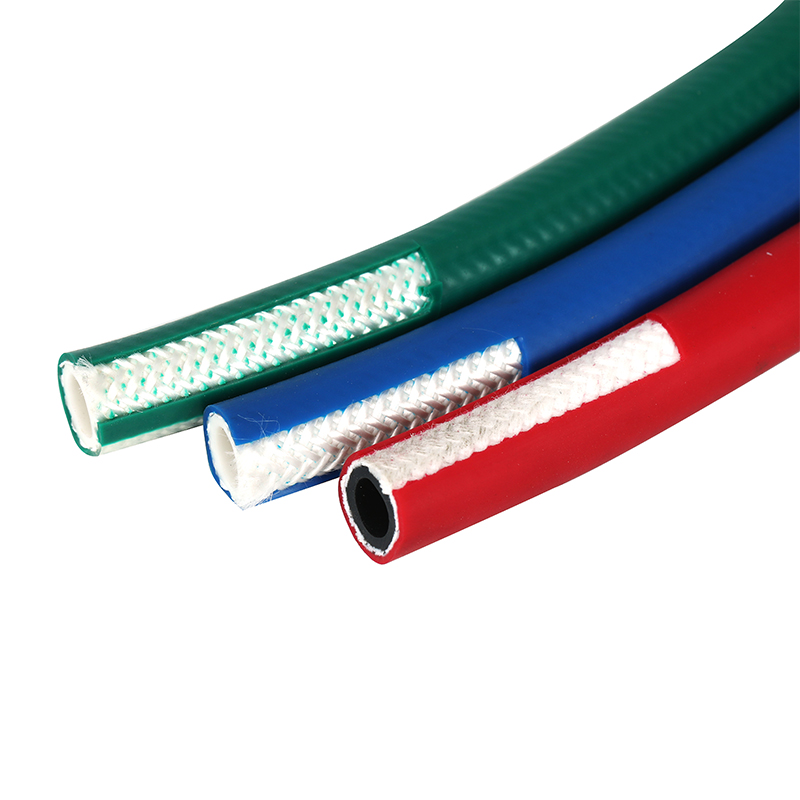

Flexible Polyurethane Braided Hose for Enhanced Durability and Performance in Various Applications

Exploring the Benefits and Applications of Polyurethane Braided Hose

When it comes to industrial applications, the choice of hose material is critical. Among various options, polyurethane braided hose has emerged as a preferred choice for many industries due to its remarkable properties and versatility. This article delves into the benefits, applications, and features of polyurethane braided hoses, highlighting why they are an excellent option for fluid transfer and other uses.

Polyurethane, often abbreviated as PU, is a polymer that exhibits a unique combination of properties, including flexibility, durability, and resistance to abrasion. When braided, this material gains additional strength and pressure resistance, making polyurethane braided hoses particularly effective in high-stress environments. The braiding offers enhanced tensile strength without compromising flexibility, which is essential for handling bends and tight spaces in various setups.

One of the most commendable features of polyurethane braided hose is its exceptional durability. These hoses exhibit remarkable resistance to wear, tear, and damage from environmental factors. Unlike rubber hoses, polyurethane braided hoses are less likely to dry out or crack under ultraviolet (UV) light exposure. This characteristic makes them suitable for outdoor applications where hoses are often exposed to sunlight and harsh weather conditions.

Moreover, polyurethane braided hoses stand out due to their chemical resistance. They can withstand exposure to a variety of chemicals, including oils, fuels, and solvents, making them applicable in numerous industrial sectors such as automotive, aerospace, and manufacturing. Their ability to maintain structural integrity despite exposure to corrosive substances enhances their reliability and longevity.

polyurethane braided hose

Another significant advantage of polyurethane braided hoses is their lightweight nature. Compared to traditional metal or rubber hoses, polyurethane alternatives are significantly lighter, which simplifies handling and installation. This reduced weight can lead to lower shipping costs and ease of use in mobile applications or automated production settings where hoses are constantly repositioned.

In addition to their physical and chemical properties, polyurethane braided hoses are highly flexible, allowing for smooth and efficient fluid transportation. This flexibility minimizes kinking and enhances flow rates, ensuring that operations run smoothly without interruptions. Industries such as food and beverage or pharmaceuticals benefit particularly from this feature, as consistent flow rates are crucial for maintaining quality standards.

Polyurethane braided hoses are also transparent, allowing for easy monitoring of fluid flow and potential blockages. This visual accessibility is advantageous in applications where supervision is key, such as in laboratories or food processing facilities. Users can easily identify any abnormalities in flow, allowing for swift action to prevent disruptions to the process.

As for applications, polyurethane braided hoses are used across a broad spectrum of industries. They are commonly employed in pneumatic systems, where air or other gases require safe transfer. Their versatility also extends to hydraulic applications, water delivery, and even as fuel lines in automotive settings. Additionally, these hoses serve vital roles in medical equipment, ensuring safe and effective fluid transfer while meeting stringent regulatory standards.

In conclusion, polyurethane braided hoses present a myriad of advantages that make them a go-to choice for various industrial applications. Their combination of durability, chemical resistance, lightweight structure, flexibility, and visibility contribute to their growing popularity among manufacturers and engineers alike. When selecting hoses for specific applications, understanding these benefits can guide informed decisions, leading to improved operational efficiency and safety. As industries continue to evolve, the role of high-performance materials like polyurethane will undoubtedly remain essential in facilitating progress and innovation.

-

Welded Wire Mesh Panel: Durable, Versatile, and AffordableNewsJul.28,2025

-

Top Quality Oxy Acetylene Hoses for Sale Fit for Welding DemandsNewsJul.28,2025

-

The Future of Pneumatic Air Tubes in IndustryNewsJul.28,2025

-

Superior and Reliable LPG Hose Pipe Solutions for Every NeedNewsJul.28,2025

-

Exceptionally Durable and Versatile Premium Braided PVC TubingNewsJul.28,2025

-

Best Adapters for Connecting Garden Hose to PVC Pipe ConnectionsNewsJul.28,2025