hose oxygen acetylene

Understanding the Basics of Hose for Oxygen and Acetylene Use

In the world of welding and cutting metals, the combination of oxygen and acetylene gases plays a critical role. These two gases, when mixed in the right proportions, create a flame that can reach extremely high temperatures, making them ideal for various industrial applications. However, handling these gases necessitates the use of specialized hoses that are designed to ensure safety and efficiency during operations.

Oxygen and acetylene hoses are specifically engineered to withstand the unique demands of high-pressure gas handling. The hoses must be able to endure the pressures exerted by both gases, which can range anywhere from a few pounds per square inch (psi) to more than 100 psi. Standard rubber hoses cannot be used for this purpose, as they are often not rated for high-pressure applications or resistant to the corrosive nature of these gases.

Understanding the Basics of Hose for Oxygen and Acetylene Use

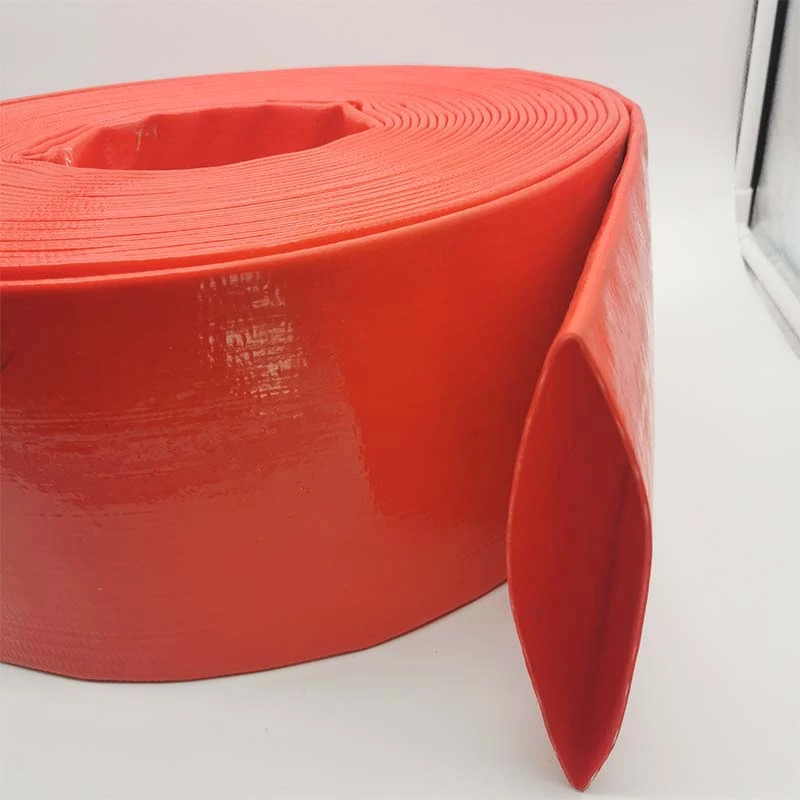

The typical construction of these hoses involves multiple layers of reinforced rubber or thermoplastic that provide a robust barrier against the gases. For example, high-grade synthetic rubber is often used because it is both flexible and durable. This adaptability is essential for the welder or fabricator who needs to maneuver the hose easily around workspaces.

hose oxygen acetylene

In addition to selecting the right hose for gas types, operators must also be diligent in examining their hoses regularly for signs of wear or damage. Cracks, frays, or any signs of discoloration can be indicators that the hose is compromised and should be replaced immediately. Failing to maintain hoses can result in gas leaks that may lead to hazardous situations, including fire hazards or equipment damage.

Another important aspect is the proper storage and handling of hoses. Hoses should be stored in a cool, dry place and should never be left in direct sunlight or exposed to harsh weather conditions for extended periods. This can degrade the material and reduce its effectiveness. When using the hoses, operators should avoid excessive bending or kinking, as this can severely affect the internal structure and performance of the hose.

Moreover, proper training in the use of oxygen and acetylene systems is crucial. Workers must understand the risks associated with welding and cutting processes, including the necessity of using personal protective equipment (PPE), such as goggles or face shields, to safeguard against sparks and high heat.

In conclusion, while oxygen and acetylene gases are invaluable in metalworking and construction, the safe and effective use of these gases relies heavily on the proper selection and maintenance of hoses. By understanding the importance of using the correct hoses, regularly inspecting them, and adhering to safety protocols, operators can create a safer work environment and enhance the efficiency of their welding and cutting operations. Properly managed, oxygen and acetylene can enable us to perform remarkable feats in metal fabrication while minimizing risks associated with their use.

-

Top Quality Oxy Acetylene Hoses for Sale Fit for Welding DemandsNewsJul.28,2025

-

The Future of Pneumatic Air Tubes in IndustryNewsJul.28,2025

-

Superior and Reliable LPG Hose Pipe Solutions for Every NeedNewsJul.28,2025

-

Exceptionally Durable and Versatile Premium Braided PVC TubingNewsJul.28,2025

-

Best Adapters for Connecting Garden Hose to PVC Pipe ConnectionsNewsJul.28,2025

-

The Essential Role of LPG Hoses in Safe and Efficient Gas DistributionNewsJul.16,2025