polyurethane tube price

Understanding Polyurethane Tube Pricing Factors and Trends

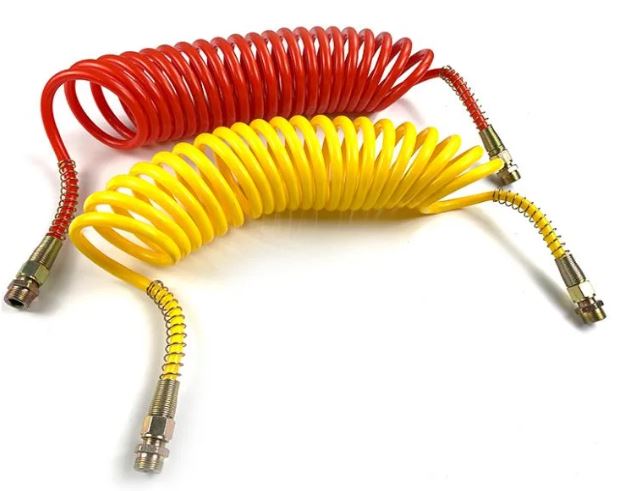

Polyurethane tubes are increasingly popular in various industrial applications due to their versatility, durability, and flexibility. From medical devices to automotive components and even furniture manufacturing, these tubes serve critical functions across multiple sectors. With the growing demand, understanding the pricing dynamics of polyurethane tubes can help businesses make informed purchasing decisions and manage operational costs effectively.

Factors Influencing Polyurethane Tube Prices

1. Raw Material Costs The primary factor affecting the price of polyurethane tubes is the cost of raw materials. Polyurethane is derived from polyols and isocyanates, which are subject to market fluctuations. Prices for these raw materials can vary significantly due to factors such as global supply and demand, production capacity, and geopolitical events. When raw material costs rise, manufacturers typically pass these costs onto consumers.

2. Manufacturing Processes The complexity of the manufacturing process also plays a crucial role in determining the price. Different types of polyurethane tubes require varied production techniques, which can influence labor costs, energy consumption, and the technology used. More advanced manufacturing methods that ensure high quality and precision often come with higher price tags.

3. Quality and Specifications Polyurethane tubes are available in various grades and specifications depending on their intended use. High-performance tubes designed for extreme conditions, such as high-pressure applications or corrosive environments, tend to be more expensive than standard options. Consumers must assess their specific needs when considering price, as investing in higher-quality products may lead to long-term savings through increased durability and reduced maintenance costs.

4. Length and Diameter The dimensions of the tube also significantly impact the price. Custom sizes often become more expensive due to the need for special tooling or molds in the manufacturing process. Conversely, standard sizes produced in bulk can benefit from economies of scale, resulting in lower prices for consumers.

polyurethane tube price

5. Market Trends and Demand Economic cycles and trends in specific industries can drastically affect polyurethane tubing prices. For example, if the automotive or construction sectors see a surge in demand, the increased need for polyurethane components may drive prices upward. Conversely, during economic downturns, prices may stabilize or decrease due to diminished demand.

6. Geographical Variations The location of both suppliers and consumers can influence pricing due to export/import duties, transportation costs, and regional economic conditions. For instance, consumers in remote areas might face higher prices due to increased shipping expenses, while local manufacturers may enjoy lower costs.

Pricing Trends in 2023

As of 2023, the marketplace for polyurethane tubes has witnessed noticeable trends. The ongoing push for sustainable materials has prompted some manufacturers to explore bio-based polyurethanes, which may initially carry a higher price but become increasingly competitive as production expands. Additionally, advancements in recycling technologies have begun to influence pricing, making recycled polyurethane options more accessible.

Another noteworthy trend is the growing demand for customized solutions. Businesses are often seeking specific performance characteristics tailored to their applications. This has led to more manufacturers offering specialized services, sometimes resulting in higher prices but also allowing for better-fit products that can enhance performance and efficiency.

Conclusion

Understanding the price dynamics of polyurethane tubes is essential for businesses looking to optimize their operational efficiency and manage costs. Factors such as raw material prices, manufacturing processes, and market demand play significant roles in determining final costs. As industries continue to evolve and adapt to new technologies and sustainability demands, stakeholders must stay informed about pricing trends to make strategic purchasing decisions. By recognizing the interplay of these elements, businesses can not only navigate the complexities of polyurethane tube pricing but also seize opportunities for innovation and cost savings in their operations.

-

Top Quality Oxy Acetylene Hoses for Sale Fit for Welding DemandsNewsJul.28,2025

-

The Future of Pneumatic Air Tubes in IndustryNewsJul.28,2025

-

Superior and Reliable LPG Hose Pipe Solutions for Every NeedNewsJul.28,2025

-

Exceptionally Durable and Versatile Premium Braided PVC TubingNewsJul.28,2025

-

Best Adapters for Connecting Garden Hose to PVC Pipe ConnectionsNewsJul.28,2025

-

The Essential Role of LPG Hoses in Safe and Efficient Gas DistributionNewsJul.16,2025