Jun . 18, 2024 04:16

Back to list

Lay the hoses flat and secure.

The Art of Laying Flat Hoses

In the world of plumbing, laying flat hoses is a task that requires precision, patience, and an understanding of the principles that govern water flow. It is an art form that blends practicality with aesthetics, creating a system that is both functional and visually appealing.

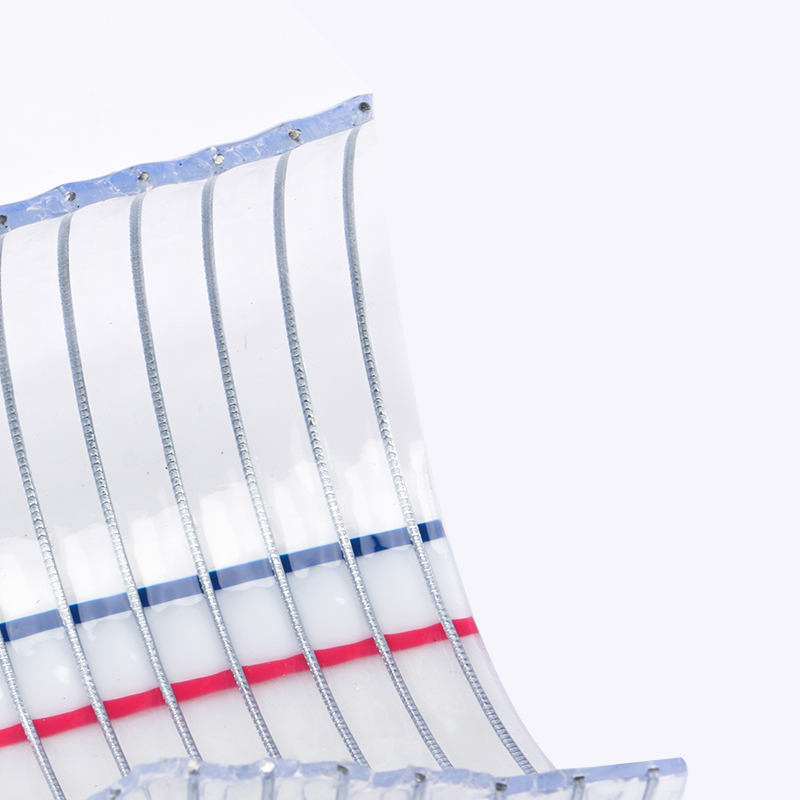

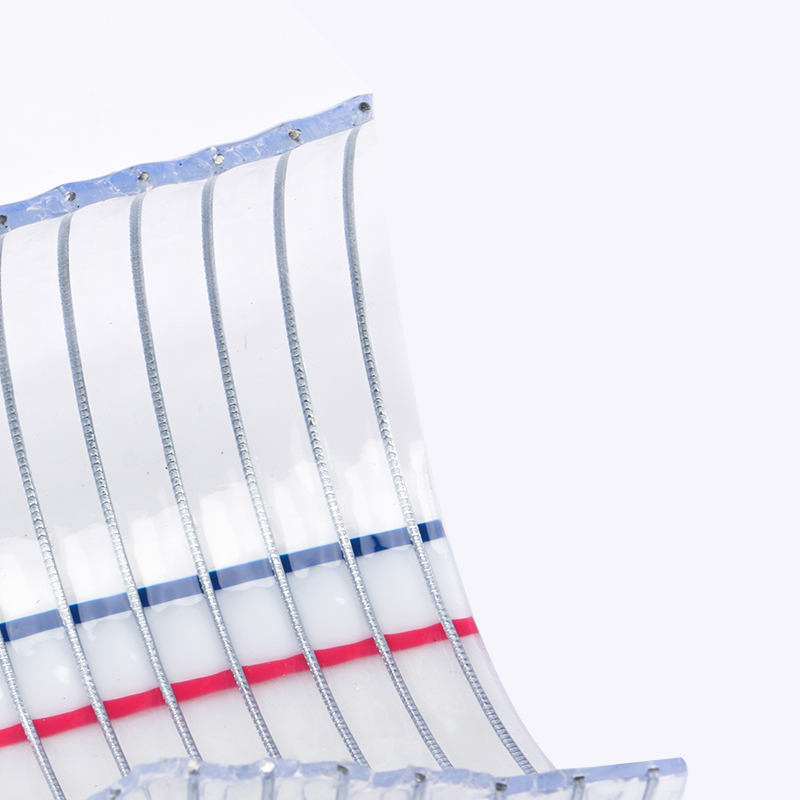

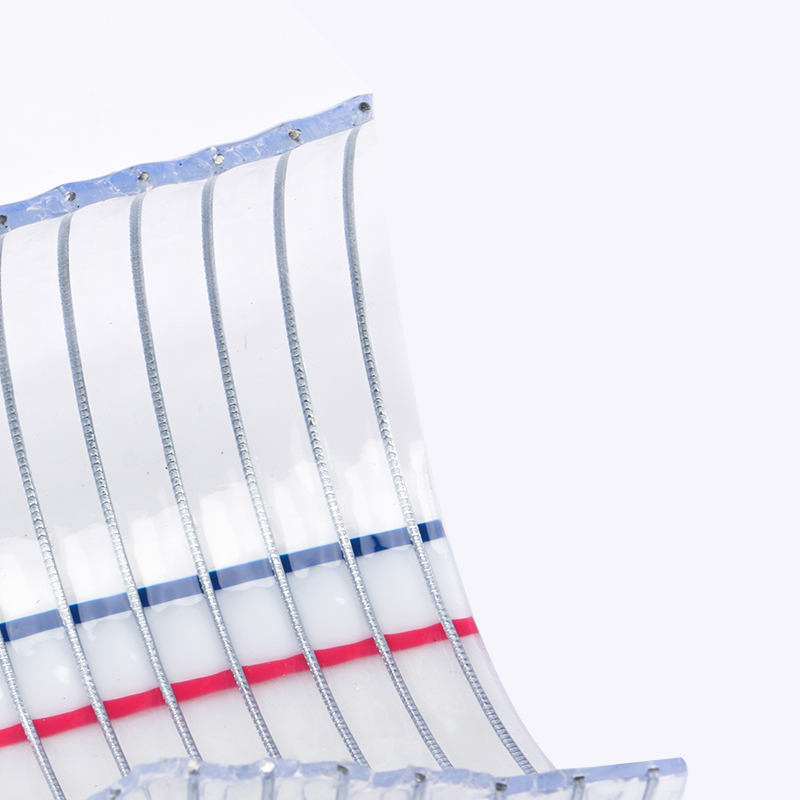

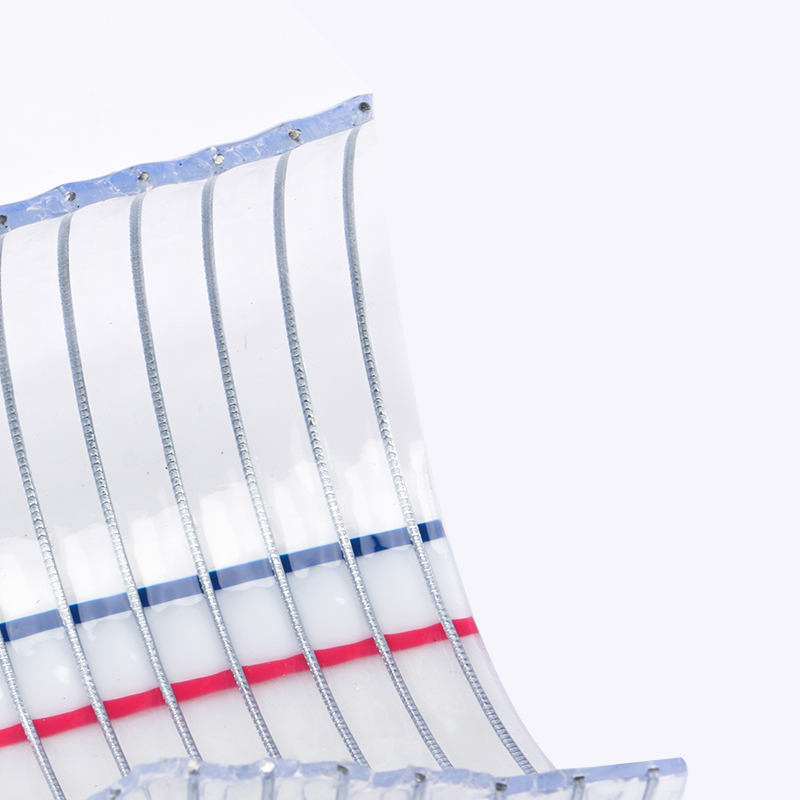

The process begins with selecting the right flat hose. These hoses are designed to provide maximum water flow with minimal space occupation. They are flexible, lightweight, and can be easily routed through tight spaces without compromising their integrity. The material used in their construction is typically a durable blend of synthetic polymers, which ensures resistance to abrasion, chemicals, and extreme temperatures.

Laying flat hoses is not just about connecting point A to point B; it involves a strategic plan to ensure optimal performance. The path of the hose should be as direct as possible to reduce friction loss and maintain water pressure. Bends should be gradual and smooth, avoiding sharp angles that could restrict flow or damage the hose over time.

One crucial aspect is the support system for the hose. Since flat hoses are flexible, they must be properly supported to prevent sagging, kinking, or twisting, which can impede water flow or cause premature failure. Supports can come in various forms, such as clamps, hangers, or even custom-built structures, depending on the application and environment Supports can come in various forms, such as clamps, hangers, or even custom-built structures, depending on the application and environment Supports can come in various forms, such as clamps, hangers, or even custom-built structures, depending on the application and environment Supports can come in various forms, such as clamps, hangers, or even custom-built structures, depending on the application and environment

Supports can come in various forms, such as clamps, hangers, or even custom-built structures, depending on the application and environment Supports can come in various forms, such as clamps, hangers, or even custom-built structures, depending on the application and environment lay flat hoses.

Proper installation also requires attention to detail regarding connections. Fittings must be compatible with the hose's material to avoid leaks. Stainless steel or brass fittings are commonly used due to their durability and resistance to corrosion. The use of thread sealant or tape on the threads before tightening can further prevent leaks at these critical points.

Maintenance is equally important for the longevity of the flat hose system. Regular inspections should be conducted to identify any signs of wear, damage, or potential leaks. Cleanliness is key, as debris or mineral buildup can affect performance and shorten the lifespan of the hose.

In conclusion, laying flat hoses is an art that combines engineering principles with craftsmanship. By selecting the appropriate materials, planning the layout meticulously, installing with care, and maintaining diligently, one can create a plumbing system that is efficient, reliable, and aesthetically pleasing. It is a testament to human ingenuity and our ability to harness nature's resources while minimizing our environmental footprint.

lay flat hoses.

Proper installation also requires attention to detail regarding connections. Fittings must be compatible with the hose's material to avoid leaks. Stainless steel or brass fittings are commonly used due to their durability and resistance to corrosion. The use of thread sealant or tape on the threads before tightening can further prevent leaks at these critical points.

Maintenance is equally important for the longevity of the flat hose system. Regular inspections should be conducted to identify any signs of wear, damage, or potential leaks. Cleanliness is key, as debris or mineral buildup can affect performance and shorten the lifespan of the hose.

In conclusion, laying flat hoses is an art that combines engineering principles with craftsmanship. By selecting the appropriate materials, planning the layout meticulously, installing with care, and maintaining diligently, one can create a plumbing system that is efficient, reliable, and aesthetically pleasing. It is a testament to human ingenuity and our ability to harness nature's resources while minimizing our environmental footprint.

Supports can come in various forms, such as clamps, hangers, or even custom-built structures, depending on the application and environment Supports can come in various forms, such as clamps, hangers, or even custom-built structures, depending on the application and environment

Supports can come in various forms, such as clamps, hangers, or even custom-built structures, depending on the application and environment Supports can come in various forms, such as clamps, hangers, or even custom-built structures, depending on the application and environment lay flat hoses.

Proper installation also requires attention to detail regarding connections. Fittings must be compatible with the hose's material to avoid leaks. Stainless steel or brass fittings are commonly used due to their durability and resistance to corrosion. The use of thread sealant or tape on the threads before tightening can further prevent leaks at these critical points.

Maintenance is equally important for the longevity of the flat hose system. Regular inspections should be conducted to identify any signs of wear, damage, or potential leaks. Cleanliness is key, as debris or mineral buildup can affect performance and shorten the lifespan of the hose.

In conclusion, laying flat hoses is an art that combines engineering principles with craftsmanship. By selecting the appropriate materials, planning the layout meticulously, installing with care, and maintaining diligently, one can create a plumbing system that is efficient, reliable, and aesthetically pleasing. It is a testament to human ingenuity and our ability to harness nature's resources while minimizing our environmental footprint.

lay flat hoses.

Proper installation also requires attention to detail regarding connections. Fittings must be compatible with the hose's material to avoid leaks. Stainless steel or brass fittings are commonly used due to their durability and resistance to corrosion. The use of thread sealant or tape on the threads before tightening can further prevent leaks at these critical points.

Maintenance is equally important for the longevity of the flat hose system. Regular inspections should be conducted to identify any signs of wear, damage, or potential leaks. Cleanliness is key, as debris or mineral buildup can affect performance and shorten the lifespan of the hose.

In conclusion, laying flat hoses is an art that combines engineering principles with craftsmanship. By selecting the appropriate materials, planning the layout meticulously, installing with care, and maintaining diligently, one can create a plumbing system that is efficient, reliable, and aesthetically pleasing. It is a testament to human ingenuity and our ability to harness nature's resources while minimizing our environmental footprint. Latest news

-

Top Quality Oxy Acetylene Hoses for Sale Fit for Welding DemandsNewsJul.28,2025

-

The Future of Pneumatic Air Tubes in IndustryNewsJul.28,2025

-

Superior and Reliable LPG Hose Pipe Solutions for Every NeedNewsJul.28,2025

-

Exceptionally Durable and Versatile Premium Braided PVC TubingNewsJul.28,2025

-

Best Adapters for Connecting Garden Hose to PVC Pipe ConnectionsNewsJul.28,2025

-

The Essential Role of LPG Hoses in Safe and Efficient Gas DistributionNewsJul.16,2025

HOT PRODUCT

Provide You The Highest Quality Work

INQUIRE