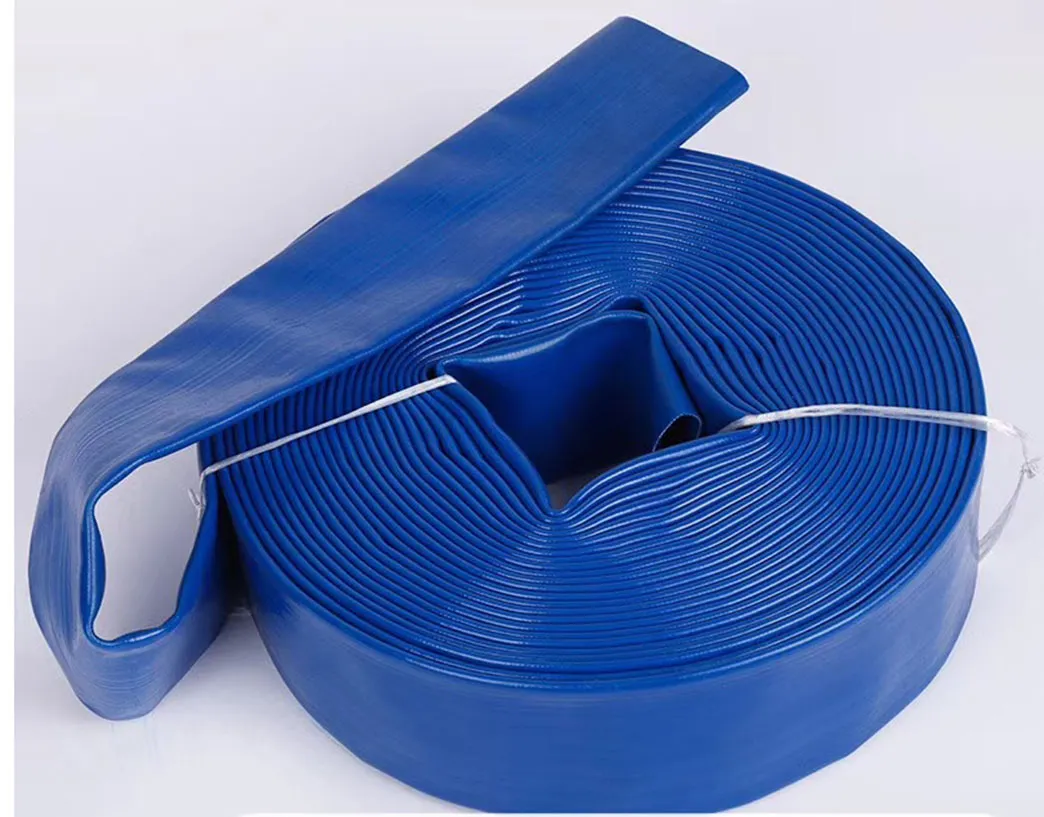

high pressure pneumatic hose

The Importance of High-Pressure Pneumatic Hoses in Industrial Applications

High-pressure pneumatic hoses play a crucial role in various industrial applications, particularly in sectors that rely on the transfer of compressed air for operations. These hoses are designed to withstand high pressures, ensuring that the tools and machinery function efficiently and safely. Understanding the features and uses of high-pressure pneumatic hoses is essential for businesses that depend on pneumatic systems.

What Are High-Pressure Pneumatic Hoses?

High-pressure pneumatic hoses are specially designed tubes that deliver compressed air to pneumatic tools and equipment. Made from durable materials such as rubber, polyurethane, or thermoplastic, these hoses can endure high pressure and extreme conditions. They come with reinforced layers to prevent bursting, allowing them to handle pressures ranging from 300 psi to over 5,000 psi, depending on the application.

Key Features

1. Durability The materials used in high-pressure pneumatic hoses are selected for their ability to withstand wear and tear. They resist abrasion, ozone, and UV light, which prolongs their lifespan.

2. Flexibility Despite their robust construction, these hoses retain flexibility, allowing for easy maneuverability in tight spaces. This characteristic is particularly important in dynamic environments where hoses must be moved frequently.

4. Safety Safety is paramount in any industrial setting. High-pressure hoses are often equipped with safety features such as burst-resistant designs and fittings that minimize the risk of leaks and accidents.

high pressure pneumatic hose

Applications

High-pressure pneumatic hoses are employed in a variety of industries, including

- Manufacturing In manufacturing processes, pneumatic tools such as air-powered drills, saws, and impact wrenches are used extensively. High-pressure hoses ensure a steady flow of air to these tools, improving productivity and efficiency.

- Construction In the construction industry, pneumatic tools are vital for tasks ranging from drilling to demolition. High-pressure hoses facilitate the efficient operation of these tools, making construction projects safer and quicker.

- Automotive In automotive workshops, high-pressure pneumatic hoses are used for tire inflation, paint spraying, and powering pneumatic wrenches. Their reliability is crucial for maintaining productivity in fast-paced environments.

Maintenance Tips

To ensure longevity and optimal performance of high-pressure pneumatic hoses, regular maintenance is essential. Users should inspect hoses for signs of wear, damage, or leaks. Proper storage is also important; hoses should be kept coiled and free from kinks or sharp bends. Additionally, using the correct fittings and connectors will help maintain the integrity of the hose and prevent accidents.

Conclusion

High-pressure pneumatic hoses are indispensable in many industrial applications, providing the necessary power for a wide range of tools and equipment. By understanding their features, applications, and maintenance needs, businesses can optimize their use, enhancing safety and productivity in their operations. Investing in high-quality hoses is not just a choice; it is a necessity for any industry relying on pneumatic systems.

-

Top Quality Oxy Acetylene Hoses for Sale Fit for Welding DemandsNewsJul.28,2025

-

The Future of Pneumatic Air Tubes in IndustryNewsJul.28,2025

-

Superior and Reliable LPG Hose Pipe Solutions for Every NeedNewsJul.28,2025

-

Exceptionally Durable and Versatile Premium Braided PVC TubingNewsJul.28,2025

-

Best Adapters for Connecting Garden Hose to PVC Pipe ConnectionsNewsJul.28,2025

-

The Essential Role of LPG Hoses in Safe and Efficient Gas DistributionNewsJul.16,2025