Cost Analysis of Pneumatic Tube Systems and Their Components

Understanding Pneumatic Tube Pricing Factors and Considerations

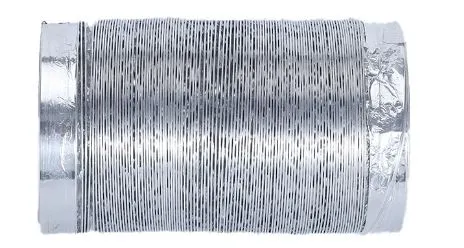

Pneumatic tube systems are an essential component in many industries, providing a fast and efficient method for transporting documents, small items, and medications within facilities such as hospitals, banks, and warehouses. Their increasing popularity has inevitably led to questions regarding the cost associated with purchasing, installing, and maintaining these systems. Understanding pneumatic tube prices entails a comprehensive look at various factors that influence these costs.

Initial Costs

The initial cost of pneumatic tube systems can vary widely based on the complexity of the installation and the specific requirements of the facility. Smaller systems might begin around $10,000, while larger, more complex setups can exceed $100,000. The pricing depends on the number of stations, the length of the tubing network, and whether specialized equipment is needed. Facilities with specific layout challenges or high-volume needs may require customized solutions that can drive up costs significantly.

Components of Pricing

When considering the price of a pneumatic tube system, it’s important to assess the various components involved in its setup

. Key elements include1. Tubes and Stations The main components comprise the tubes themselves, along with the sending and receiving stations. The material and diameter of the tubes, as well as the design of the stations, can affect pricing. 2. Air Compressors A strong and reliable air compressor is necessary to propel the capsules through the tubes. The cost of compressors varies depending on their size and efficiency.

3. Installation Professional installation is often needed, particularly for larger or more complex systems. Installation costs can typically add 20-30% to the overall project expense.

4. Control Systems Sophisticated systems may require advanced controls and software, which can add substantial costs, especially if integration with existing facility management systems is necessary.

pneumatic tube price

Maintenance and Operating Costs

Beyond the initial setup, ongoing maintenance is a critical aspect of pneumatic tube systems. Regular maintenance is essential to ensure the system functions efficiently and prolongs its lifespan. Maintenance contracts can vary in price but might cost several thousand dollars annually depending on the service level agreed upon.

Operating costs, such as electricity usage for running the compressors and periodic replacement of tubes or capsules, should also be factored into the overall budget. Understanding the energy consumption of the system is crucial, especially for high-traffic environments.

Price Variability and Market Trends

Market trends can significantly influence pneumatic tube prices. For instance, inflation in material costs, availability of supplies, and advances in technology could sway pricing structures. The introduction of energy-efficient compressors and smarter control systems also reflects broader trends in construction and manufacturing, likely impacting costs in the coming years.

Customization and Versatility

Customization can greatly affect pricing. Facilities with unique needs may require specialized configurations, which can escalate costs. However, this customization can vastly improve operational efficiency, justifying the higher initial investment. Versatile systems can adapt to changing needs, providing long-term savings and flexibility that can outweigh upfront expenses.

Conclusion

Pneumatic tube systems represent a significant investment, with prices ranging based on various factors, including system complexity, material choices, and installation requirements. While the initial expenditure may appear steep, understanding ongoing costs and the potential for operational efficiencies can help justify the investment. As industries continue to seek faster and more reliable methods of internal transportation, pneumatic tube systems are likely to remain a valuable asset in streamlining operations. Understanding the pricing landscape allows businesses to make informed decisions, balancing cost with the efficiency and effectiveness that pneumatic tube systems can provide. Ultimately, evaluating both immediate costs and long-term benefits is essential for any organization considering this technology.

-

Welded Wire Mesh Panel: Durable, Versatile, and AffordableNewsJul.28,2025

-

Top Quality Oxy Acetylene Hoses for Sale Fit for Welding DemandsNewsJul.28,2025

-

The Future of Pneumatic Air Tubes in IndustryNewsJul.28,2025

-

Superior and Reliable LPG Hose Pipe Solutions for Every NeedNewsJul.28,2025

-

Exceptionally Durable and Versatile Premium Braided PVC TubingNewsJul.28,2025

-

Best Adapters for Connecting Garden Hose to PVC Pipe ConnectionsNewsJul.28,2025