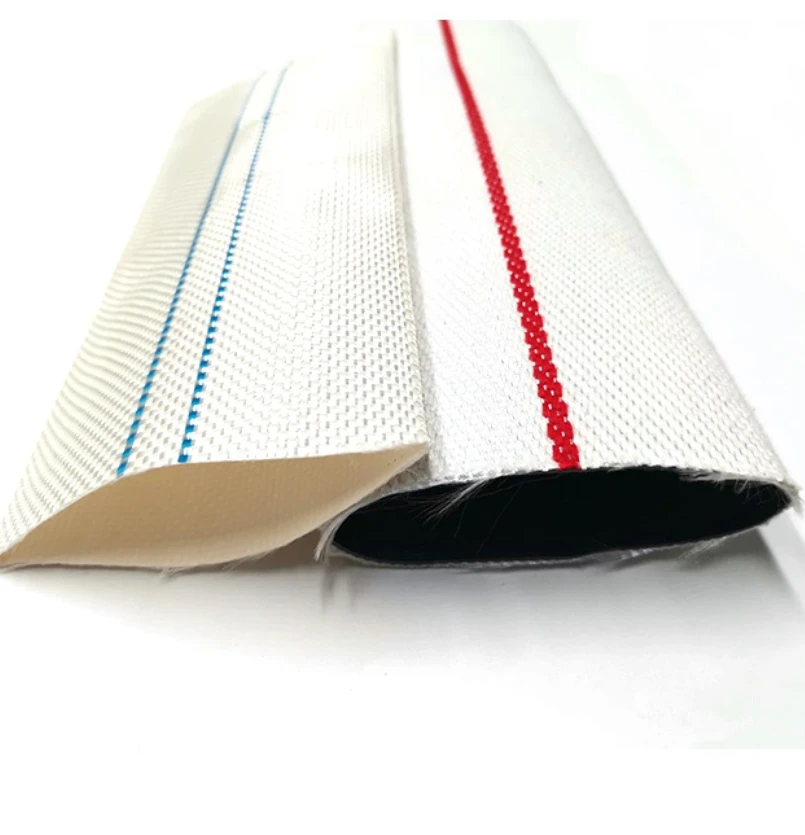

Understanding Polyurethane Tubes

Polyurethane is a polymer composed of organic units joined by carbamate (urethane) links. It is known for its remarkable properties such as elasticity, resilience, and resistance to abrasion and chemicals. These qualities make PU tubes suitable for a wide range of applications. Unlike traditional rubber or plastic tubes, PU tubes offer superior performance in extreme conditions, making them preferable for industries requiring robust and reliable solutions.

The Role of PU Tube Manufacturers

PU tube manufacturers play a pivotal role in ensuring the quality and performance of these products. They specialize in the design, production, and distribution of PU tubes, using advanced technologies and methods to meet the diverse needs of their clients. These manufacturers are at the forefront of innovation, constantly developing new formulations and production techniques to enhance the properties of PU tubes.

1. Customization and Quality Control

One of the key advantages of working with specialized PU tube manufacturers is the ability to customize products. Different industries may require tubes of varying sizes, thicknesses, and chemical resistances. Manufacturers can tailor their offerings to meet specific customer specifications, ensuring that the final product is fit for purpose. Quality control is another critical aspect; manufacturers implement rigorous testing procedures to ensure that every tube meets the necessary standards for safety and performance.

2. Sustainability Considerations

In recent years, there has been a growing emphasis on sustainability within manufacturing processes. PU tube manufacturers are increasingly adopting eco-friendly practices, such as using recyclable materials and reducing waste during production. This focus on sustainability not only appeals to environmentally conscious consumers but also positions companies favorably in an increasingly competitive marketplace.

pu tube manufacturers

3. Technological Advancements

The PU tube manufacturing industry has also benefited from technological advancements. The introduction of automation and sophisticated manufacturing equipment has enhanced production efficiency and accuracy. Manufacturers are now able to produce high volumes of PU tubes with consistent quality, reducing lead times and overall costs. Additionally, innovations in material formulations have led to the creation of PU tubes with enhanced properties, such as improved resistance to UV light and extreme temperatures.

Applications of PU Tubes

PU tubes are used in various applications across multiple sectors

- Automotive Industry In the automotive sector, PU tubes are utilized for fuel lines, air conditioning systems, and hydraulic lines due to their durability and resistance to high temperatures. - Medical Applications PU tubes are essential in the medical field, used for catheters and various medical devices, owing to their flexibility and biocompatibility. - Industrial Uses In industries such as construction and manufacturing, PU tubes are employed in pneumatic systems, conveying fluids, and transporting materials, highlighting their versatility.

Future Trends in PU Tube Manufacturing

Looking forward, the PU tube manufacturing industry is likely to witness continued growth driven by technological advancements and an increasing range of applications. Manufacturers will need to stay abreast of new technologies and market trends to remain competitive. The integration of smart technologies, such as IoT in monitoring tube performance and condition, may become more prevalent, enhancing product reliability and customer satisfaction.

Conclusion

PU tube manufacturers are vital to the supply chain of numerous industries, providing products that are essential for modern applications. As the demand for PU tubes continues to grow, manufacturers will be challenged to innovate and adapt to changing market dynamics. Their focus on customization, quality, and sustainability will be crucial in shaping the future of PU tube manufacturing and ensuring that industries have access to the reliable materials they need to thrive.

-

Top Quality Oxy Acetylene Hoses for Sale Fit for Welding DemandsNewsJul.28,2025

-

The Future of Pneumatic Air Tubes in IndustryNewsJul.28,2025

-

Superior and Reliable LPG Hose Pipe Solutions for Every NeedNewsJul.28,2025

-

Exceptionally Durable and Versatile Premium Braided PVC TubingNewsJul.28,2025

-

Best Adapters for Connecting Garden Hose to PVC Pipe ConnectionsNewsJul.28,2025

-

The Essential Role of LPG Hoses in Safe and Efficient Gas DistributionNewsJul.16,2025