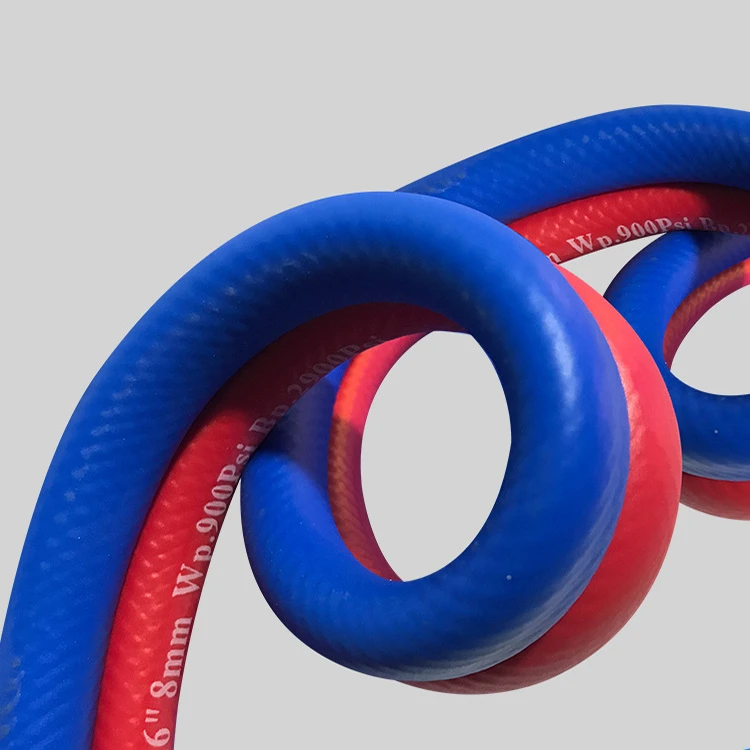

high pressure braided pvc tubing

High Pressure Braided PVC Tubing A Comprehensive Overview

When it comes to industrial and commercial applications, the choice of tubing is crucial for ensuring performance, durability, and safety. Among the various options available, high pressure braided PVC tubing stands out due to its unique blend of strength, flexibility, and resistance to various environmental factors. In this article, we will delve into the characteristics, applications, benefits, and considerations of using high pressure braided PVC tubing.

Characteristics

High pressure braided PVC tubing is constructed from polyvinyl chloride (PVC), which is known for its versatility and resilience. The “braided” aspect refers to the reinforcement incorporated within the tubing, which is typically made from polyester or nylon fibers. This braiding provides additional strength and can withstand high-pressure conditions, making it suitable for a wide range of demanding applications.

One of the standout features of this type of tubing is its ability to handle pressures that can exceed several hundred psi (pounds per square inch). Depending on the thickness and braiding techniques used, high pressure PVC tubing can maintain its structure and performance under both static and dynamic pressures.

Applications

The versatility of high pressure braided PVC tubing makes it suitable for various applications across different industries. Some common uses include

1. Food and Beverage In this sector, the tubing is often employed for transferring liquids, thanks to its compliance with food safety standards. It is resistant to both UV light and chemicals, ensuring that the integrity of the product is maintained during transport.

2. Agriculture High pressure braided PVC tubes are widely used in irrigation systems and agricultural spraying equipment. The tubing's resistance to abrasion and environmental conditions makes it an ideal choice for outdoor use.

3. Automotive Within the automotive industry, this tubing finds applications in fuel lines, brake systems, and coolant transfer. Its strength and flexibility allow for reliable performance even in high-stress scenarios.

4. Construction and Heavy Machinery The tubing is commonly used in hydraulic systems and as a conduit for various fluids, ensuring efficient operation of equipment.

Benefits

high pressure braided pvc tubing

Choosing high pressure braided PVC tubing offers numerous advantages for users

. Some of the key benefits include- Durability The reinforced structure provides enhanced resistance to punctures, abrasions, and environmental factors such as UV rays and chemicals.

- Flexibility Despite its strength, the tubing remains highly flexible, allowing for easy installation and maneuverability in tight spaces.

- Chemical Resistance High pressure PVC tubing can resist exposure to various chemicals, making it suitable for diverse applications where fluid compatibility is a concern.

- Lightweight Design Compared to metal tubing, PVC is considerably lighter, which can help reduce overall equipment weight and improve efficiency.

Considerations

While high pressure braided PVC tubing has many advantages, it is essential to consider certain factors before use

- Temperature Limits Users must ensure that the tubing remains within its temperature tolerance to prevent deformation or failure.

- Pressure Rating It is crucial to select tubing that meets or exceeds the specific pressure requirements of the application to ensure safety and reliability.

- Compatibility Users should verify that the tubing is compatible with the fluids or materials it will be in contact with to avoid degradation.

Conclusion

High pressure braided PVC tubing is a valuable asset in numerous industries, offering strength, flexibility, and reliability. Its ability to perform under high-pressure conditions while resisting environmental challenges makes it a go-to choice for engineers and manufacturers alike. When selecting tubing for your specific needs, always consider the application requirements, pressure ratings, and compatibility to ensure optimal performance. By doing so, you can fully leverage the benefits of this versatile material for your operations.

-

Top Quality Oxy Acetylene Hoses for Sale Fit for Welding DemandsNewsJul.28,2025

-

The Future of Pneumatic Air Tubes in IndustryNewsJul.28,2025

-

Superior and Reliable LPG Hose Pipe Solutions for Every NeedNewsJul.28,2025

-

Exceptionally Durable and Versatile Premium Braided PVC TubingNewsJul.28,2025

-

Best Adapters for Connecting Garden Hose to PVC Pipe ConnectionsNewsJul.28,2025

-

The Essential Role of LPG Hoses in Safe and Efficient Gas DistributionNewsJul.16,2025