Durable and Flexible PU Braided Hose for Versatile Applications and Reliable Performance

Understanding PU Braided Hoses Features, Benefits, and Applications

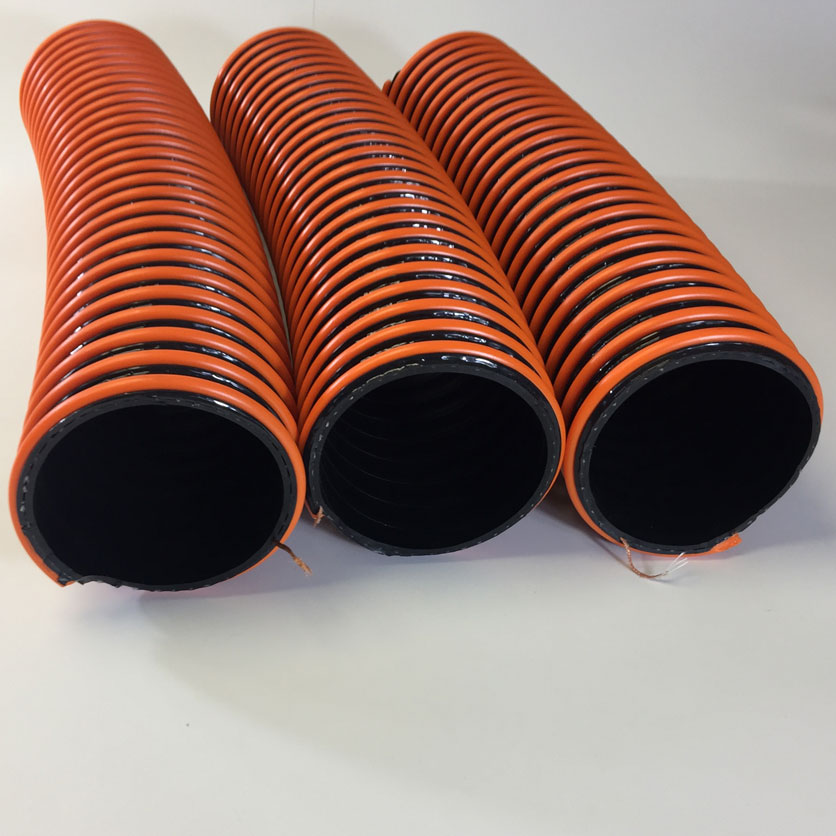

Polyurethane (PU) braided hoses are among the most versatile and durable hose options available in various industrial and commercial applications today. Composed of high-quality polyurethane, these hoses are reinforced with a braided polyester or nylon for added strength and flexibility. In this article, we will dive into the features, benefits, and various applications of PU braided hoses.

Features of PU Braided Hoses

1. Material Composition PU braided hoses are made from a polyurethane compound that offers excellent chemical resistance. This makes them suitable for transporting a variety of fluids, including water, oils, and chemicals.

2. High Pressure Resistance The braided reinforcement adds a significant level of integrity to the hose, allowing it to withstand high pressures. Depending on the design and construction, PU braided hoses can handle pressures up to several thousand psi, making them ideal for industrial applications.

3. Flexibility One of the most notable features of PU braided hoses is their flexibility. Unlike rigid hoses, PU braided hoses can bend and twist, allowing for smooth routing and installation in tight spaces.

4. Abrasion Resistance The polyurethane material is inherently resistant to abrasion, which prolongs the lifespan of the hose. This is especially important in environments where the hose may come in contact with sharp edges or rough surfaces.

5. Lightweight PU braided hoses are significantly lighter than their rubber and metal counterparts, making them easier to handle and install. Their lightweight nature does not compromise their strength, enabling operators to perform tasks with ease without being weighed down.

Benefits of Using PU Braided Hoses

- Durability Due to their robust construction, PU braided hoses exhibit remarkable durability. They resist damage from external factors like environmental exposure, temperature fluctuations, and intense usage.

- Cost-Efficiency The longevity and resistance to wear and tear result in reduced maintenance and replacement costs, contributing to overall cost savings in operational budgets.

pu braided hose

- Versatility PU braided hoses can be used in various settings, from automotive and manufacturing to medical and recreational applications. This versatility makes them a preferred choice for many industries.

- Safety PU braided hoses do not produce toxic emissions and are generally non-toxic. This makes them a safe choice for food and beverage applications, as well as for environments where hygiene is a priority.

Applications of PU Braided Hoses

PU braided hoses are employed in various sectors due to their adaptability and functional advantages. Here are some common applications

1. Automotive Industry These hoses are commonly used in the automotive sector for fuel lines, coolant systems, and pneumatic applications. Their ability to withstand high temperatures and pressures makes them ideal for various automotive functions.

2. Manufacturing In manufacturing plants, PU braided hoses are employed for conveying liquids and gases in production processes. Their durability ensures that they can handle demanding environments.

3. Food and Beverage Due to their non-toxic nature, PU braided hoses are often used for food-grade applications. They meet stringent food safety standards, which is crucial in the food processing industry.

4. Medical Applications In healthcare settings, these hoses are used for medical devices and equipment, where safety and hygiene are paramount. Their flexibility and reliability make them suitable for diverse medical applications.

5. Construction PU braided hoses are also used in construction machinery for hydraulic applications. Their ability to operate in harsh conditions makes them a practical choice for construction sites.

Conclusion

In summary, PU braided hoses are an essential component across multiple industries, admired for their durability, flexibility, and versatility. Their material composition, combined with braided reinforcement, results in a hose capable of withstanding high pressures and various environmental conditions. As industries continue to evolve, the demand for reliable and high-performance hoses like PU braided hoses will only grow, making them a staple in modern-day applications. Whether for industrial processes, automotive systems, or medical devices, PU braided hoses stand out as a reliable choice among hose options in today's market.

-

Top Quality Oxy Acetylene Hoses for Sale Fit for Welding DemandsNewsJul.28,2025

-

The Future of Pneumatic Air Tubes in IndustryNewsJul.28,2025

-

Superior and Reliable LPG Hose Pipe Solutions for Every NeedNewsJul.28,2025

-

Exceptionally Durable and Versatile Premium Braided PVC TubingNewsJul.28,2025

-

Best Adapters for Connecting Garden Hose to PVC Pipe ConnectionsNewsJul.28,2025

-

The Essential Role of LPG Hoses in Safe and Efficient Gas DistributionNewsJul.16,2025