Choosing the Right Material for Pneumatic Tubing Applications and Performance

Exploring Pneumatic Tubing Materials An Essential Component for Industrial Applications

Pneumatic systems play a vital role in various industries, offering effective solutions for automation and process control. One of the key components of these systems is pneumatic tubing, which serves as the conduit for compressed air to power actuators, cylinders, and other equipment. The selection of appropriate tubing materials is crucial, as it directly affects system performance, efficiency, and longevity.

Pneumatic tubing is primarily made from three types of materials polyurethane (PU), nylon (PA), and polyethylene (PE). Each of these materials possesses unique properties that make them suitable for specific applications.

Polyurethane (PU) is a popular choice for pneumatic tubing due to its excellent flexibility, durability, and abrasion resistance. PU tubing can withstand repeated bending, making it ideal for installations where the tubing may be subjected to movement or vibration. It also has a high tolerance for extreme temperatures, allowing it to perform effectively in various environmental conditions. Additionally, PU is resistant to many chemicals, which is beneficial in industries where exposure to harsh substances is a concern.

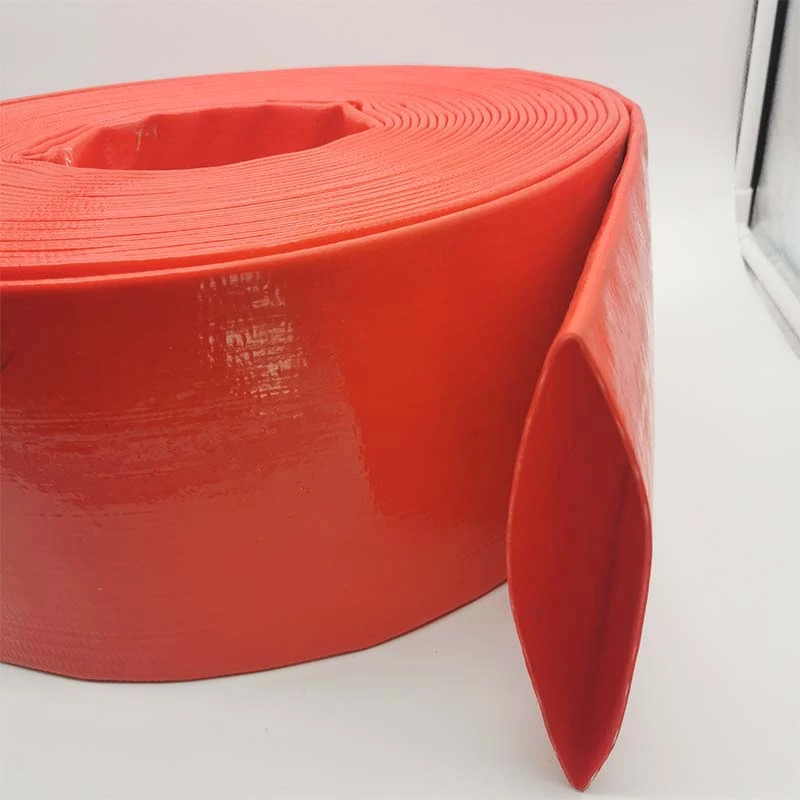

pneumatic tubing material

Nylon (PA) tubing is another commonly used material known for its strength and rigidity. Nylon offers superior tensile strength and is less prone to deformation under pressure, making it suitable for high-pressure applications. It also has good resistance to moisture and many chemicals; however, it may become brittle over time when exposed to UV light. For applications requiring a sturdier solution, nylon tubing is often preferred, especially in environments where the tubing may encounter sharp edges or significant wear and tear.

Polyethylene (PE) is a lightweight and economical option for pneumatic tubing. While it may not have the same level of flexibility or chemical resistance as PU or nylon, it excels in applications involving low pressures. PE tubing is often used in food and beverage industries due to its non-toxic properties. It is also straightforward to install, making it a favorite choice in temporary or less demanding pneumatic systems.

When selecting pneumatic tubing material, several factors should be considered, including pressure rating, temperature range, flexibility, chemical compatibility, and the operational environment. Understanding these specifications helps in choosing the right tubing to ensure optimal system performance.

In conclusion, the choice of pneumatic tubing material significantly impacts the efficiency and reliability of pneumatic systems. With options like polyurethane, nylon, and polyethylene available, it is crucial for engineers and technicians to assess their specific application needs before making a decision. Proper material selection can lead to enhanced performance, reduced maintenance costs, and increased lifespan of pneumatic systems, ultimately contributing to improved productivity in industrial operations.

-

Welded Wire Mesh Panel: Durable, Versatile, and AffordableNewsJul.28,2025

-

Top Quality Oxy Acetylene Hoses for Sale Fit for Welding DemandsNewsJul.28,2025

-

The Future of Pneumatic Air Tubes in IndustryNewsJul.28,2025

-

Superior and Reliable LPG Hose Pipe Solutions for Every NeedNewsJul.28,2025

-

Exceptionally Durable and Versatile Premium Braided PVC TubingNewsJul.28,2025

-

Best Adapters for Connecting Garden Hose to PVC Pipe ConnectionsNewsJul.28,2025