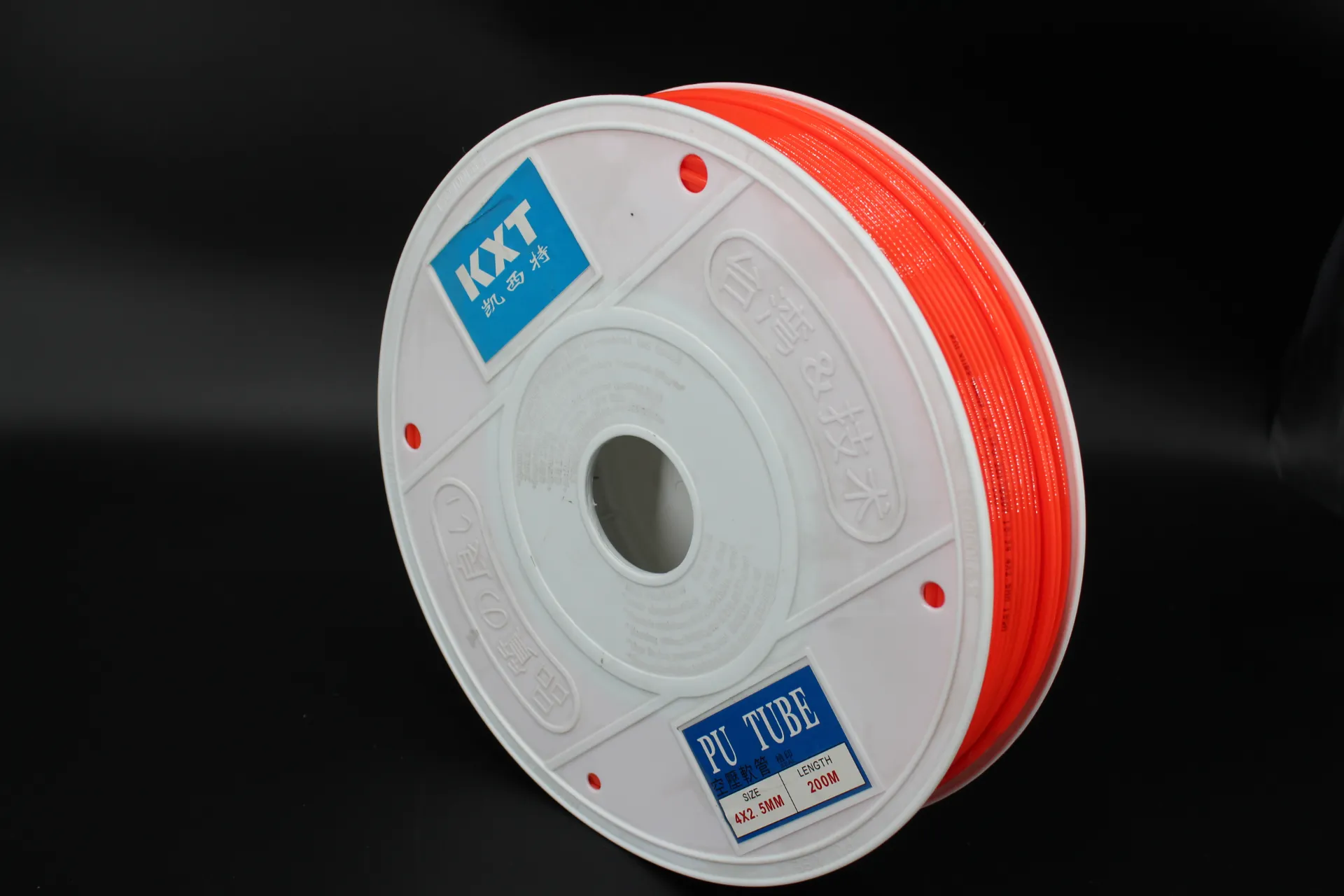

High-Quality Polyurethane Tube - Durable Tubing at Competitive Price

Website: https://www.kebinghose.com

In the modern industrial landscape, the polyurethane tube stands out as a flexible, high-performance solution for air, pneumatic, and fluid transport applications. With growing demands across automation, automotive, electronics, food & beverage, and general manufacturing sectors, choosing a high-quality polyurethane tube directly impacts performance, safety, and cost efficiency.

Hebei Kebing Import and Export Trade Co., LTD supplies advanced polyurethane tubing variants, constantly adopting international standards and the latest materials engineering breakthroughs. This comprehensive guide delves into polyurethane tube industry trends, pricing, technical specifications, applications, and how to choose the ideal polyurethane tubing supplier.

The global polyurethane tube market is expanding, fueled by automation, miniaturization of machinery, and environmental regulations favoring lightweight, efficient materials.

According to the MarketsandMarkets™ research, polyurethane tubing demand is expected to increase by a CAGR of 5.6% by 2028, especially within pneumatic automation (ISO 7863:2016): "Polyurethane tubes provide exceptional flexibility and service life, outperforming traditional PVC and rubber hoses in high-cycle industrial automation."

Advanced applications in robotics, food-grade transport, and paint spraying are rapidly adopting polyurethane tubing due to enhanced abrasion resistance, flexibility, and chemical compatibility.

| Parameter | Range | Industry Standard | Significance |

|---|---|---|---|

| Material | Pure/ether-based/polyether/polyester PU | ASTM D638, ISO 7863 | Defines flexibility, chemical resistance |

| Operating Temperature | -40ºC to +90ºC | ISO 5359, DIN 74324 | Safe working temperature range |

| Working Pressure | Up to 10-16 Bar (150-232 PSI) | ISO 10619-2 | Max continuous safe pressure |

| Burst Pressure | ≥30 Bar (440 PSI) | DIN EN ISO 1402 | Peak pressure safety margin |

| Bend Radius | 3mm–22mm (ID & type related) | ASTM D380 | Minimum safe bend |

| Color | Red, Blue, Green, Yellow, Black, Custom | BS EN 60695 | Color coding, aesthetics, safety |

| Toxicity/Odor | Non-toxic, Odorless | FDA, REACH, RoHS | Compliance for sensitive use |

| Elasticity | Excellent (100%+ elongation @ break) | ISO 527 | Ease of routing; space-saving |

Product Name: Hot Sale Air Hose/22 Coils Spring Coil/PA Air Hose/PU Air Hose

Construction: Nylon, Polyurethane.

Color Options: Red, Blue, Green, Yellow, Black, Custom.

Operating Temperature: -40ºC to +90ºC.

Key Features: Good elasticity, easy to operate, space-saving, impact absorption, non-toxic, odorless, high flexibility, tight bending radius, custom specs available.

Product Page: Polyurethane Tube - Full Specs & Order Here

Radar Chart: Hot Sale Polyurethane Tube vs Market Average

The polyurethane tube price is influenced by raw material quality, internal diameter, wall thickness, working pressure, and custom processing requirements.

For bulk procurement from a professional polyurethane tubing supplier like Hebei Kebing, price typically ranges between $0.08~$0.30 per meter for standard air hose sizes (reference). Customization, FDA approval, or anti-static features will affect price.

We recommend contacting admin@kebinghose.com for the latest quotations and bulk order discounts.

- ISO 9001 certified manufacturing management, strict quality control.

- Global exports, reliable supply chain, short lead timings.

- Custom color, size, printing, and coil shapes available.

- Professional engineering team for design and technical support.

- Competitive polyurethane tube price and after-sale service.

- Industrial Pneumatics and Robotics

- Automotive Air Braking & Controls

- Compressed Air Tools & Equipment

- Food Grade Conveyance (per FDA/REACH/ROHS)

- Painting, Fluid Transfer, Spray Systems

- Prototyping, Laboratory, Medical Devices

- Electronics Assembly Lines

- Comply with ISO 7863:2016 Polyurethane Tubing Standards

- Check compatibility with fittings (NPT/BSP/G-thread/Push-in)

- Maintain designated minimum bend radius and safe pressure

- Avoid exposure to high ozone, organic solvents, direct sunlight for extended periods

- Tightly secure, prevent kinking, and periodically inspect tubing

- Replace tube if burst, cracks, or hardening signs are found

The polyurethane tubing segment is regulated and guided by multiple international forums and technical journals that discuss best practices, latest research, and upcoming trends. For instance:

- ScienceDirect Journal: "Review of Polyurethane Engineering and Properties" – Discusses latest composite polyurethane tubing innovations and durability outcomes.

- ResearchGate: "Design and Fabrication of Polyurethane Tubing for Industrial Applications"

- HoseTalk Forum: "Polyurethane Tube vs. PVC Hose in Automation"

- Polyurethane Manufacturers Association (PMA) – Global community for standards and compliance updates.

[1] MarketsandMarkets™ - Polyurethane Tube Market Outlook: https://www.marketsandmarkets.com/Market-Reports/polyurethane-market-1205.html

[2] ISO 7863:2016 Polyurethane Tubing Standard: https://www.iso.org/standard/30704.html

[3] ScienceDirect - "Review of Polyurethane Engineering": https://www.sciencedirect.com/science/article/pii/S0261306919312115

[4] HoseTalk Industry Forum: https://forum.hosetalk.com/topics/polyurethane-tube-vs-pvc

[5] ResearchGate - Polyurethane Tubing Fabrication: https://www.researchgate.net/publication/337917472_Design_and_Fabrication_of_Polyurethane_Tubing_for_Industrial_Applications

[6] PMA - Polyurethane Manufacturers Association: https://www.polyurethane.org/

-

The Essential Role of LPG Hoses in Safe and Efficient Gas DistributionNewsJul.16,2025

-

The Crucial Role and Varieties of LPG Gas HosesNewsJul.16,2025

-

PVC Flexible Hoses in Industrial Applications: A Comprehensive OverviewNewsJul.16,2025

-

High - Pressure LPG Hoses - Ensuring Safety and Efficiency in Fuel TransferNewsJul.16,2025

-

Essential Tools for Welding Operations: Oxy - Acetylene HosesNewsJul.16,2025

-

Essential Connections - LP Gas Hoses and Their VariantsNewsJul.16,2025