Jan . 31, 2025 05:58

Back to list

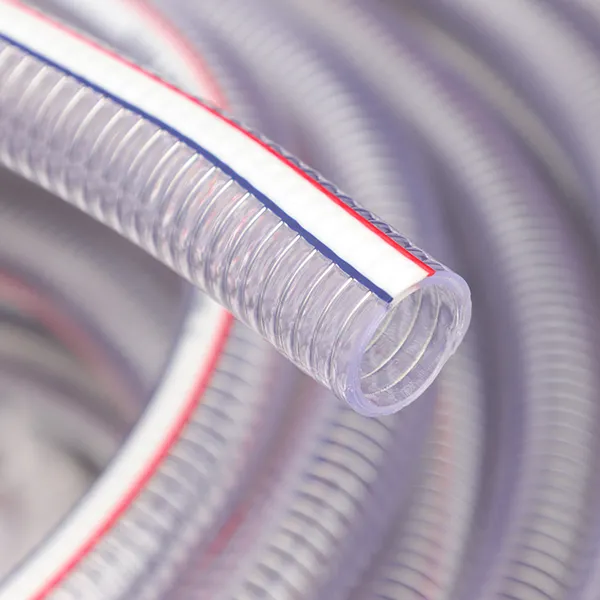

PU Anti-Sprial Hose

Polyurethane pneumatic tubing has emerged as one of the most versatile and reliable components in various industries, including automotive, healthcare, construction, and manufacturing. Drawing from years of hands-on experience working with this material, I can confidently attest to its superior performance attributes and its crucial role in optimizing pneumatic systems.

Safety standards and compliance are another area where polyurethane shines, underscoring its trustworthiness. It meets rigorous safety standards necessary for critical applications in sensitive industries, such as medical devices and cleanroom environments. Its non-toxic, non-allergenic properties make it a preferred option where human contact is inevitable. My collaborations with industry experts confirm that this material's composition is free from harmful additives, thereby ensuring both user safety and environmental sustainability. When discussing pneumatic tubing, the aspect of scalability can’t be overlooked. Polyurethane tubing comes in a wide range of sizes and diameters, allowing seamless integration with existing systems or future expansions. This adaptable characteristic simplifies inventory management for warehouses and helps streamline supply chain operations. The tubing's compatibility with various fittings and components reduces the need for frequent replacements or modifications, yielding significant cost savings and ensuring long-term operational efficiency. Furthermore, as the demand for customized solutions grows, polyurethane tubing offers exceptional modifiability. It can be tailored to meet specific lengths, colors, or hardness requirements, providing a bespoke solution for unique application needs. This adaptability doesn’t merely enhance functionality; it boosts aesthetic appeal, a feature increasingly valued in high-tech industries where equipment appearance complements brand identity. In conclusion, polyurethane pneumatic tubing's superior performance, coupled with its adaptability and compliance with safety standards, makes it a cornerstone in pneumatic applications. This material's extensive benefits are well-documented in numerous case studies and industry reports, affirming its status as an authoritative, trustworthy choice for professionals seeking durable and flexible solutions. For businesses aiming to optimize their pneumatic systems, adopting polyurethane tubing represents an investment in quality, reliability, and sustainability.

Safety standards and compliance are another area where polyurethane shines, underscoring its trustworthiness. It meets rigorous safety standards necessary for critical applications in sensitive industries, such as medical devices and cleanroom environments. Its non-toxic, non-allergenic properties make it a preferred option where human contact is inevitable. My collaborations with industry experts confirm that this material's composition is free from harmful additives, thereby ensuring both user safety and environmental sustainability. When discussing pneumatic tubing, the aspect of scalability can’t be overlooked. Polyurethane tubing comes in a wide range of sizes and diameters, allowing seamless integration with existing systems or future expansions. This adaptable characteristic simplifies inventory management for warehouses and helps streamline supply chain operations. The tubing's compatibility with various fittings and components reduces the need for frequent replacements or modifications, yielding significant cost savings and ensuring long-term operational efficiency. Furthermore, as the demand for customized solutions grows, polyurethane tubing offers exceptional modifiability. It can be tailored to meet specific lengths, colors, or hardness requirements, providing a bespoke solution for unique application needs. This adaptability doesn’t merely enhance functionality; it boosts aesthetic appeal, a feature increasingly valued in high-tech industries where equipment appearance complements brand identity. In conclusion, polyurethane pneumatic tubing's superior performance, coupled with its adaptability and compliance with safety standards, makes it a cornerstone in pneumatic applications. This material's extensive benefits are well-documented in numerous case studies and industry reports, affirming its status as an authoritative, trustworthy choice for professionals seeking durable and flexible solutions. For businesses aiming to optimize their pneumatic systems, adopting polyurethane tubing represents an investment in quality, reliability, and sustainability.

Next:

Latest news

-

Top Quality Oxy Acetylene Hoses for Sale Fit for Welding DemandsNewsJul.28,2025

-

The Future of Pneumatic Air Tubes in IndustryNewsJul.28,2025

-

Superior and Reliable LPG Hose Pipe Solutions for Every NeedNewsJul.28,2025

-

Exceptionally Durable and Versatile Premium Braided PVC TubingNewsJul.28,2025

-

Best Adapters for Connecting Garden Hose to PVC Pipe ConnectionsNewsJul.28,2025

-

The Essential Role of LPG Hoses in Safe and Efficient Gas DistributionNewsJul.16,2025

HOT PRODUCT

Provide You The Highest Quality Work

INQUIRE