Effective Collection Solutions for Polyurethane Dust with Durable Hose Options

Polyurethane Dust Collection Hose An Essential Component for Efficient Dust Management

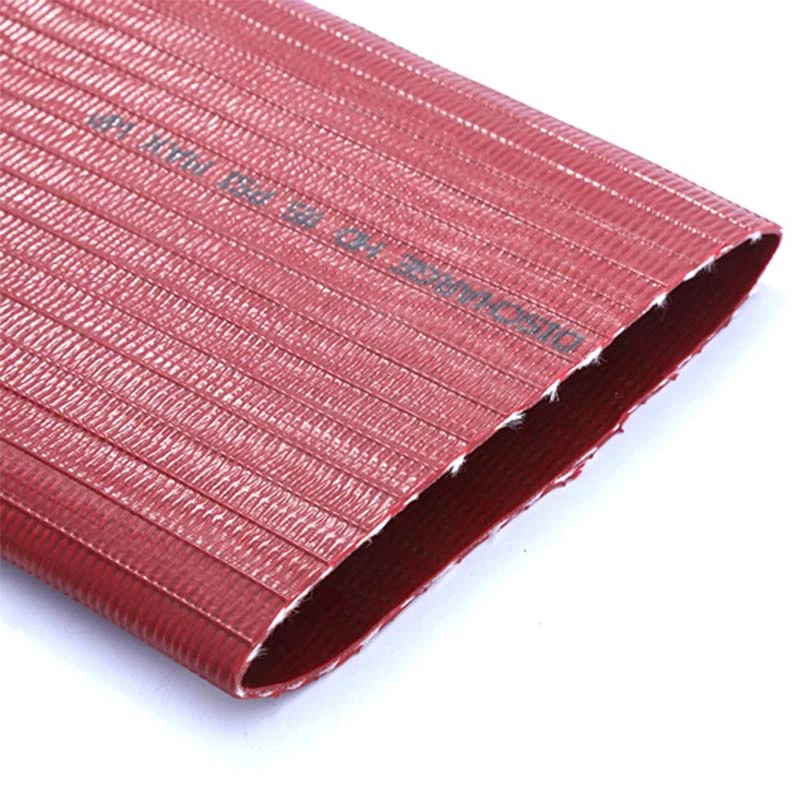

In various industries such as woodworking, metalworking, and manufacturing, dust management is a critical factor in ensuring workplace safety and operational efficiency. A significant element of an effective dust collection system is the type of hose used to transport dust and debris from tools and machines to collection units. Among the range of options available, polyurethane dust collection hoses stand out as a superior choice due to their flexibility, durability, and adaptability.

Properties of Polyurethane Hoses

Polyurethane hoses are popularly recognized for their robust performance in demanding environments. One of the key characteristics of these hoses is their impressive flexibility. Unlike rigid hoses, polyurethane hoses can bend and flex around machines and tools without breaking or pinching. This adaptability allows the hose to reach awkward spaces and connect to various equipment while maintaining a strong airflow, which is vital for effective dust collection.

Moreover, polyurethane is known for its excellent abrasion resistance. In industrial settings, where dust and debris can be abrasive, a hose that wears down quickly can lead to increased maintenance costs and reduced efficiency. Polyurethane hoses are resistant to tearing and scratching, ensuring a longer lifespan compared to hoses made from materials like PVC or rubber. This durability translates into lower replacement costs and less downtime for maintenance.

Benefits of Using Polyurethane Dust Collection Hoses

1. Weight and Portability Polyurethane hoses are typically lighter than their rubber counterparts. This weight advantage makes them easier to handle, maneuver, and install, especially in environments where multiple setups are required.

2. Chemical Resistance Many industries deal with various chemicals and materials that can degrade standard rubber hoses. Polyurethane is highly resistant to many chemicals, making these hoses suitable for diverse applications beyond mere dust collection.

polyurethane dust collection hose

3. Versatility These hoses come in various sizes and configurations, allowing businesses to choose the right specifications that meet their specific dust collection needs. Whether it’s connecting to a high-performance dust collector or a smaller scale setup, polyurethane hoses can be customized to fit.

4. Static Conductivity In environments where static electricity poses a risk, polyurethane hoses can be manufactured to be static dissipative. This feature reduces the likelihood of sparks and explosions, providing a safer working environment for employees.

Applications in Various Industries

Polyurethane dust collection hoses are used in a wide range of applications across multiple sectors. In woodworking, they help to collect sawdust and wood shavings, creating a clean workspace and reducing fire hazards. In metalworking shops, these hoses efficiently remove metal shavings and chips generated during machining processes, ensuring a safe and tidy work environment.

Additionally, in the pharmaceutical and food processing industries, hygiene and cleanliness are paramount. Polyurethane hoses can be easily cleaned and sanitized without compromising their structural integrity, making them ideal for such sensitive applications.

Conclusion

Investing in a polyurethane dust collection hose is an intelligent choice for any industry striving for efficient dust management. With their outstanding flexibility, durability, and resistance to wear and tear, polyurethane hoses not only enhance performance but also promote health and safety in the workplace. As industries continue to evolve and prioritize effective dust management solutions, polyurethane dust collection hoses will remain a go-to option for achieving optimal results. By ensuring that dust and debris are effectively removed from work areas, these hoses play a critical role in maintaining a productive and safe working environment for all employees.

-

Top Quality Oxy Acetylene Hoses for Sale Fit for Welding DemandsNewsJul.28,2025

-

The Future of Pneumatic Air Tubes in IndustryNewsJul.28,2025

-

Superior and Reliable LPG Hose Pipe Solutions for Every NeedNewsJul.28,2025

-

Exceptionally Durable and Versatile Premium Braided PVC TubingNewsJul.28,2025

-

Best Adapters for Connecting Garden Hose to PVC Pipe ConnectionsNewsJul.28,2025

-

The Essential Role of LPG Hoses in Safe and Efficient Gas DistributionNewsJul.16,2025