oxy acetylene hose sizes

Understanding Oxy-Acetylene Hose Sizes

Oxy-acetylene welding is a versatile and widely used process in various industrial applications, thanks to its ability to produce high-temperature flames suitable for cutting, welding, and brazing metals. The equipment used in this process is crucial for safety and effectiveness, and one key component is the oxy-acetylene hose. Understanding the sizes of these hoses is essential for selecting the right equipment, ensuring safety, and achieving optimal performance.

Types of Hoses

Oxy-acetylene hoses are typically color-coded to distinguish between the two gases the oxygen hose is green, while the acetylene hose is red. This color-coding is not just for convenience; it plays a vital role in safety by preventing mix-ups that could lead to dangerous situations.

The hoses themselves are designed to withstand high pressures and temperatures. They are usually made from materials such as rubber or thermoplastic, featuring a reinforced construction to prevent leaks and bursts. This construction is essential, given the highly flammable nature of acetylene and the high pressures at which oxygen is stored.

Hose Sizes

Hoses come in various sizes, typically measured in diameter. The most common sizes for oxy-acetylene hoses are 1/4 inch, 3/8 inch, and 1/2 inch. The size of the hose directly affects the flow rate of the gases, which in turn influences the flame characteristics. Thicker hoses can allow for a higher flow rate, enabling a larger flame suitable for heavier materials, while smaller hoses might be more appropriate for lighter tasks or precision work.

1. 1/4 Inch Hose This size is often used for lighter-duty applications. It is suitable for small welding jobs, repairs, and tasks that require less heat. The lower flow rate makes it easier to control the flame, making it ideal for delicate work.

oxy acetylene hose sizes

2. 3/8 Inch Hose The 3/8 inch hose strikes a balance between performance and control. It is versatile enough for general welding tasks and is commonly used in workshops. This size can support a greater flow rate, allowing for a more robust flame while still being manageable for various applications.

3. 1/2 Inch Hose The 1/2 inch hose is designed for heavy-duty welding and cutting tasks. This size provides a significant flow of gases, suitable for large projects or thick metalwork. Its robust construction is essential for high-pressure environments and ensures maximum safety.

Choosing the Right Size

Choosing the right hose size is critical for both safety and performance. A hose that is too small can restrict gas flow, leading to an inconsistent flame and potential safety hazards. Conversely, a hose that is too large may provide unnecessary excess flow, which can be dangerous with flammable gases.

When selecting a hose, consider your specific welding needs, the thickness of the materials you are working with, and the equipment you will be using. Additionally, ensure that the hoses are compatible with the connectors and regulators of your oxy-acetylene setup.

Conclusion

Understanding oxy-acetylene hose sizes is essential for anyone involved in welding or cutting operations. By selecting the correct hose size, you can improve the safety and efficiency of your work. Regular maintenance and inspection of hoses are also important to prevent leaks and ensure that your welding setup functions optimally. Always prioritize safety by using hoses that meet industry standards and are suitable for your specific application. By doing so, you will not only enhance your welding experience but also ensure the safety of everyone in the vicinity.

-

Top Quality Oxy Acetylene Hoses for Sale Fit for Welding DemandsNewsJul.28,2025

-

The Future of Pneumatic Air Tubes in IndustryNewsJul.28,2025

-

Superior and Reliable LPG Hose Pipe Solutions for Every NeedNewsJul.28,2025

-

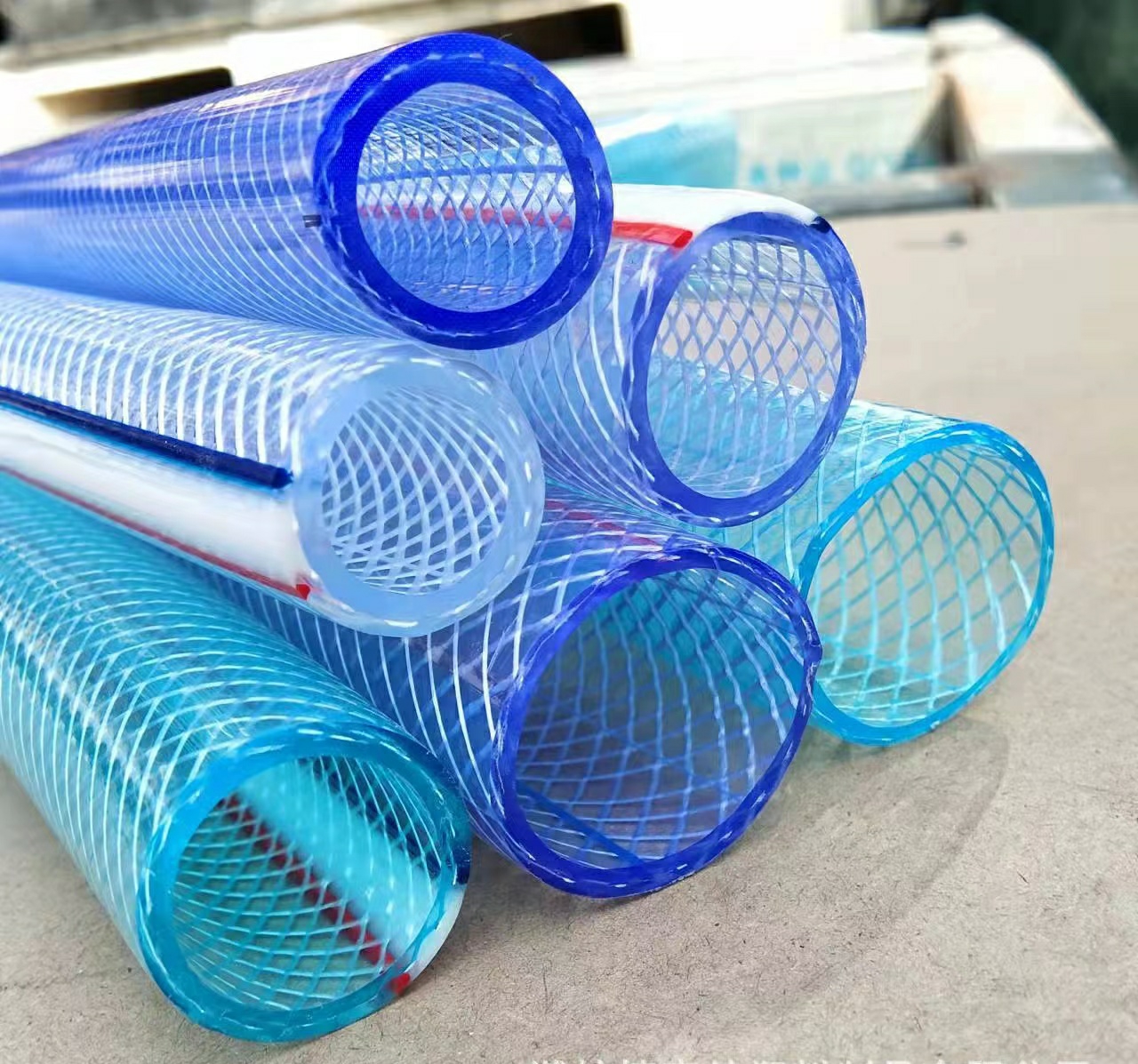

Exceptionally Durable and Versatile Premium Braided PVC TubingNewsJul.28,2025

-

Best Adapters for Connecting Garden Hose to PVC Pipe ConnectionsNewsJul.28,2025

-

The Essential Role of LPG Hoses in Safe and Efficient Gas DistributionNewsJul.16,2025