lpg hose pipe

The Importance of LPG Hose Pipes in Industrial and Domestic Applications

LPG (Liquefied Petroleum Gas) is a versatile fuel used widely in both industrial and domestic settings. To transport LPG safely and efficiently from its source to the end-use point, the quality and reliability of the hose pipes employed are crucial. LPG hose pipes are specially designed to handle the unique characteristics of liquefied petroleum gas, ensuring safe and effective transfer.

Understanding LPG Hose Pipe Features

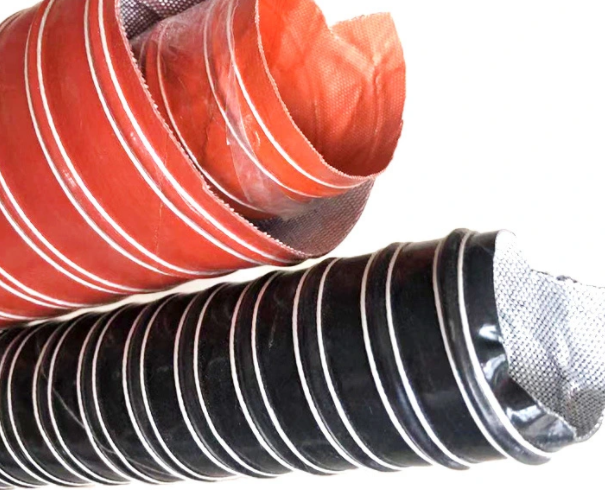

LPG hose pipes are constructed with durable materials that can withstand high pressure and varying temperature conditions associated with LPG. The inner lining of these hoses is often made from synthetic rubber or thermoplastic elastomers, which are resistant to the corrosive effects of propane and butane, the primary components of LPG. This construction not only extends the lifespan of the hose but also minimizes the risk of leaks, which can lead to dangerous situations.

The outer layer of the hose is designed to withstand environmental stresses, including UV radiation, weather conditions, and mechanical abrasion. Some hoses even feature braided or spiral reinforcement to enhance their robustness and flexibility. These features collectively ensure that LPG hose pipes maintain their integrity during operation, preventing failures that could have catastrophic consequences.

Safety Standards and Regulations

Given the potential hazards associated with LPG, the manufacturing and use of hose pipes are subject to stringent safety standards. Organizations such as the American Society for Testing and Materials (ASTM) and the National Fire Protection Association (NFPA) establish guidelines that ensure hoses are built for rigorous use. These guidelines dictate factors such as pressure ratings, temperature limits, and compatibility with various LPG compositions.

lpg hose pipe

Regular maintenance and inspection of LPG hose pipes are equally important. Routine checks can reveal wear and tear, which, if left unaddressed, could lead to leaks. Industry professionals recommend that users replace hoses based on their lifespan or observed condition rather than solely relying on age. Identifying and mitigating risks associated with LPG hose pipes is essential in prolonging the equipment’s life and ensuring safety.

Applications of LPG Hose Pipes

LPG hose pipes have a wide range of applications across various industries. In residential settings, they are commonly used for connecting gas appliances, such as stoves, heaters, and barbecues. Their flexibility and ease of installation make them an ideal choice for domestic use.

In industrial contexts, LPG hose pipes are essential for power generation, cooking processes, and heating systems in commercial kitchens. Their reliability and safety features make them favorable for industries that rely on portable gas solutions. Furthermore, the ability to custom-engineer hoses for specific requirements means that various sectors can benefit from tailored solutions that enhance operational efficiency.

Conclusion

In conclusion, LPG hose pipes play an invaluable role in the safe transportation and application of liquefied petroleum gas across multiple settings. Their design, adherence to safety standards, and versatile applications underscore the importance of investing in high-quality hose pipes. Whether for domestic convenience or industrial efficiency, the right LPG hose pipe ensures that operations run smoothly and safely, highlighting its significance in today’s energy-dependent society. As we continue to harness LPG for various applications, the importance of reliable hose pipes cannot be overstated.

-

Top Quality Oxy Acetylene Hoses for Sale Fit for Welding DemandsNewsJul.28,2025

-

The Future of Pneumatic Air Tubes in IndustryNewsJul.28,2025

-

Superior and Reliable LPG Hose Pipe Solutions for Every NeedNewsJul.28,2025

-

Exceptionally Durable and Versatile Premium Braided PVC TubingNewsJul.28,2025

-

Best Adapters for Connecting Garden Hose to PVC Pipe ConnectionsNewsJul.28,2025

-

The Essential Role of LPG Hoses in Safe and Efficient Gas DistributionNewsJul.16,2025