12x8mm Polyurethane Tubing for Flexible Applications and Durable Performance

The Versatility of Polyurethane Tubes A Focus on 12x8mm Dimensions

In the realm of industrial applications, the choice of materials plays a pivotal role in ensuring efficiency, durability, and adaptability. Among the many materials available, polyurethane has emerged as a standout option, especially in the form of tubing. Polyurethane tubes, such as the commonly referenced 12x8mm size, offer a plethora of advantages that make them ideal for various applications across multiple industries.

What is Polyurethane?

Polyurethane is a versatile polymer that can be manufactured in a variety of forms, including rigid, flexible, and elastomeric types. Its unique chemical structure allows for numerous properties, making it highly customizable for specific applications. Polyurethane is known for its excellent abrasion resistance, flexibility, and resilience, which contributes to its popularity in tubing production.

Characteristics of Polyurethane Tubes

When discussing 12x8mm polyurethane tubes, the dimensions refer to the outer diameter (12mm) and inner diameter (8mm) of the tube. This size is particularly favored for applications that require a balance between flexibility and strength. Notably, polyurethane tubing exhibits

1. Flexibility Unlike rigid plastic tubes, polyurethane tubes can bend and twist, making them suitable for dynamic applications where movement is a factor.

2. Chemical Resistance Polyurethane is fairly resistant to a wide range of chemicals, which makes these tubes ideal for transferring liquids, gases, and even corrosive substances.

3. Temperature Resistance They can perform well in a variety of temperatures, maintaining their integrity and functionality in both high and low-temperature environments.

4. Durability These tubes are designed to withstand wear, tear, and impact, which means they are less likely to puncture or tear under stress.

5. Lightweight The lightweight nature of polyurethane tubes makes them easier to install and handle, providing an advantage in various applications.

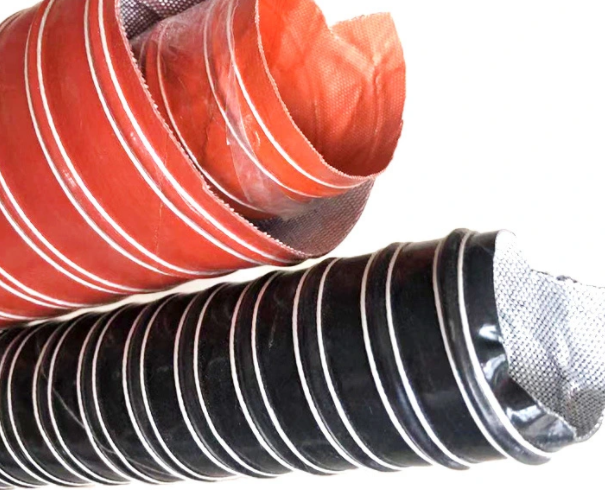

polyurethane tube 12x8mm

Applications of 12x8mm Polyurethane Tubes

Given their advantageous properties, 12x8mm polyurethane tubes find usage in a broad spectrum of applications

- Automotive In vehicles, these tubes are often used in fuel lines, air conditioning systems, and hydraulics due to their flexibility and chemical resistance.

- Pneumatics and Hydraulics In pneumatic systems, polyurethane tubing is used for transmitting air and other gases, while in hydraulics, it is employed for liquid transfer.

- Food and Beverage Food-grade polyurethane tubes are essential for sanitary liquid transfer, such as in the dairy or beverage industries, thanks to their ease of cleaning and resistance to microbial growth.

- Medical Devices The flexibility and sterility of polyurethane make these tubes suitable for various medical applications, including catheters and intravenous lines.

- Construction In building applications, polyurethane tubes are utilized for insulation, weatherproofing, and as part of composite materials, enhancing the durability of structures.

Installation and Maintenance

Installing 12x8mm polyurethane tubing is a straightforward process, usually requiring standard tools. One important consideration is ensuring that the connectors and fittings are compatible with the tube dimensions to prevent leaks. Regular maintenance is essential to maximize the tubes' lifespan—monitoring for wear and replacing any damaged sections promptly.

Conclusion

The 12x8mm polyurethane tube exemplifies the versatility and functionality of polyurethane as a material. Its unique properties make it a preferred choice across a variety of industries, including automotive, pneumatic, medical, and food sectors. As industries continue to evolve and demand higher performance materials, polyurethane tubes will undoubtedly play a crucial role in meeting these needs. Their combination of flexibility, chemical resistance, and durability ensures that they remain an essential component in many applications, promising reliable performance in an increasingly complex industrial landscape. In summary, whether you’re an engineer, a technician, or simply someone interested in material science, understanding the benefits and applications of polyurethane tubing can provide valuable insights into its pivotal role in modern technology.

-

Welded Wire Mesh Panel: Durable, Versatile, and AffordableNewsJul.28,2025

-

Top Quality Oxy Acetylene Hoses for Sale Fit for Welding DemandsNewsJul.28,2025

-

The Future of Pneumatic Air Tubes in IndustryNewsJul.28,2025

-

Superior and Reliable LPG Hose Pipe Solutions for Every NeedNewsJul.28,2025

-

Exceptionally Durable and Versatile Premium Braided PVC TubingNewsJul.28,2025

-

Best Adapters for Connecting Garden Hose to PVC Pipe ConnectionsNewsJul.28,2025