Innovative Solutions for Flexible Pneumatic Tubing in Industrial Applications and Automation Systems

The Versatility of Flexible Pneumatic Tubing

In the world of automation and fluid mechanics, flexible pneumatic tubing plays a crucial role in the effective transportation of air and other gases. This innovative material is primarily used within pneumatic systems, which are prevalent in various industries, from manufacturing to automation and even medical applications. The significance of flexible pneumatic tubing cannot be overstated, as it offers numerous advantages that address the evolving needs of modern engineering and production environments.

Composition and Characteristics

Flexible pneumatic tubing is typically made from a range of materials, including polyurethane, polyethylene, and nylon. These materials provide a balance between firmness and flexibility, enabling the tubing to withstand various pressures while accommodating movement and expansion. The inner diameter of flexible tubing can vary, allowing for customization based on the requirements of different applications.

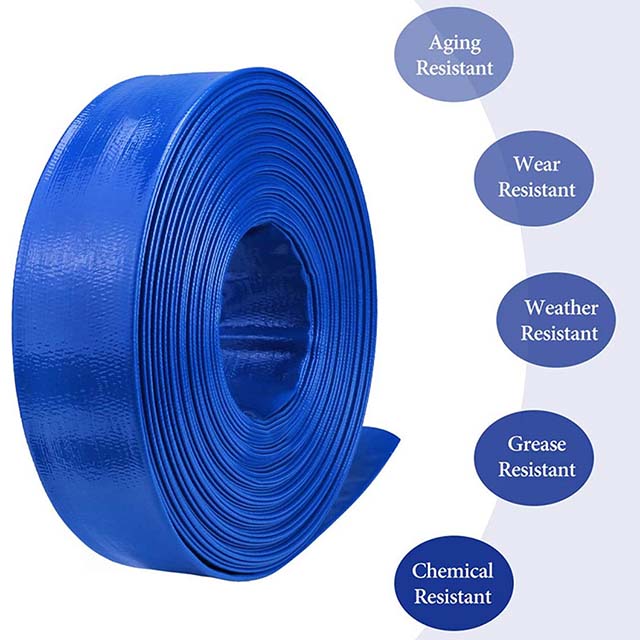

One of the standout features of flexible pneumatic tubing is its ability to maintain integrity under varying temperature and pressure conditions. The tubing is designed to withstand the effects of temperature fluctuations, making it ideal for environments where conditions are less than predictable. Moreover, its resistance to wear, abrasion, and chemicals ensures a long service life, reducing the frequency and cost of replacements.

Applications in Various Industries

Flexible pneumatic tubing finds wide-ranging applications across several sectors. In manufacturing, it is commonly used to connect pneumatic actuators, valves, and other components in automated systems. This enables precise control over movements, allowing for improved efficiency and productivity on the shop floor. For example, in robotic arms used for assembly, flexible tubing ensures that air pressure is accurately delivered, facilitating swift and efficient operation.

In the automotive industry, pneumatic systems featuring flexible tubing are employed in various processes, including painting, assembly, and testing. The reliability of flexible tubing allows for consistent operation, critical in high-stakes environments where precision is key.

flexible pneumatic tubing

The medical field also capitalizes on the benefits of flexible pneumatic tubing. It is used in devices such as ventilators and self-expanding stents, where reliable performance is paramount. The ability to maintain strong connections while allowing for patient mobility is essential, and flexible tubing meets these stringent requirements effectively.

Benefits of Using Flexible Pneumatic Tubing

One of the primary benefits of flexible pneumatic tubing is its lightweight nature. This characteristic not only simplifies installation but also reduces the energy requirements of the systems to which it is connected. The flexibility of the material allows for easy routing around existing machinery and equipment, thereby facilitating straightforward maintenance and adjustments.

Additionally, flexible pneumatic tubing is capable of handling higher flow rates, which can significantly enhance the performance of pneumatic systems. As compressed air moves through these tubes with minimal resistance, systems can operate more efficiently, leading to reduced energy consumption.

The ease of installation and adaptability of flexible pneumatic tubing also contribute to faster system assembly. Unlike rigid materials, flexible tubing can be cut to size on-site, allowing for tailored solutions that meet specific needs without the necessity for extensive modifications to existing setups.

Conclusion

In summary, flexible pneumatic tubing is an indispensable asset in various industries, offering unmatched flexibility, durability, and performance. Its wide applicability, coupled with the benefits of lightweight construction and ease of installation, makes it a preferred choice for engineers and manufacturers alike. As technology continues to evolve, the reliance on flexible pneumatic tubing is expected to grow, further solidifying its place as a key component in the future of pneumatic systems and automation. By investing in versatile tubing solutions, industries can enhance operational efficiency, reduce costs, and meet the demands of a rapidly changing market.

-

Welded Wire Mesh Panel: Durable, Versatile, and AffordableNewsJul.28,2025

-

Top Quality Oxy Acetylene Hoses for Sale Fit for Welding DemandsNewsJul.28,2025

-

The Future of Pneumatic Air Tubes in IndustryNewsJul.28,2025

-

Superior and Reliable LPG Hose Pipe Solutions for Every NeedNewsJul.28,2025

-

Exceptionally Durable and Versatile Premium Braided PVC TubingNewsJul.28,2025

-

Best Adapters for Connecting Garden Hose to PVC Pipe ConnectionsNewsJul.28,2025