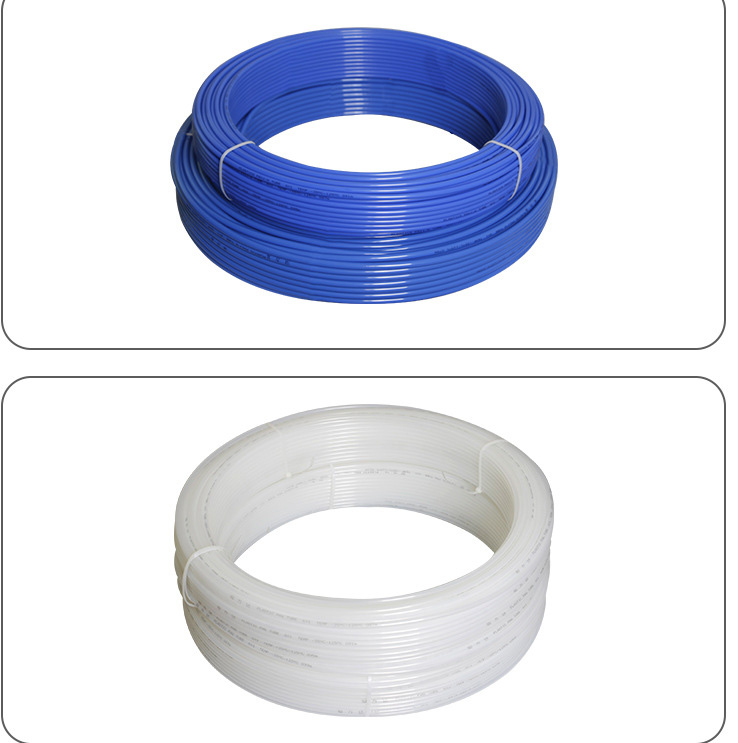

polyurethane ducting hose

Understanding Polyurethane Ducting Hose An Essential Component in Modern Industries

Polyurethane ducting hoses are gaining prominence as crucial components across various industries due to their versatility, durability, and efficiency. These hoses are specifically designed to transport air, dust, fumes, or other materials with ease, making them vital for applications in construction, manufacturing, and HVAC systems. In this article, we delve into the characteristics, benefits, and applications of polyurethane ducting hoses to help you understand why they are indispensable in modern industrial operations.

What is Polyurethane?

Polyurethane is a versatile polymer that is highly flexible, resilient, and abrasion-resistant. This material can be produced in various forms, including foams, elastomers, and coatings. In the context of ducting hoses, polyurethane offers numerous advantages over traditional materials such as rubber and PVC. Its lightweight nature enhances ease of handling, while its resistance to wear and tear contributes to a longer service life.

Key Characteristics of Polyurethane Ducting Hoses

1. Flexibility and Elasticity Polyurethane ducting hoses are known for their excellent flexibility, allowing them to bend and twist without producing kinks or blockages. This feature makes them adaptable to various installation needs and environments.

2. Durability One of the standout characteristics of polyurethane is its remarkable durability. These hoses can withstand significant wear and tear, enabling them to function effectively in harsh conditions where other hoses might fail.

4. Temperature Tolerance The material can operate efficiently in a wide range of temperatures, typically from -40°F to +200°F, depending on the specific formulation. This versatility makes polyurethane ducting hoses suitable for both cold and hot applications.

5. Lightweight Compared to traditional ducting materials, polyurethane hoses are considerably lighter yet maintain strength and resilience. This lightweight quality aids in installation and reduces the overall load on support structures.

polyurethane ducting hose

Applications of Polyurethane Ducting Hoses

Polyurethane ducting hoses find their applications in numerous sectors, reflecting their versatility

1. Construction In construction sites, these hoses are commonly used for dust extraction and ventilation. Their robustness allows them to handle construction debris without compromising performance.

2. Manufacturing In manufacturing environments, they are utilized for transporting air and dust particles, contributing to a cleaner and safer workplace. Additionally, their resistance to chemicals makes them ideal for industries dealing with various substances.

3. HVAC Systems Polyurethane ducting hoses are frequently employed in heating, ventilation, and air conditioning (HVAC) systems. Their flexibility and durability contribute to efficient air distribution, enhancing overall system performance.

4. Automotive Industry These hoses also play a role in the automotive sector for the delivery of air and fumes, particularly in exhaust systems and ventilation setups.

5. Agriculture In agricultural settings, polyurethane hoses can be used for transferring air in ventilated storage facilities, ensuring optimal conditions for stored products.

Conclusion

In summary, polyurethane ducting hoses represent a significant advancement in industrial materials, offering features that outperform traditional alternatives. Their flexibility, durability, chemical resistance, and lightweight nature make them ideal for a range of applications across various industries. As industries continue to evolve and demand more efficient and reliable solutions, polyurethane ducting hoses are set to play an increasingly important role in enhancing operational efficiency, safety, and productivity. Whether you're in construction, manufacturing, HVAC, automotive, or agriculture, understanding the benefits of polyurethane ducting hoses can help you make informed decisions in your operations. Investing in high-quality ducting solutions is essential for meeting the challenges of modern industrial environments and ensuring long-term success.

-

Top Quality Oxy Acetylene Hoses for Sale Fit for Welding DemandsNewsJul.28,2025

-

The Future of Pneumatic Air Tubes in IndustryNewsJul.28,2025

-

Superior and Reliable LPG Hose Pipe Solutions for Every NeedNewsJul.28,2025

-

Exceptionally Durable and Versatile Premium Braided PVC TubingNewsJul.28,2025

-

Best Adapters for Connecting Garden Hose to PVC Pipe ConnectionsNewsJul.28,2025

-

The Essential Role of LPG Hoses in Safe and Efficient Gas DistributionNewsJul.16,2025