Feb . 02, 2025 00:48

Back to list

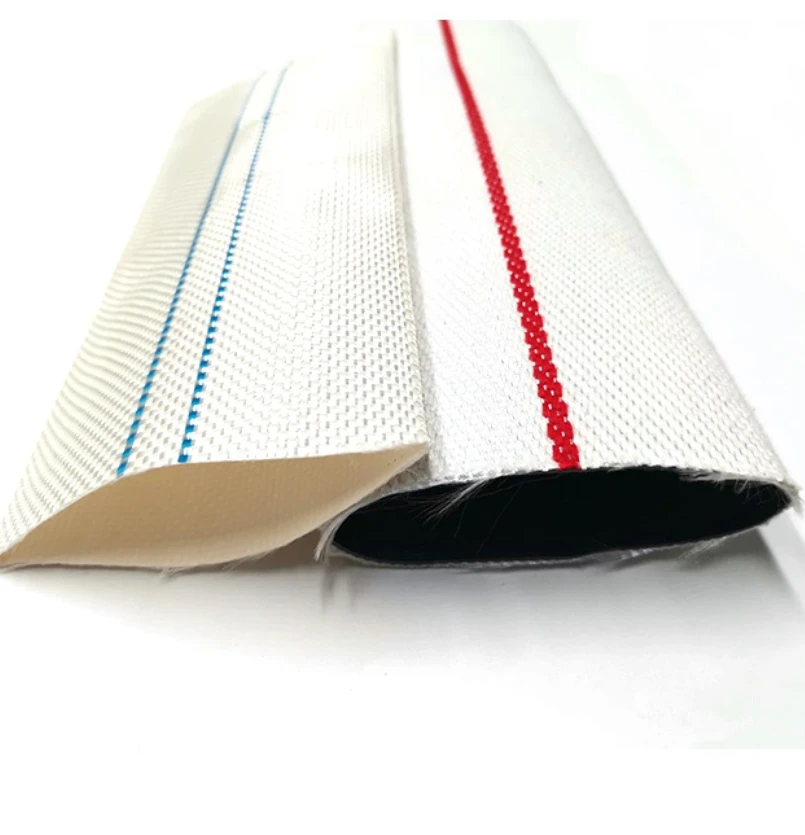

high pressure pneumatic tubing

High pressure pneumatic tubing plays a pivotal role in various industrial applications where the safe and efficient transfer of gases is crucial. Manufactured to withstand significant pressure levels, these tubing solutions are integral to sectors such as manufacturing, construction, automotive, and aerospace.

In terms of recent advancements, the integration of smart sensor technology into high pressure pneumatic systems has been a game changer. These sensors monitor parameters such as pressure, temperature, and leak detection in real-time, providing users with critical data that can prevent system failures and optimize maintenance schedules. By harnessing the power of the Internet of Things (IoT), companies can achieve enhanced operational efficiency and safety. The automotive industry, with its stringent demands for precision and reliability, relies heavily on high pressure pneumatic tubing in its manufacturing processes. For instance, it is central to air brake systems, where any compromise can directly affect vehicle safety. Similarly, in the aerospace sector, where every component must pass strict compliance tests, the use of high performance pneumatic tubing is non-negotiable. Such tubing is employed in actuating systems and hydraulic controls, where failure is not an option. To cultivate trust and authority in the market, it is imperative for manufacturers and suppliers of high pressure pneumatic tubing to establish their credentials. They should provide comprehensive documentation on product certifications, compliance data, and case studies that highlight successful implementations. Open channels for customer feedback and support can also significantly enhance trustworthiness. High pressure pneumatic tubing is an indispensable component of modern industrial applications. When selected and managed effectively, it not only enhances performance but also assures safety and reliability in complex systems. The combination of superior materials, advanced technology, and a strong commitment to quality makes it possible to overcome the challenges posed by high pressure environments. To ensure optimal outcomes, those in need of pneumatic tubing should prioritize quality and consult with experienced professionals to tailor solutions that align perfectly with their operational demands.

In terms of recent advancements, the integration of smart sensor technology into high pressure pneumatic systems has been a game changer. These sensors monitor parameters such as pressure, temperature, and leak detection in real-time, providing users with critical data that can prevent system failures and optimize maintenance schedules. By harnessing the power of the Internet of Things (IoT), companies can achieve enhanced operational efficiency and safety. The automotive industry, with its stringent demands for precision and reliability, relies heavily on high pressure pneumatic tubing in its manufacturing processes. For instance, it is central to air brake systems, where any compromise can directly affect vehicle safety. Similarly, in the aerospace sector, where every component must pass strict compliance tests, the use of high performance pneumatic tubing is non-negotiable. Such tubing is employed in actuating systems and hydraulic controls, where failure is not an option. To cultivate trust and authority in the market, it is imperative for manufacturers and suppliers of high pressure pneumatic tubing to establish their credentials. They should provide comprehensive documentation on product certifications, compliance data, and case studies that highlight successful implementations. Open channels for customer feedback and support can also significantly enhance trustworthiness. High pressure pneumatic tubing is an indispensable component of modern industrial applications. When selected and managed effectively, it not only enhances performance but also assures safety and reliability in complex systems. The combination of superior materials, advanced technology, and a strong commitment to quality makes it possible to overcome the challenges posed by high pressure environments. To ensure optimal outcomes, those in need of pneumatic tubing should prioritize quality and consult with experienced professionals to tailor solutions that align perfectly with their operational demands.

Next:

Latest news

-

Welded Wire Mesh Panel: Durable, Versatile, and AffordableNewsJul.28,2025

-

Top Quality Oxy Acetylene Hoses for Sale Fit for Welding DemandsNewsJul.28,2025

-

The Future of Pneumatic Air Tubes in IndustryNewsJul.28,2025

-

Superior and Reliable LPG Hose Pipe Solutions for Every NeedNewsJul.28,2025

-

Exceptionally Durable and Versatile Premium Braided PVC TubingNewsJul.28,2025

-

Best Adapters for Connecting Garden Hose to PVC Pipe ConnectionsNewsJul.28,2025

HOT PRODUCT

Provide You The Highest Quality Work

INQUIRE