Polyurethane Tubing Suppliers for High-Quality Flexible and Durable Solutions

Understanding Polyurethane Tubing Insights from Manufacturers

Polyurethane tubing is becoming increasingly popular across various industries due to its exceptional flexibility, durability, and resistance to wear and tear. Manufacturers specializing in polyurethane tubing have revolutionized this material into a vital component for different applications, including automotive, medical, and industrial sectors. This article will delve into the characteristics of polyurethane tubing, explore the manufacturing process, and highlight its various applications.

Characteristics of Polyurethane Tubing

One of the most attractive features of polyurethane tubing is its remarkable flexibility. Unlike other materials such as PVC or rubber, polyurethane boasts a higher elasticity which allows for bending and twisting without losing its integrity. This quality is particularly beneficial in applications requiring tight spaces and complex routing pathways.

Another critical characteristic is its impressive resistance to abrasions and harsh environmental conditions. Polyurethane tubing can withstand exposure to chemicals, oils, and UV light, making it an excellent choice for outdoor applications or in environments with fluctuating temperatures. Additionally, it is less likely to crack or become brittle over time compared to other materials, ensuring longevity and reliability.

The clear consistency of polyurethane also allows for visual monitoring of flow, which is essential in applications like fluid transfer in medical devices or food processing. Furthermore, polyurethane can be manufactured in a range of Shore hardness levels, catering to diverse applications that require either soft, flexible tubing or hard, robust solutions.

The Manufacturing Process

The production of polyurethane tubing involves several key steps, starting from the formulation of the polyurethane itself. Manufacturers carefully select raw materials, including polyols and isocyanates, to create a polyurethane mix tailored to specific performance requirements. The mixing process is critical and is performed under controlled conditions to ensure uniformity and quality.

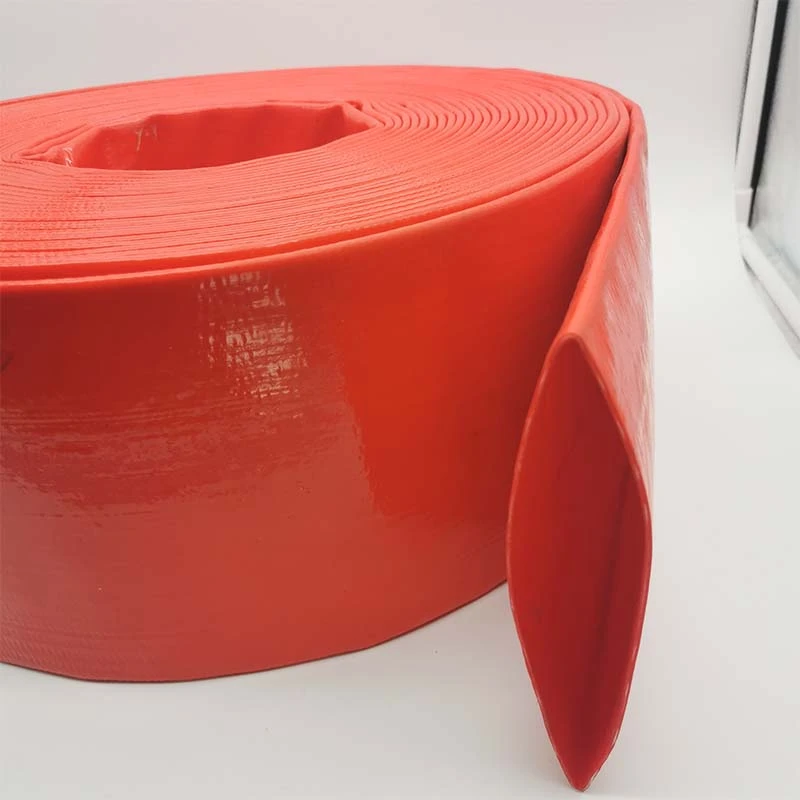

polyurethane tubing manufacturer

Following the formulation, the tubing is produced using various techniques such as extrusion or blow molding. In extrusion, the polyurethane mix is heated and forced through a die to create a continuous length of tubing, which can then be cut to the required sizes. This method allows for efficient mass production with consistent quality.

Quality control is paramount in the manufacturing of polyurethane tubing. Manufacturers conduct rigorous testing to ensure that the final products meet industry standards and customer specifications. This includes assessments of durability, flexibility, and resistance to different environmental factors.

Applications of Polyurethane Tubing

Polyurethane tubing serves a wide range of applications across multiple industries. In the automotive sector, it is commonly used for fuel and coolant lines due to its resistance to chemicals and temperature variations. Its flexibility allows for easy installation in tight engine spaces.

In the medical field, polyurethane tubing is essential for various devices, including catheters and infusion systems. The clarity of the tubing enables clinicians to monitor patient fluids effectively, while its biocompatibility ensures safety during medical procedures.

Additionally, polyurethane tubing is widely used in pneumatic applications. Its lightweight and flexible nature make it ideal for air and fluid movement in manufacturing environments. Industries such as textiles, packaging, and robotics have also adopted polyurethane tubing to enhance operational efficiency.

Conclusion

The expertise found among polyurethane tubing manufacturers is instrumental in driving innovation and meeting the evolving demands of different industries. With its pivotal characteristics—flexibility, durability, and resistance—polyurethane tubing continues to be a preferred choice for many applications. As technology advances and manufacturers refine their processes, the potential for polyurethane tubing will only expand, leading to more specialized and efficient solutions in the future.

-

Welded Wire Mesh Panel: Durable, Versatile, and AffordableNewsJul.28,2025

-

Top Quality Oxy Acetylene Hoses for Sale Fit for Welding DemandsNewsJul.28,2025

-

The Future of Pneumatic Air Tubes in IndustryNewsJul.28,2025

-

Superior and Reliable LPG Hose Pipe Solutions for Every NeedNewsJul.28,2025

-

Exceptionally Durable and Versatile Premium Braided PVC TubingNewsJul.28,2025

-

Best Adapters for Connecting Garden Hose to PVC Pipe ConnectionsNewsJul.28,2025