pu tube 8mm

Understanding PU Tube 8mm Applications and Benefits

In the world of manufacturing and industrial applications, the choice of materials and components plays a pivotal role in determining efficiency, performance, and durability. Among the various options available, PU tubes, particularly those with an 8mm diameter, have gained significant attention due to their versatility and excellent properties. This article will explore what PU tubes are, their applications, and the benefits they offer.

What is a PU Tube?

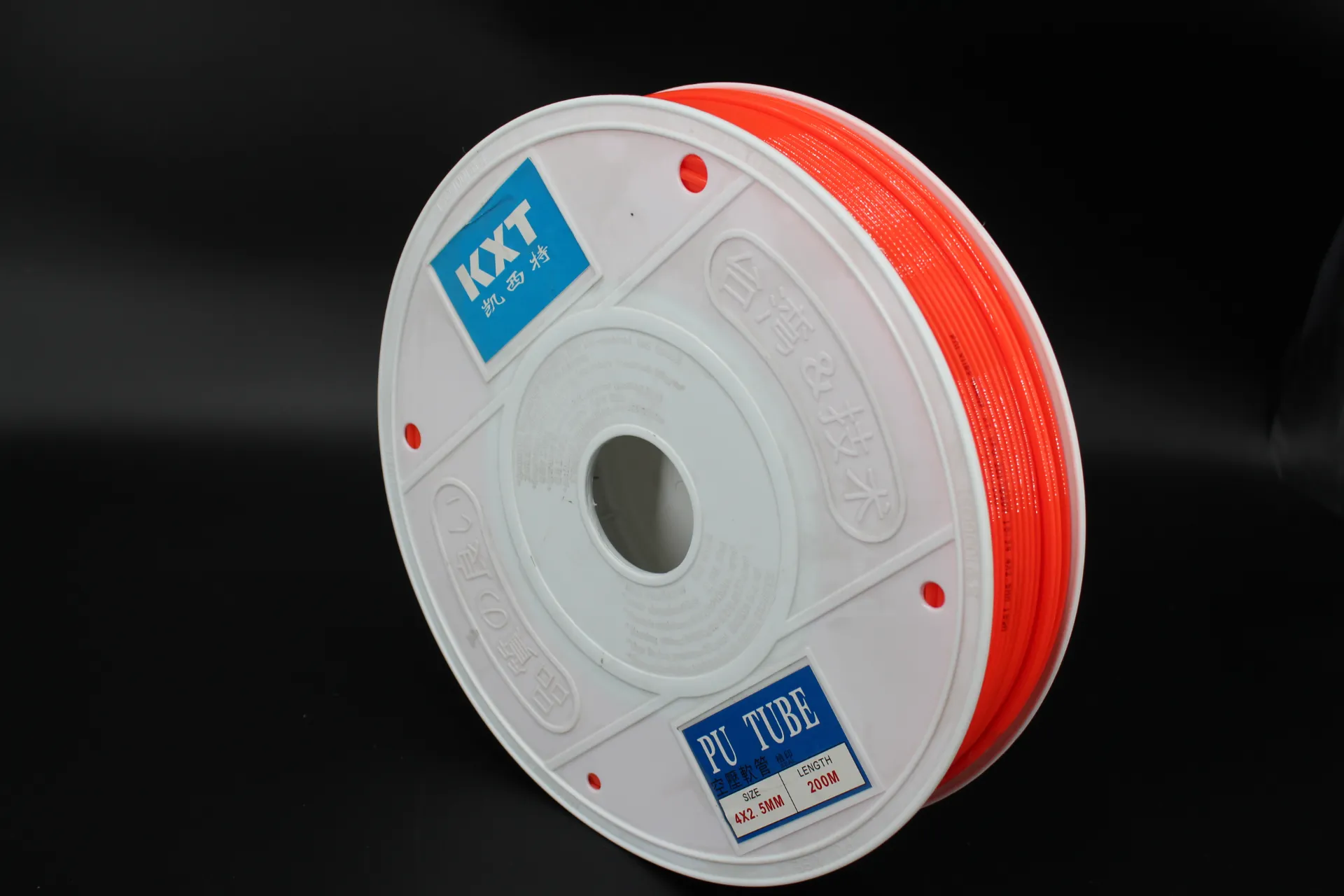

A PU tube, made from polyurethane, is a flexible, durable, and lightweight tube that can be used in a variety of applications. Polyurethane itself is a type of polymer that is known for its resilience, abrasion resistance, and flexibility. PU tubes can be manufactured in various diameters and wall thicknesses to suit specific requirements. The 8mm diameter tube is one of the popular sizes, offering a perfect balance between flexibility and strength.

Applications of PU Tube 8mm

1. Pneumatic Systems One of the most common applications for PU tubes is in pneumatic systems. They are used to transport air, providing the necessary pressure for components such as cylinders, valves, and actuators. The flexibility of the PU tube allows for easy routing in tight spaces, making it ideal for complex systems.

2. Hydraulic Systems Although less common than pneumatic applications, PU tubes can also be found in hydraulic systems, especially those that require lightweight and resistant hoses. Their ability to withstand pressure without compromising performance is crucial in hydraulic applications.

3. Automotive Industry In the automotive sector, PU tubes are utilized for fuel and oil delivery, as well as for coolant systems. Their resistance to various chemicals and temperatures makes them a reliable choice for automotive applications where durability is essential.

4. Medical Devices In the medical field, PU tubes are used in various devices and equipment, such as catheters and IV lines. Their biocompatibility and flexibility provide a safe and effective solution for transporting fluids in healthcare settings.

5. Food and Beverage Industry PU tubes meet food safety standards and are used in the transportation of food liquids and ingredients. Their ability to withstand cleaning processes and resist contamination makes them suitable for food and beverage applications.

pu tube 8mm

6. Electronics and Telecommunications Particularly in the production of wires and cables, PU tubes provide insulation and protection. They help safeguard sensitive electronic components from mechanical damage and environmental factors.

Advantages of PU Tube 8mm

1. Flexibility One of the key benefits of PU tubes is their high degree of flexibility. This property allows for easy installation and routing in various configurations without the risk of kinking or collapsing.

2. Durability PU tubes are known for their outstanding wear and tear resistance. They can withstand abrasions, impacts, and harsh environmental conditions, making them a long-lasting choice in demanding applications.

3. Chemical Resistance Polyurethane's inherent chemical resistance allows PU tubes to be used in applications where they might be exposed to oils, fuels, and other corrosive substances without degrading.

4. Lightweight Compared to metal or other heavy materials, PU tubes are lightweight, which contributes to energy savings in transportation and reduces the overall weight of systems.

5. Temperature Resistance PU tubes can operate effectively in a wide range of temperatures, making them suitable for both hot and cold applications. This makes them valuable in industries that experience extreme environmental conditions.

6. Customizable PU tubes can be manufactured to specific lengths, wall thicknesses, and colors, providing flexibility for different applications and client preferences.

Conclusion

The PU tube with an 8mm diameter is a remarkable product that has found its place across various industries due to its flexibility, durability, and resistance to chemicals. Its wide range of applications, from pneumatic systems to the automotive industry, demonstrates its versatility and reliability. As industries continue to evolve and seek efficient solutions, the demand for high-quality PU tubes is likely to grow, underscoring the importance of this innovative material in modern applications. Investing in PU tubes means investing in performance, longevity, and efficiency—a choice that benefits both manufacturers and end-users alike.

-

Welded Wire Mesh Panel: Durable, Versatile, and AffordableNewsJul.28,2025

-

Top Quality Oxy Acetylene Hoses for Sale Fit for Welding DemandsNewsJul.28,2025

-

The Future of Pneumatic Air Tubes in IndustryNewsJul.28,2025

-

Superior and Reliable LPG Hose Pipe Solutions for Every NeedNewsJul.28,2025

-

Exceptionally Durable and Versatile Premium Braided PVC TubingNewsJul.28,2025

-

Best Adapters for Connecting Garden Hose to PVC Pipe ConnectionsNewsJul.28,2025