LPG Hose Safety Standards and Best Practices for Installation and Maintenance

The Importance of LPG Hoses Safety, Efficiency, and Versatility

Liquefied Petroleum Gas (LPG) is a widely used fuel across various sectors, from residential cooking and heating to industrial applications. Central to the safe and effective use of LPG is the LPG hose, an essential component that ensures the reliable transfer of gas from storage tanks to appliances. In this article, we will explore the significance of LPG hoses, their features, and the best practices for their maintenance.

What is an LPG Hose?

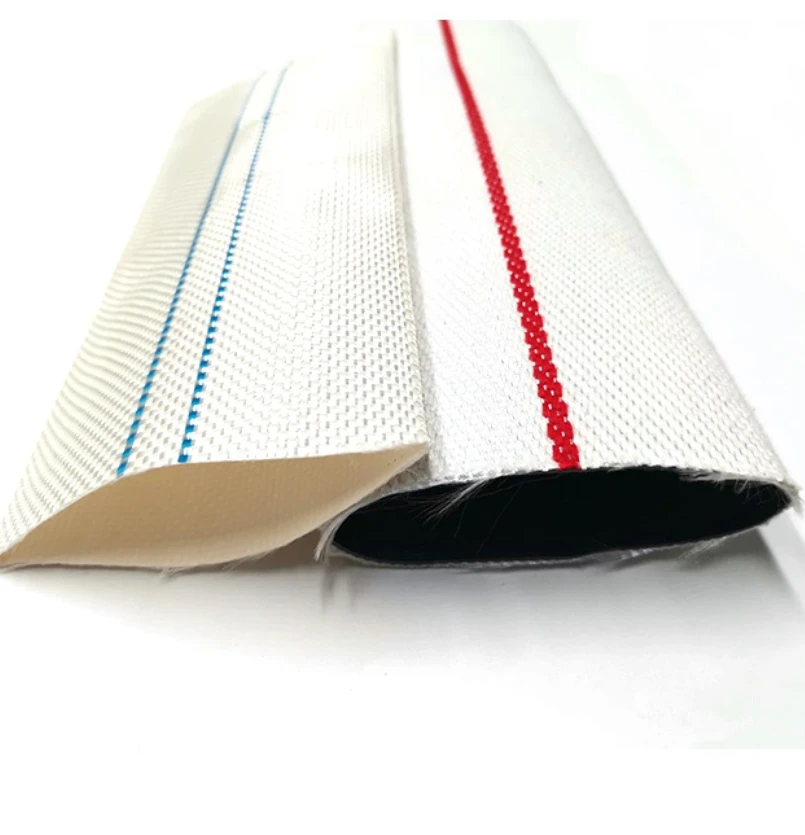

An LPG hose is a specialized tube designed to carry liquefied petroleum gas under high pressure. Often made from rubber, thermoplastic, or a composite material, LPG hoses are built to withstand the extreme conditions associated with gas transfer, including variations in temperature and pressure. These hoses are often reinforced with braided fiber to enhance their strength and durability, ensuring they can handle the rigors of industrial and domestic usage alike.

Safety Standards and Regulations

One of the most crucial aspects of LPG hoses is their compliance with safety standards. The use of LPG is strictly regulated in many countries due to its flammable nature. Standards such as those set by the American National Standards Institute (ANSI) or the British Standard (BS) provide guidelines for the manufacturing and testing of LPG hoses to ensure they are safe for use. These regulations help prevent leaks, which could lead to dangerous situations, including explosions or fires. Therefore, when selecting LPG hoses, it is essential to choose products that meet or exceed these safety standards.

Features of High-Quality LPG Hoses

High-quality LPG hoses possess several key features that enhance their functionality and safety. These include

1. Temperature Resistance LPG hoses should be able to operate safely across a range of temperatures, typically from -20°C to +60°C. This resilience ensures they perform well in various environments, whether in a hot industrial setting or a cooler residential kitchen.

2. Chemical Resistance LPG hoses must resist deterioration from exposure to chemicals and substances found in the environment. This resistance prolongs the life of the hose and ensures its reliability.

3. Flexible Design A good LPG hose should be flexible enough to allow for easy installation and maneuverability without compromising on strength. This flexibility makes it easier to connect to appliances and navigate tight spaces.

lpg hose

4. Fire Resistance Given the flammable nature of LPG, hoses often come with fire-resistant properties. This feature minimizes risks should a fire occur in the vicinity.

5. Burst Pressure Ratings The ability of a hose to withstand significant pressure (burst pressure) is vital. LPG hoses are typically tested against high-pressure scenarios to ensure they won’t burst under extreme conditions.

Maintenance of LPG Hoses

To maximize the lifespan and safety of LPG hoses, regular maintenance is essential. Here are some best practices

- Routine Inspections Regularly inspect hoses for signs of wear and tear, such as cracks, kinks, or abrasions. Any visible damage could indicate a potential failure point.

- Proper Storage When not in use, LPG hoses should be stored in a cool, dry place away from direct sunlight and extreme temperatures. This storage practice helps prevent the degradation of materials.

- Avoid Over-tightening When connecting hoses to appliances or tanks, avoid overtightening, which could lead to damage. Use appropriate fitting tools and follow manufacturer recommendations.

- Replace When Necessary LPG hoses should be replaced according to the manufacturer’s guidelines or at the first sign of damage. Safety should never be compromised for cost savings.

Conclusion

The role of LPG hoses in the safe and efficient use of liquefied petroleum gas cannot be overstated. Their design and construction are critical in preventing leaks and ensuring safe operation across various applications. By adhering to safety standards, selecting high-quality hoses, and maintaining them properly, users can enjoy the benefits of LPG while minimizing risks. Understanding and respecting the importance of LPG hoses is essential for anyone who relies on this versatile fuel source.

-

Top Quality Oxy Acetylene Hoses for Sale Fit for Welding DemandsNewsJul.28,2025

-

The Future of Pneumatic Air Tubes in IndustryNewsJul.28,2025

-

Superior and Reliable LPG Hose Pipe Solutions for Every NeedNewsJul.28,2025

-

Exceptionally Durable and Versatile Premium Braided PVC TubingNewsJul.28,2025

-

Best Adapters for Connecting Garden Hose to PVC Pipe ConnectionsNewsJul.28,2025

-

The Essential Role of LPG Hoses in Safe and Efficient Gas DistributionNewsJul.16,2025