Durable Polyurethane Braided Hoses for Enhanced Flexibility and Strength in Various Applications

Understanding Polyurethane Braided Hoses A Comprehensive Overview

Polyurethane braided hoses have surged in popularity across various industries due to their unique advantages and versatility. This article delves into the properties, applications, and benefits of polyurethane braided hoses, highlighting why they are a preferred choice for many applications.

What are Polyurethane Braided Hoses?

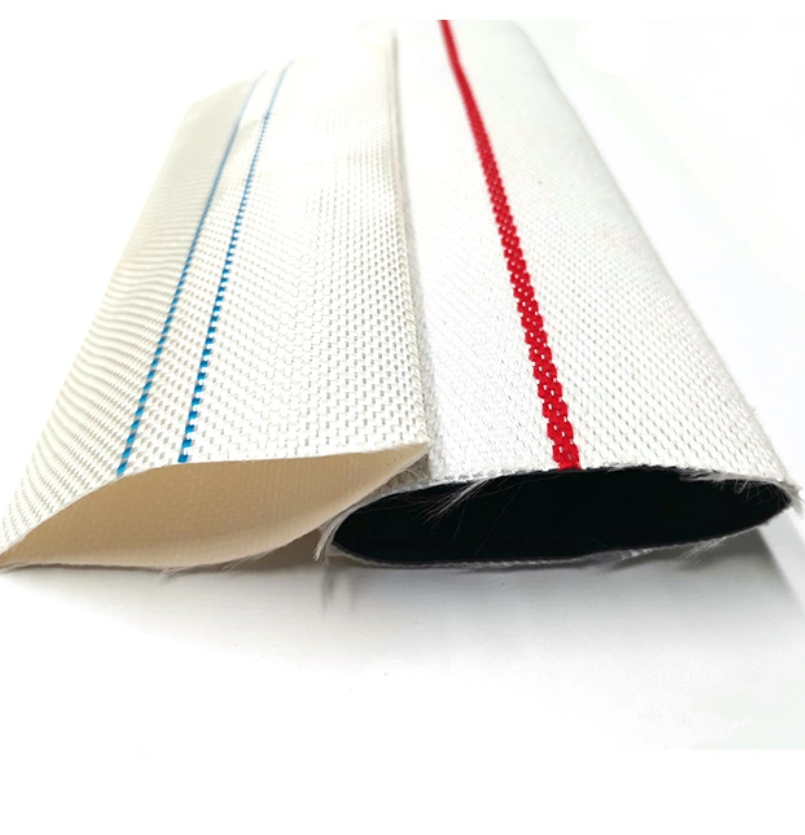

Polyurethane braided hoses are comprised of a flexible outer layer made from polyurethane, reinforced with a braided mesh, typically formed from polyester or nylon fibers. This construction bestows the hoses with exceptional strength and durability while maintaining flexibility, making them ideal for a wide range of applications. The use of polyurethane as the primary material adds characteristics such as abrasion resistance, oil compatibility, and low-temperature flexibility.

Key Properties of Polyurethane Braided Hoses

1. Durability Polyurethane hoses are highly resistant to wear and tear. The braided design significantly enhances tensile strength, making them less prone to bursting under high pressure and extending their lifespan compared to non-braided alternatives.

2. Chemical Resistance Polyurethane is inherently resistant to various chemicals, making these hoses suitable for transporting liquids and gases that might otherwise degrade other types of hoses. This property is particularly beneficial in the automotive and manufacturing industries.

3. Flexibility The flexibility of polyurethane allows for easy maneuverability in tight spaces, which is essential in many industrial scenarios. This flexibility does not compromise the hose's structural integrity, allowing it to maintain its shape under different operating conditions.

4. Lightweight Compared to rubber or metal hoses, polyurethane braided hoses are significantly lighter. This characteristic makes them easier to handle and install, reducing physical strain for workers and lowering transportation costs.

5. Temperature Tolerance Polyurethane can maintain its performance across a broad range of temperatures, from sub-zero to elevated temperatures, allowing its use in varied environments.

Applications of Polyurethane Braided Hoses

The versatility of polyurethane braided hoses enables their use in numerous applications across various sectors

polyurethane braided hose

1. Automotive In the automotive industry, these hoses are commonly used for fuel lines, coolant systems, and air intake systems due to their durability and chemical resistance.

2. Industrial Manufacturing plants utilize polyurethane braided hoses in pneumatic systems and as transfer lines for various materials, thanks to their robustness and ability to handle different pressures.

3. Medical In healthcare, these hoses play a vital role in medical devices and equipment, where their non-reactive properties ensure patient safety.

4. Construction Construction sites rely on polyurethane hoses for equipment and machinery, where flexibility and durability are crucial for operational efficiency.

5. Food and Beverage Special grades of polyurethane braided hoses are available that meet food safety standards, enabling their use in food processing and delivery systems.

Advantages of Using Polyurethane Braided Hoses

The benefits of choosing polyurethane braided hoses extend beyond their physical properties. Notably

- Cost-Effectiveness Given their durability and long lifespan, polyurethane hoses can lead to reduced replacement costs over time, providing significant value to businesses.

- Reduced Maintenance The robustness and versatility of these hoses result in lower maintenance requirements and fewer operational downtimes.

- Customizability Manufacturers can produce polyurethane braided hoses in various sizes, lengths, and colors, allowing customization to meet specific industry needs.

Conclusion

Polyurethane braided hoses represent a merger of performance and flexibility, making them a popular choice across countless industries. Their unique properties ensure that they perform well under pressure, withstand harsh chemical environments, and maintain functionality across varied temperatures. As industries continue to evolve and seek durable solutions, the relevance of polyurethane braided hoses remains strong, making them an integral component in the landscape of modern industrial applications. Whether in automotive, medical, or manufacturing settings, these hoses provide a reliable, efficient, and cost-effective solution to the demands of contemporary operations.

-

Top Quality Oxy Acetylene Hoses for Sale Fit for Welding DemandsNewsJul.28,2025

-

The Future of Pneumatic Air Tubes in IndustryNewsJul.28,2025

-

Superior and Reliable LPG Hose Pipe Solutions for Every NeedNewsJul.28,2025

-

Exceptionally Durable and Versatile Premium Braided PVC TubingNewsJul.28,2025

-

Best Adapters for Connecting Garden Hose to PVC Pipe ConnectionsNewsJul.28,2025

-

The Essential Role of LPG Hoses in Safe and Efficient Gas DistributionNewsJul.16,2025