Top Manufacturers of Polyurethane Tubes for Various Industrial Applications

The Growing Landscape of Polyurethane Tube Manufacturers

Polyurethane tubes have gained significant traction in various industries due to their impressive properties, which include flexibility, durability, and resistance to abrasion. As technology advances and the demand for high-performance materials in sectors like automotive, construction, and medical continues to increase, the role of polyurethane tube manufacturers becomes increasingly pivotal.

Understanding Polyurethane Tubes

Polyurethane (PU) is a versatile polymer that is formed by the reaction of diisocyanates with polyols. This chemical structure enables the resulting tubes to exhibit a range of thermal and mechanical properties, making them suitable for various applications. Unlike traditional rubber or plastic, PU tubes can withstand extreme temperatures, offer superior resistance to oils and greases, and have excellent tensile strength.

Market Demand and Applications

The demand for polyurethane tubes is particularly robust in industries that require reliable and resilient materials. In the automotive sector, for instance, PU tubes are used for fuel lines, air hoses, and hydraulic systems due to their ability to handle various substances without degradation. The construction industry utilizes these tubes for insulation and weatherproofing applications because of their excellent thermal properties.

In the medical field, polyurethane tubes are used in a variety of applications, including catheters and infusion lines. The biocompatibility of PU makes it an ideal choice for medical devices, as it poses minimal risk of adverse reactions in the body. Furthermore, the lightweight and flexible nature of these tubes facilitates ease of use and manipulation during medical procedures.

The Role of Manufacturers

polyurethane tube manufacturers

The growing demand for polyurethane tubes has led to the emergence of numerous manufacturers specializing in this niche. These companies focus on innovation and quality to meet the diverse requirements of different industries. Manufacturers invest heavily in research and development to enhance the properties of polyurethane materials. They often collaborate with end-users to create tailored solutions that meet specific performance criteria.

Additionally, polyurethane tube manufacturers are increasingly adopting sustainable practices. With the global push toward eco-friendly materials, many companies are exploring the use of bio-based polyols or recycling processes to minimize environmental impact. Sustainable manufacturing practices not only cater to the growing eco-conscious consumer base but also comply with government regulations aimed at reducing industrial waste.

Key Challenges in the Industry

Despite the growth potential, polyurethane tube manufacturers face several challenges. One significant issue is the volatility of raw material prices, particularly the petrochemical sources of polyols and diisocyanates. Fluctuations in oil prices can lead to unpredictability in manufacturing costs, which can ultimately affect pricing strategies in competitive markets.

Another challenge is the necessity for compliance with stringent safety and environmental regulations. As industries shift toward sustainable practices, manufacturers must adapt their processes to meet these new standards, which may require significant investments in new technologies and materials.

Conclusion

The landscape of polyurethane tube manufacturers is evolving, driven by technological advancements and increasing market demand across various sectors. As industries continue to seek high-performance, durable materials, polyurethane tubes are likely to play a critical role in future product innovations. Manufacturers that prioritize quality, sustainability, and adaptability will be well-positioned to capitalize on these emerging opportunities. The ongoing commitment to research and development will be essential in navigating the challenges and ensuring that polyurethane tubes remain a preferred choice in a competitive marketplace.

-

Welded Wire Mesh Panel: Durable, Versatile, and AffordableNewsJul.28,2025

-

Top Quality Oxy Acetylene Hoses for Sale Fit for Welding DemandsNewsJul.28,2025

-

The Future of Pneumatic Air Tubes in IndustryNewsJul.28,2025

-

Superior and Reliable LPG Hose Pipe Solutions for Every NeedNewsJul.28,2025

-

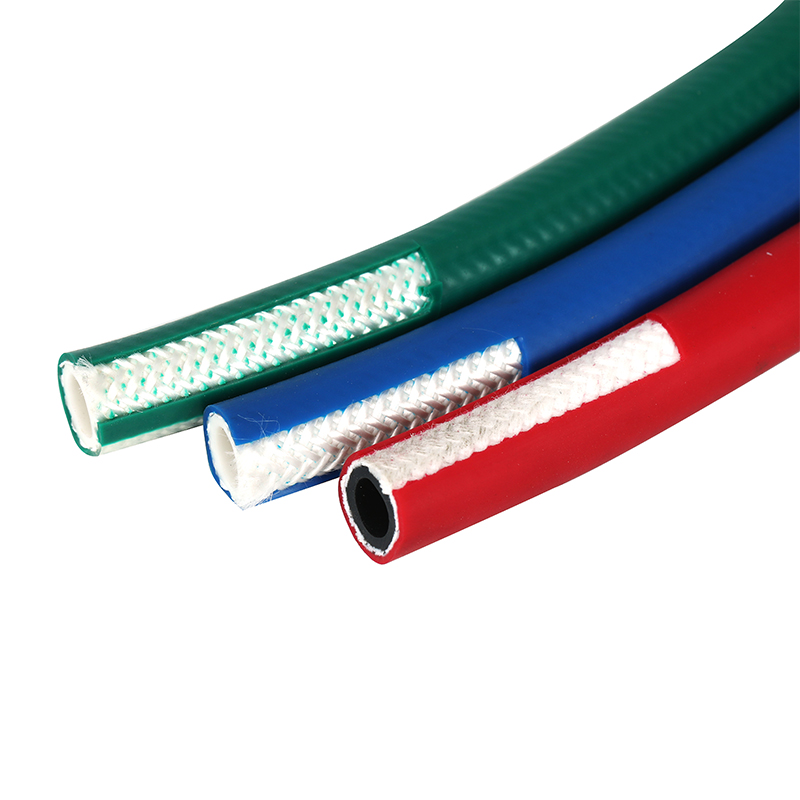

Exceptionally Durable and Versatile Premium Braided PVC TubingNewsJul.28,2025

-

Best Adapters for Connecting Garden Hose to PVC Pipe ConnectionsNewsJul.28,2025